Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form. To delete your registration, please visit here.

All

All

Since the 1990s, communication technology has rapidly advanced, and specifically, the digitization of broadcasting has greatly accelerated the convergence of communication and broadcasting. This evolution has popularized broadcasting and video playback on mobile terminals, leading to a tremendous increase in wireless communication demand. Our company has been developing our business by utilizing GaN-HEMT and advanced signal processing technology to achieve high efficiency in high-power amplifiers for mobile base stations in communication systems. This paper focuses on the digital and analog signal processing technologies that form the basis of these communication systems, highlighting the currently widely used Orthogonal Frequency Division Multiplexing (OFDM) system. It also describes the technological development of communication systems, amplifiers, and GaN-HEMT models, along with future prospects.

3.7 MB

3.7 MB

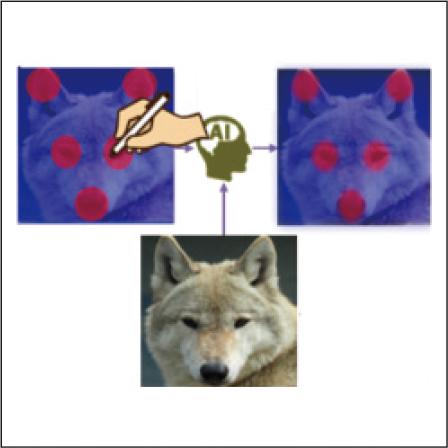

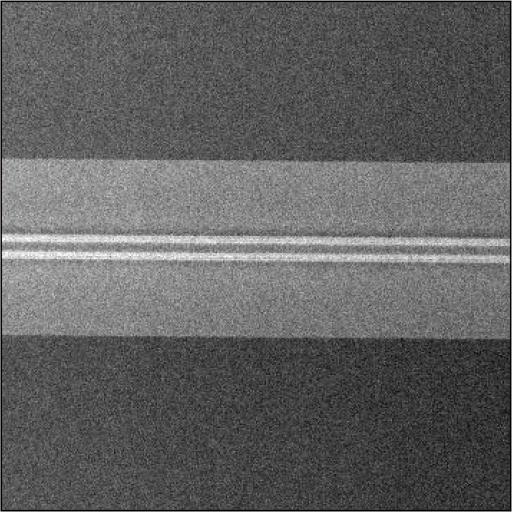

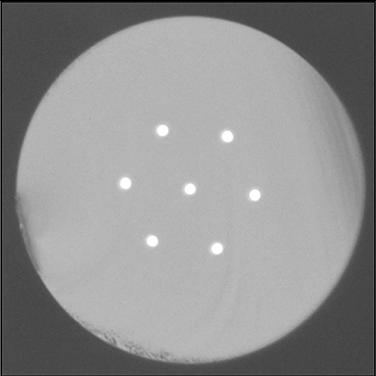

With the rapid development of AI technology, autonomous driving is becoming a reality. To achieve this, it is important to have a comprehensive view of road and parking area conditions. However, achieving sufficient coverage is challenging because probe information is limited by data privacy concerns and road sensors are installed only on major roads. To address these challenges, we proposed an algorithm to detect vehicles using monochromatic images observed by an all-weather radar called Synthetic Aperture Radar (SAR). We evaluated the algorithm by comparing its results on SAR satellite images with vehicle counts obtained through visual inspection. This paper reports the results and discusses the challenges encountered in the process.

1.8 MB

1.8 MB

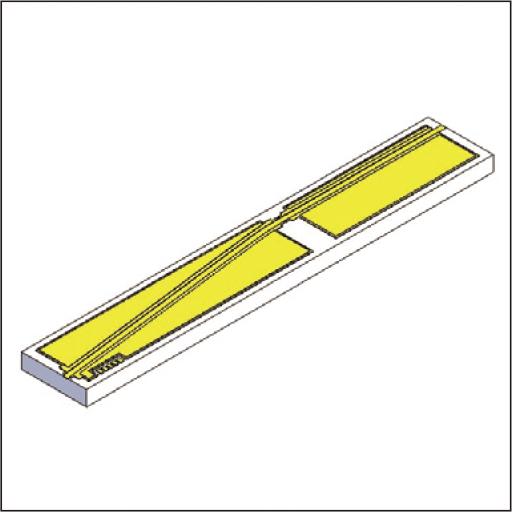

As production numbers of battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs), and hybrid electric vehicles (HEVs) increase, the development of eAxle, which integrate motors, gears, and inverters, is accelerating. Although busbars currently dominate power supply harnesses to eAxle motors, there is a growing demand for flexible cables that offers superior vibration resistance and greater design freedom. Thus, we developed an easily deployable flexible cable, specifically for the power supply of oil-cooled eAxle motors. We selected fluoro rubber as the flexible insulating material due to its excellent resistance to ATF, which serves as both a refrigerant and a lubricant. However, we faced challenges in balancing flexibility with properties such as abrasion resistance and the prevention of adhesion between insulating materials. We addressed these issues by achieving the fine dispersion of crystalline components to enhance abrasion resistance and by controlling molecular mobility through cross-linking to reduce the adhesion of insulations. Through this study, we were able to develop a cable that meets the ISO 200°C rating, has ATF resistance and flexibility, and put it on the market.

1.5 MB

1.5 MB

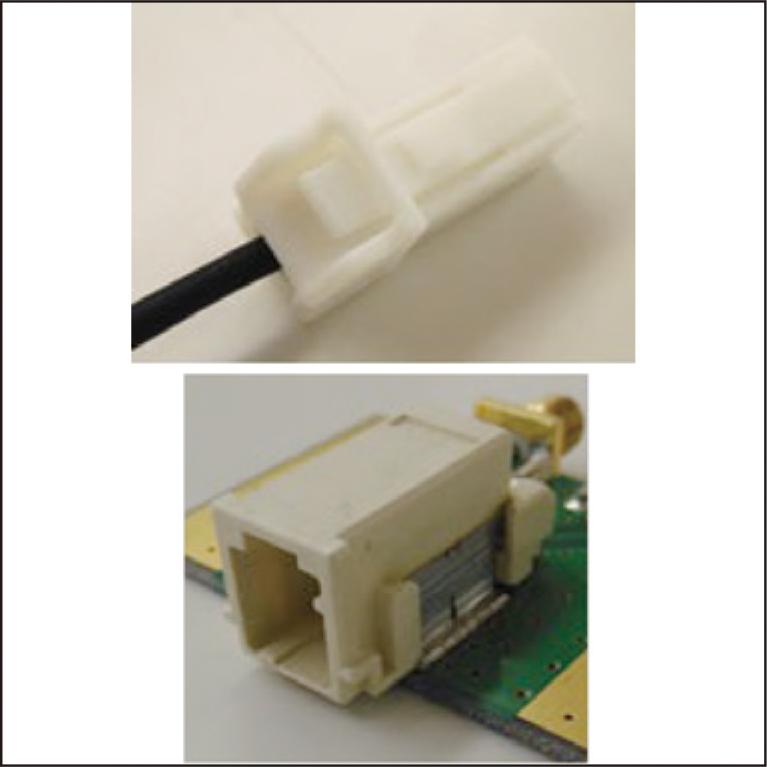

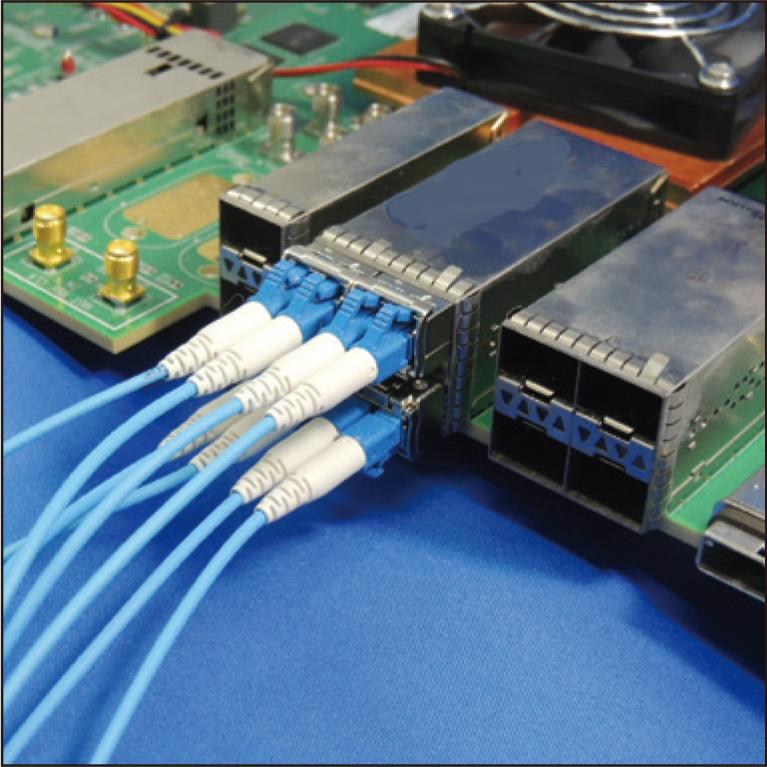

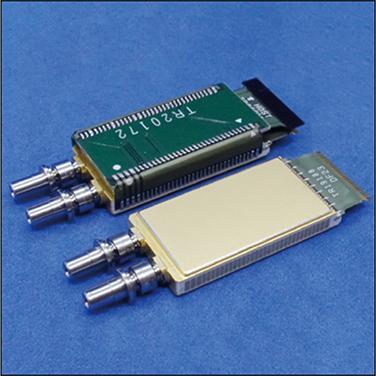

The NTT proposes the IOWN concept as the next generation of information and communications infrastructure, characterized by low latency (1/200), high capacity (125 times greater transmission capacity), and energy efficiency (100 times improved power efficiency) based on an all-photonics network (APN). Through the activities of the IOWN Global Forum (IOWN GF), diverse companies from various industries worldwide participate in discussions regarding technologies and use cases for social implementation. These discussions are then presented to standardization organizations. Particularly, this enhanced low latency aims to facilitate previously impossible video services and contribute to advancements in data center configurations and financial systems. The Broad Networks (BNS) Division is actively developing foundational technologies and products for new market opportunities. As part of this effort, we developed an ultra-low latency media converter (LLMC) that leverages the characteristics of the IOWN APN. This paper reports on the design philosophy and the measured low latency performance achieved in accordance with the target specifications defined in the IOWN GF AI-assisted Entertainment Interactive Live Music (ILM) use case.

1.9 MB

1.9 MB

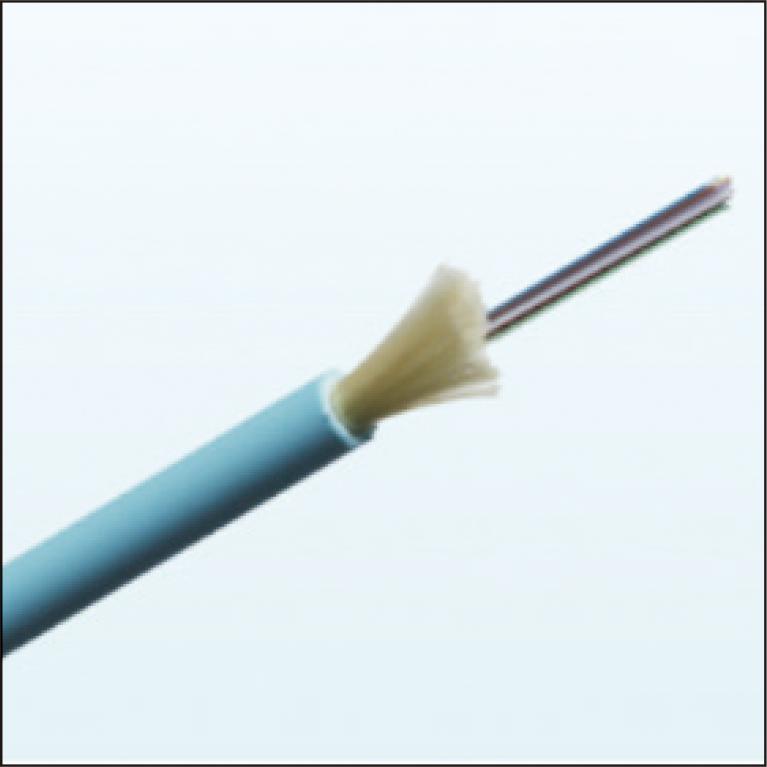

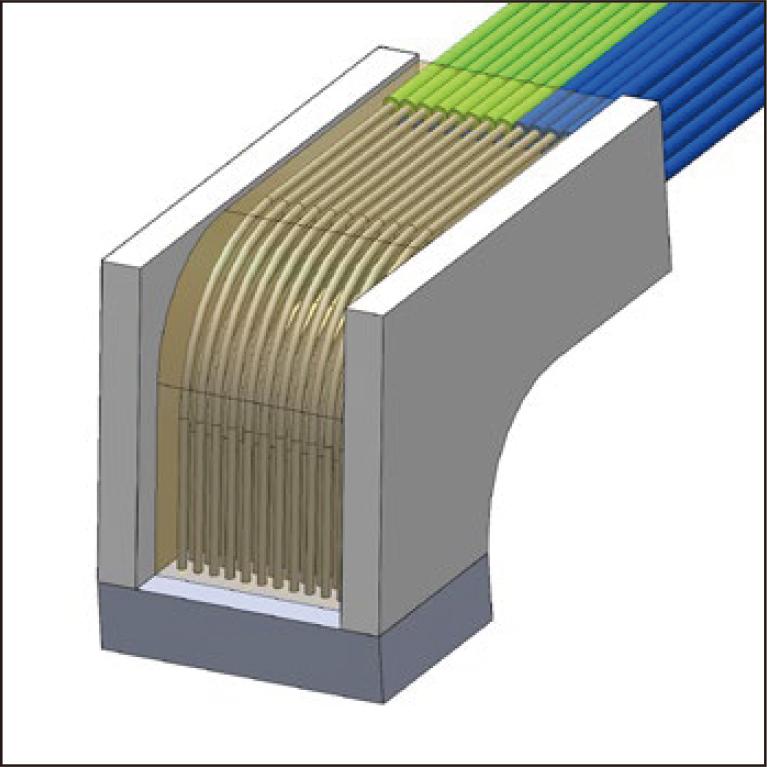

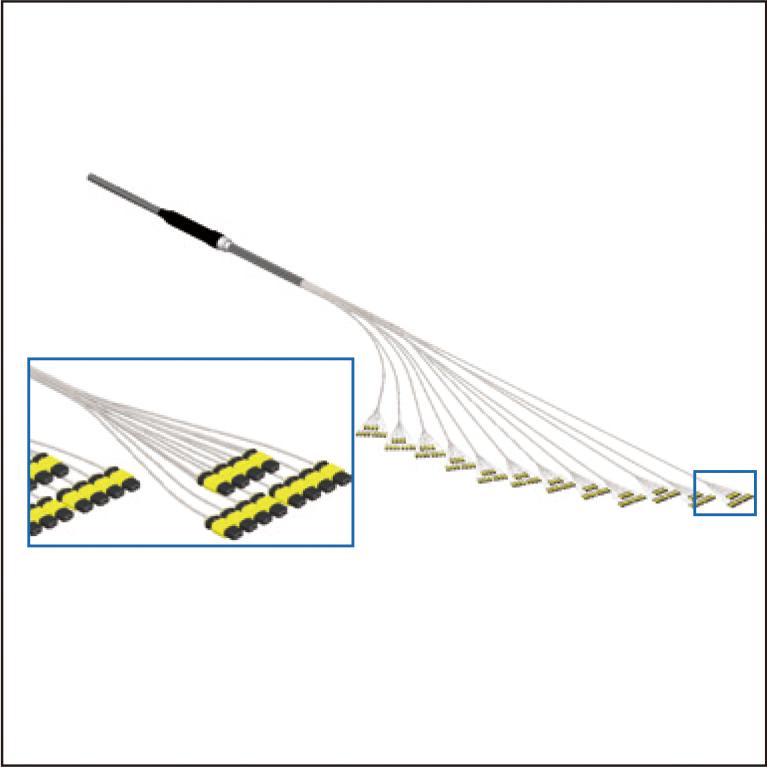

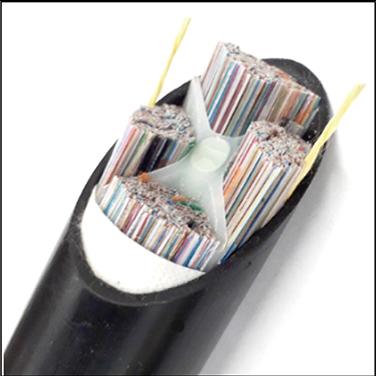

This paper describes the structure, characteristics, and workability of the highly functional small-diameter 6912-fiber-count outdoor/indoor cable (small-diameter 6912-fiber-count O/I cable) designed for Data Center (DC) applications. This cable incorporates the conventional 200 μm fiber with a 12-fiber Freeform Ribbon, and a 16-fiber Freeform Ribbon suitable for parallel transmission used for AI and in DCs. To achieve a smaller diameter, we developed a central tension member (TM)-type spacer cable named “X-treme Spacer Cable.” This structure eliminates the bending directionality, which is also a characteristic of conventional spacer types, while successfully achieving a reduction in diameter and making the most of its excellent installation workability. With a non-preferential bend axis, this cable can easily be installed in space-constrained areas. Additionally, we developed a highly flame-retardant and low-smoke outer jacket material called Low Smoke Zero Halogen (LSZH), which has passed the stringent UL riser fire safety standards in North America. The use of this cable is expected to significantly reduce installation time and costs for DC optical wiring.

5.4 MB

5.4 MB

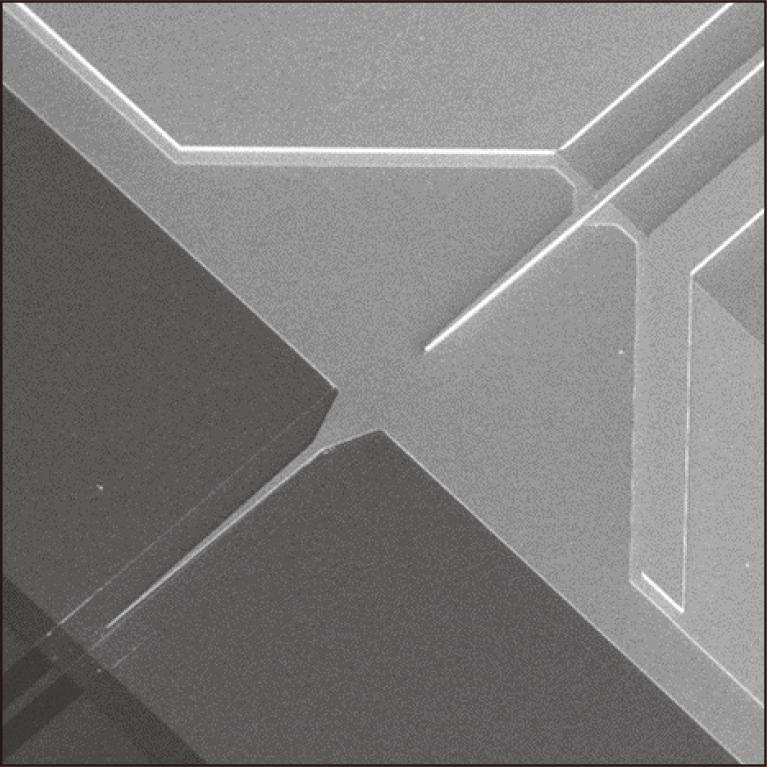

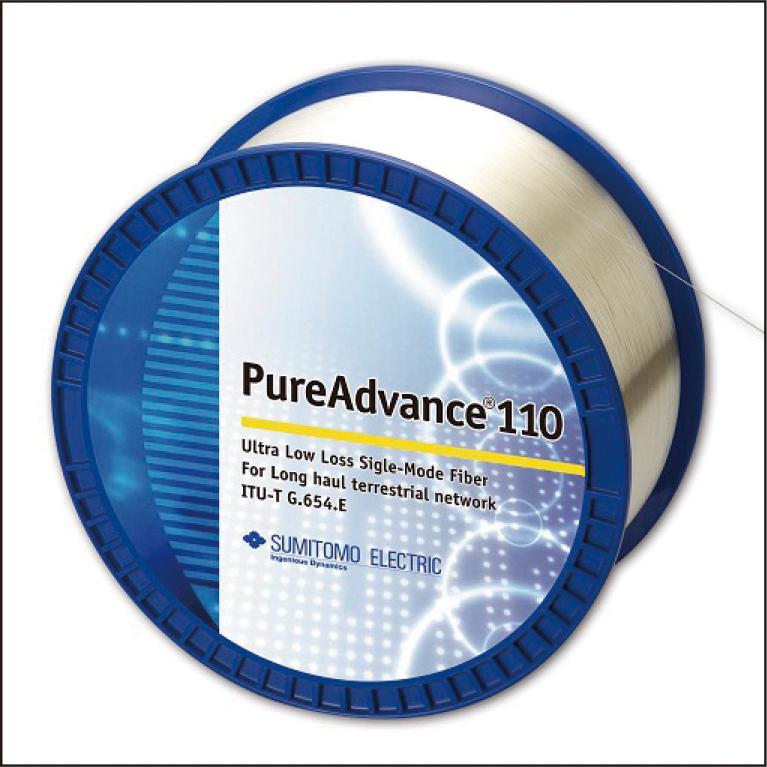

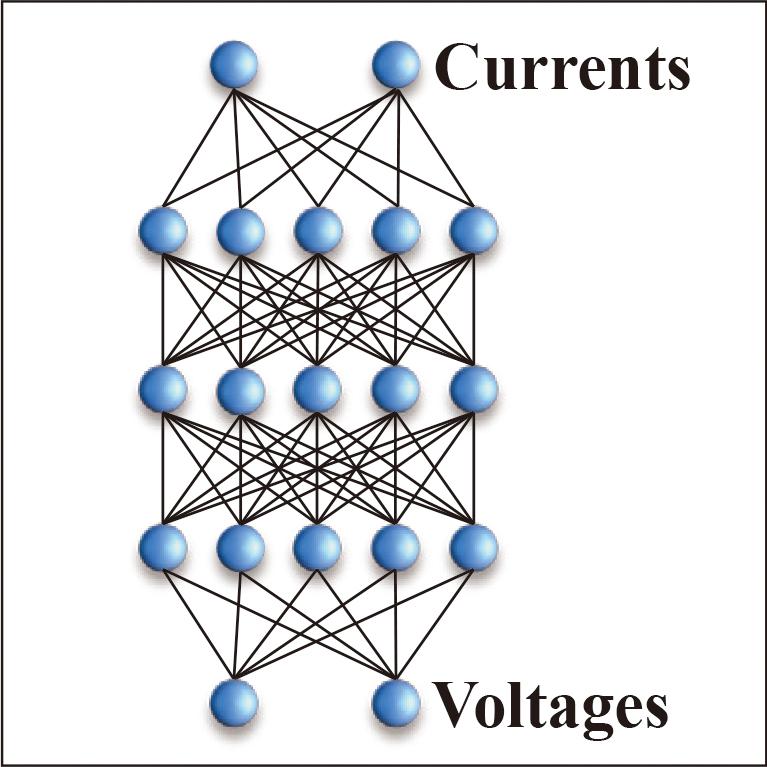

As the utilization of generative AI expands, the volume of information communication within data centers (DCs) is continuously increasing, and demands for long-distance communication such as that between DCs and trunk lines is also on the rise. Coherent optical communication technology is primarily used for this long-distance information communication. In anticipation of the widespread adoption of 800 Gbit/s digital coherent optical communication, we developed a 128 Gbaud optical modulator driver integrated circuit (IC) and a transimpedance amplifier (TIA). These ICs are required to achieve gain peak characteristics and variable gain functionality, in addition to high-speed operation matching the modulation speed of the optical signal. This report presents the IC design techniques and evaluation results necessary to achieve this performance.

2.6 MB

2.6 MB

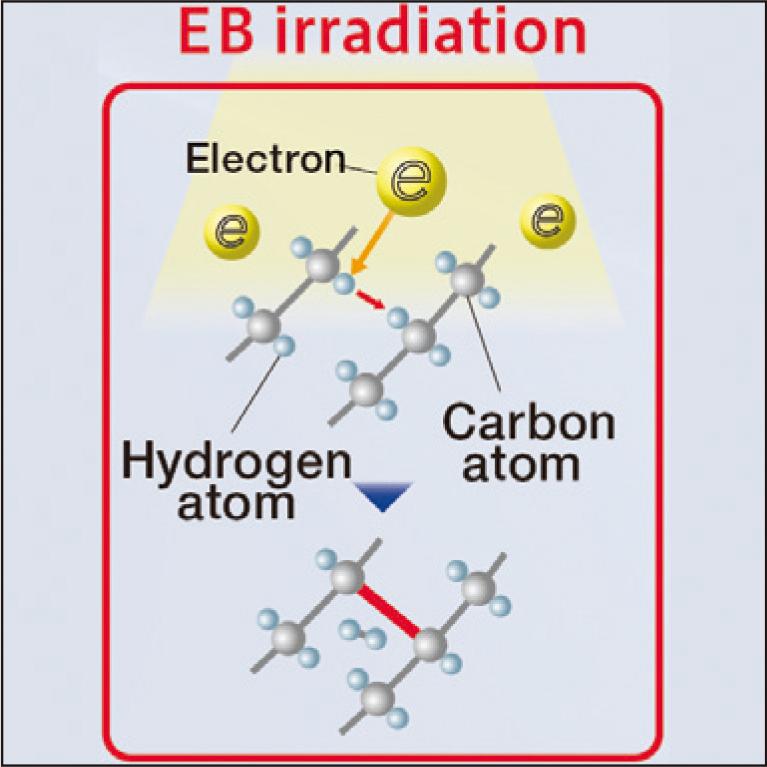

Electron beam irradiation technology has been used in various industrial processes, including enhancing the heat resistance of wire coatings through cross-linking and improving the flowability of rubber sheets for tires. NHV Corporation has supplied numerous electron beam processing systems (EPS) within an extensive energy range of 100 kV to 5 MV to customers globally. In pursuit of the sustainable development goals, there is growing demand for environmental considerations, worker safety, and equipment downsizing. In response, NHV Corporation reports on the development of a new compact EPS (EB-XW) that drastically reduces the use of hazardous lead and enhances maintenance safety.

3.3 MB

3.3 MB

Recently, the introduction of renewable energy such as solar power generation and wind power generation has been progressing in order to achieve carbon neutrality. However, the amount of power generated by renewable energy sources fluctuates depending on weather conditions, so storage battery systems are being used for grid stabilization. In addition, there is a growing need to cut peak power demand in factories, to implement power leveling during the day and night, and to supply power during blackouts. To reward these requirements, Nissin Electric Co., Ltd. has developed a new type of power conditioning system for storage batteries. We introduce these topics in this report.

2.3 MB

2.3 MB

Laser welding is increasingly used across various industries, especially in the automotive sector, due to rising demands for vehicle weight reduction and electrification. It is known that improvements in processing quality, such as reduced spatter, can be achieved by irradiating metal materials with a dual beam consisting of a center beam and a ring beam. While one method to achieve this involves introducing an oscillator capable of outputting dual beams, another method uses a beam-splitting diffractive optical element (DOE). The first approach faces the challenge of high implementation costs, while the second approach faces the challenge of the inability to adjust the intensity ratio of the dual beams, respectively. To address these challenges, Sumitomo Electric Hardmetal Corp. developed the Adjust-Shaper, which retrofits existing single beam systems to enable dual beam output and allows for flexible adjustment of the intensity ratio. This paper presents the product features and evaluation results from its implementation in a laser processing head.

2.3 MB

2.3 MB

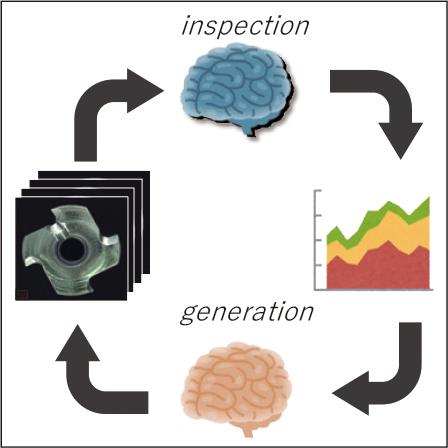

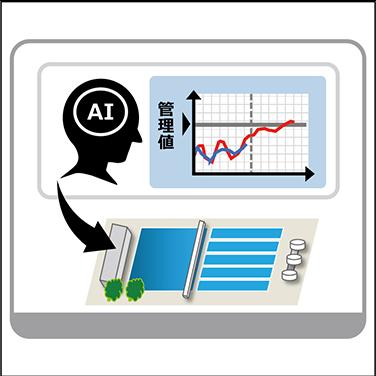

Our company has traditionally relied on manual visual inspections for defect detection, which required considerable manpower and often led to inconsistencies in inspection standards depending on individual inspectors. To address these issues, we developed an AI-based visual inspection system to automate defect detection. However, a key challenge was the limited availability of defective product images for training, which impeded the enhancement of detection accuracy. To resolve this, we introduced an image generation AI capable of producing a large number of synthetic defective images from a small number of real defective samples. Furthermore, we developed a complementary method to analyze and identify the types of images that the inspection AI system is prone to misclassifying, thereby pinpointing its weaknesses. By generating targeted images to address these weaknesses and iteratively training the inspection AI system in a focused manner—a process we term the “anti-weakness training loop"—we were able to significantly improve system performance. Consequently, even with limited real defect data, we shortened the development time and enhanced the detection accuracy of the visual inspection AI system. This paper reports on the development and results of this approach.

2.9 MB

2.9 MB

We are developing and operating AI systems for automated visual inspection of products using image data. Implementing such AI in manufacturing environments presents two main challenges: First, substantial manpower is required to prepare the necessary image data and its accompanying annotations (labeled data) for AI development. Second, the basis of AI inspection results is not visualized, hindering trust in the factory setting. To address the first challenge, we applied self-supervised learning to the Transformer AI architecture, a method also adopted by ChatGPT, minimizing the need for extensive annotations. For the second challenge, we developed a function to incorporate human knowledge into AI by utilizing our novel sigmoid attention mechanisms to clarify the areas of focus. Our original sigmoid attention, adopted as a method of utilizing attention, not only enhances the visualization of the grounds for AI judgments but also contributes to performance improvement. We report our solutions to the two challenges in detail.

2.5 MB

2.5 MB

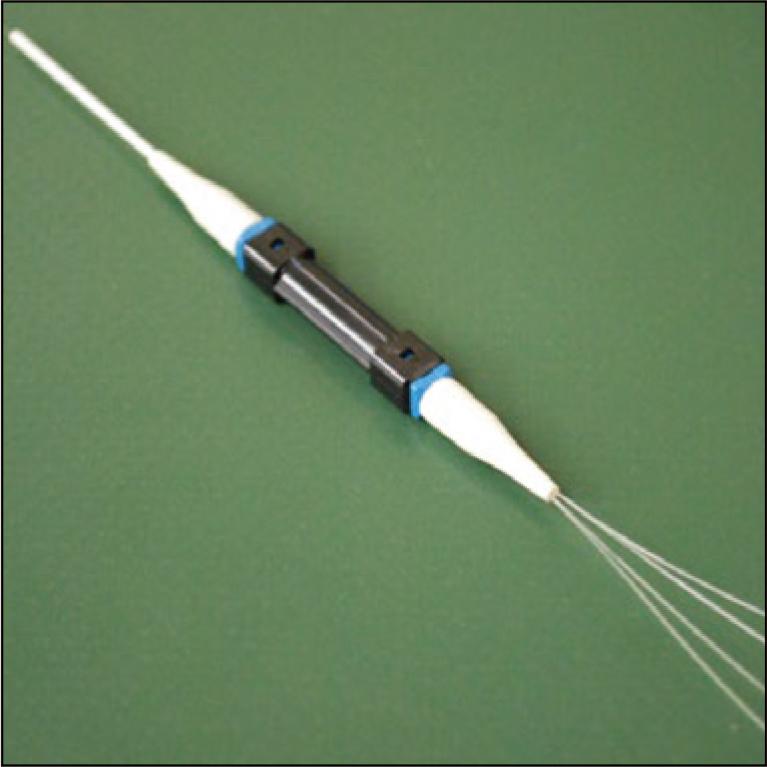

Active optical cable (AOC) are optical harnesses equipped with photodetectors that enable long-distance high-speed transmission of optical signals (e.g., 100 m, 40 Gbps) over multimode fiber. In recent years, there has been increasing attention in the medical and industrial machinery sectors for the replacement of metal wiring with AOCs using optical fibers to suppress electrical noise in high-speed signal transmission paths. However, in certain applications, metal wiring is still necessary for power supply and other needs, making hybrid AOCs that combine metal wires and optical fibers essential. Additionally, with the miniaturization of devices and an increase in moving parts within the same sectors, there has been a growing demand for robust mechanical reliability in wiring materials. Yet, the difference in mechanical reliability between optical fibers and metal wires has become a concern. This report introduces the Unbreakable Active Optical Cable (UB-AOC), developed by enhancing the mechanical reliability of metal wires, which are generally less reliable than optical fibers. We have implemented a specialized resin coating on our proprietary Thick Copper Covered (TCC) wire.

1 MB

Currently, data center (DC) construction is progressing to accommodate the rapid increase in traffic due to the emergence of generative AI and machine learning. By interconnecting multiple DCs, data can be shared, and services such as backup and redundancy can be provided. To realize these services, it is necessary to install optical cables in outdoor underground ducts that connect distant DCs, and there is an expectation that many fibers can be efficiently deployed within these space-limited ducts in a short term. In this context, Sumitomo Electric Lightwave Corporation has commercialized new outdoor/indoor hybrid cables (OI cables) ranging from 288–3,456 fibers by changing the cable design from conventional central tube cable to Monotube Cable, resulting in a drastic reduction in cable outer diameter and weight compared to previous designs.

0.7 MB

In recent years, the use of microwaves for heating applications has been expanding, not only in consumer applications such as food heating in microwave ovens but also in industrial processes including food processing, drying of materials like wood and resins, as well as plasma generation in semiconductor equipment. Traditionally, magnetrons have dominated the field of microwave heating due to their low cost and high output as vacuum tube components. However, Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have garnered attention in recent years due to their long lifespan, high reliability, and low noise characteristics. Additionally, GaN HEMTs offer high controllability of phase, frequency, and output power, enabling the realization of new heating functions such as uniform heating and selective heating.

0.8 MB

Shipboard radar is used for navigation, collision avoidance, and weather monitoring, with operating frequencies varying according to application, including X-band and S-band. In recent years, there has been an expected increase in radar demand due to a growing emphasis on safety aimed at automated navigation. Among this trend, there is a shift from vacuum tube components, such as magnetrons, to solid-state components like Gallium Nitride High Electron Mobility Transistors (GaN HEMTs). This shift is driven by the fact that vacuum tube components have a relatively short replacement cycle of 1 to 2 years due to their limited lifespan, which contributes to rising operational costs. In contrast, solid-state components offer long-term reliability of over 10 years, eliminating the need for regular replacements like those required for magnetrons. Additionally, technologies such as pulse compression enable solid-state components to achieve radar performance equal to or exceeding that of magnetrons with lower power consumption, leading to expectations of continued demand growth.

0.7 MB

At Sumitomo Electric Industries, Ltd., the Industrial Materials Group is only one of five business segments that was organized according to our product category: materials, rather than market. Therefore, it is difficult to find consistency in customers, market, application, and research and development (R&D) direction in each business area. On the other hand, there is a commonness in that each industrial materials division tries to make the materials and their quality unique and thus to differentiate these materials from the products of our competitors. In the development of new materials, the responsible divisions are also common in approaching the R&D projects scientifically and efficiently by employing computational science, machine learning, and other tools, which will be discussed later. At the occasion of the publication of this special issue on industrial materials, I briefly describe the history and future direction of development in each of our businesses with a focus on materials.

1.5 MB

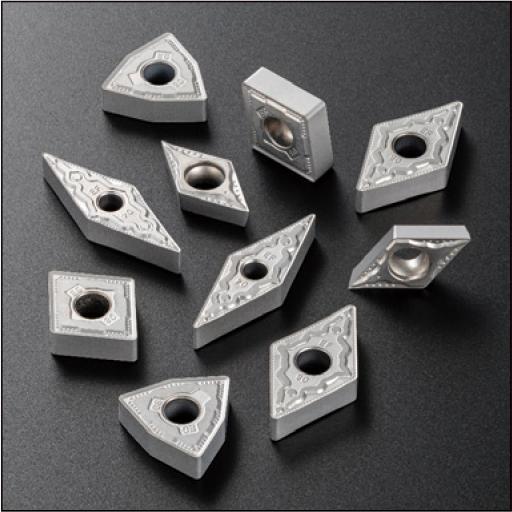

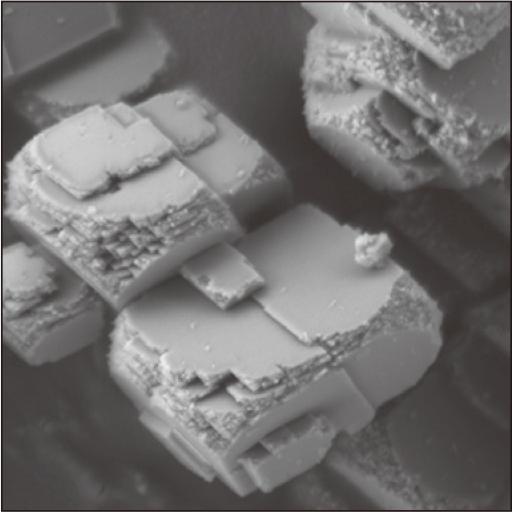

High-strength materials like titanium alloys and heat-resistant alloys are difficult-to-cut materials. They are used in industries such as aerospace and medical sectors, where the demand for high-quality processing and efficiency is increasing. For these demands, we have developed next-generation ultrafine-grained cemented carbide for difficult-to-cut materials. We successfully improved the interface strength between hard-phase particles to prevent damage from particle detachment and reduce wear in high-efficiency machining by enhancing the binder phase strength. By integrating these two technologies, we have achieved longer tool life in cutting difficult-to-cut materials. At the occasion of the publication of this special issue on industrial materials, I briefly describe the history and future direction of development in each of our businesses with a focus on materials.

6.3 MB

6.3 MB

During cutting processes, cutting edges cannot be directly observed, leading to reliance on skilled workers' intuition and experience for optimizing cutting conditions. In recent years, sensors equipped in machine tools have been utilized to comprehensively monitor machining conditions including cutting forces. However, their sensitivity and accuracy are insufficient due to distance between the cutting point and measurement position. To address this challenge, we have developed “Sumi Force,” a sensing tool that measures cutting forces in real-time by embedding strain sensors in the tool holder, where inserts, drills, or end mills are held, closest to the cutting point. The measured data is wirelessly transmitted outside the machine tool, enabling easy integration to various machines and production lines used by customers. This paper introduces a new solution service that utilizes “Sumi Force” to optimize machining processes for customers, and discusses the development of techniques to detect anomalies such as tool wear and breakage based on changes in cutting force.

3.8 MB

3.8 MB

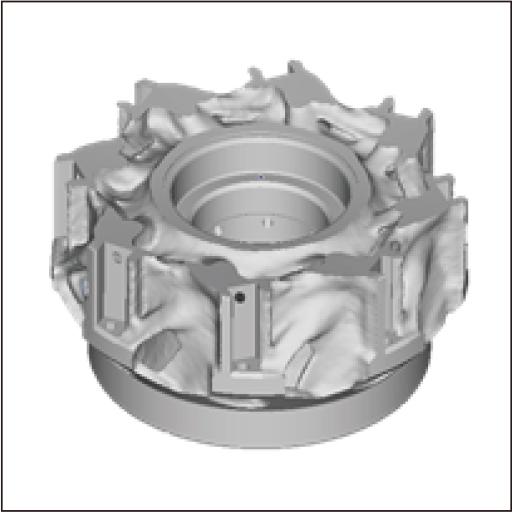

Cutting tool requirements change from year to year. In the automotive industry, the shift to electrification is increasing the demand for lightweight tools that enable highly efficient machining of aluminum alloy components. In the aerospace industry, the use of difficult-to-machine materials such as nickel-based alloys and titanium alloys to reduce engine noise and fuel consumption is increasing, as is the need for through-coolant tools that can efficiently cool cutting edges when machining these materials. In response to these shifting market demands, we are employing additive manufacturing (AM) to develop innovative cutting tools. This time, by utilizing AM to form a complex internal structure, we have realized a lightweight cutter for aluminum machining that maintains the rigidity of the cutting edge while reducing the weight. Additionally, we have developed a cutter for difficult-to-cut materials that enables uniform cooling of the entire cutting edge by optimizing the internal flow path.

6.2 MB

6.2 MB

In recent years, various industries, including the automotive sector, have been advancing their initiatives toward achieving green transformation (GX) by reducing CO2 emissions in cutting processes. Decreasing CO2 emissions involves cutting machine power consumption, leading to a rising demand for high-efficiency machining tools that reduce machine cycle time. To meet these requirements, we have developed the MULTIDRILL MDA Series for aluminum drilling and the MULTIDRILL MDH Series for steel and cast iron drilling. The MDA series enables high-precision, high-efficiency aluminum machining, while the MDH series delivers high-efficiency machining with reduced cutting force and power consumption for steel and cast iron processing. These tools contribute to power-saving in hole making processes.

6.1 MB

6.1 MB

Efforts are underway in the steel machining, particularly in the automotive industry, to reduce the environmental impact and to enhance resource efficiency. We introduced the AC8000P series for steel turning in 2016, featuring the new chemical vapor deposition (CVD) coating technology “Absotech,” and have since expanded our product range. In recent years, there has been a growing trend in steel turning especially toward reducing machining time and transitioning to dry cutting without the use of cutting fluids. In response to this trend, we have developed AC8115P, a new steel turning carbide grade designed for high-efficiency and dry cutting applications. AC8115P demonstrates outstanding performance by addressing the challenges of high cutting-edge temperatures, effectively minimizing tool wear and plastic deformation. This grade’s enhanced resistance characteristics are key to reducing machining costs and environmental impact in steel turning operations.

7 MB

7 MB

Titanium alloys are widely used for equipment and parts in the aerospace industry due to their lightweight, high strength and excellent corrosion resistance. Additionally, these alloys are also used in the medical field because of their high biocompatibility. In recent years, both industries have experienced significant growth, leading to a marked increase in demand for cutting tools for these alloys. However, when machined, titanium alloys are prone to adhesion due to chemical reactions with tools and heavy wear resulting from low thermal conductivity, leading to a significant reduction in cutting tool life. Thus, the demand for cutting tools with stable performance and a long tool life has been increasing. The newly developed "AC9115T" and “AC9125T” are designed to improve wear resistance by applying a new physical vapor deposition (PVD) coating. These coated carbide grades help reduce the frequency of cutting edge replacement and tool consumption by extending the tool life, contributing to the reduction of machining costs.

7.9 MB

7.9 MB

The cubic boron nitride (CBN) cutting tool “SUMIBORON” is made of sintered cBN particles, which have high hardness and thermal conductivity next to diamond and low reactivity with ferrous metals, bonded with a metal and/or ceramic binder. It has contributed to the improvement of machining efficiency and cost reduction in processing hard-to-cut hardened steel, and in machining of cast iron and sintered alloy where high-precision machining is required. In recent years, the machining of cast iron and sintered alloy parts—key components in automotive and construction machinery—has seen increasing demand for stability, long tool life, and high efficiency. In addition to high dimensional accuracy and surface quality, there is also a growing need for manpower savings in production lines and the manufacturing of high-precision parts. In response to the demand, we have developed CBN cutting tools SUMIBORON BN7115 and BN7125. BN7115 is designed for finishing, offering improved chipping resistance for stable, high-quality surface machining, while BN7125 is designed for general-purpose use, with enhanced breakage resistance for stable, long tool life even under heavy cutting loads. This report describes the features and performance of BN7115 and BN7125.

2.7 MB

2.7 MB

SUMIBORON is a cutting tool that utilizes cubic boron nitride (CBN) sintered bodies formed from cBN particles and ceramic or metal bonding materials. Specifically, coated SUMIBORON has an expanded application range as a cutting tool for hardened steel in automotive parts. Recently, manufacturing sites have become aware of variable-volume production due to the diversification of parts and the importance of environmental considerations. Two trends have emerged: reducing CO2 emissions by lowering equipment power consumption and establishing automated product lines to address price competition. Cutting tools require higher efficiency and longer tool life. To meet customer requests, we developed four new grades in the BNC2100 series: BNC2105, BNC2115, BNC2125, and BNC2135.

2.8 MB

2.8 MB

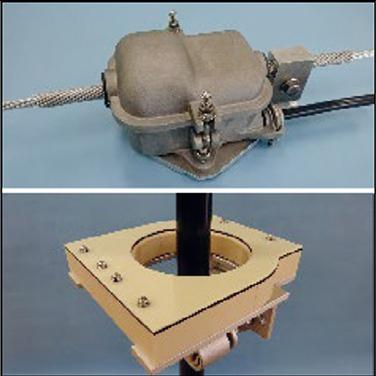

The tensioning process of prestressing steel strands involves introducing the required prestressing force into concrete structures, which is a critical step affecting the structure's durability. Traditionally, this process involved manual operation of tensioning equipment for prestressing steel strands and visual readings of analog gauges for recording, leading to challenges such as labor-intensive processes, measurement errors, and the need for proximity to tensioning equipment. The automatic tension control system automates these tasks using control devices and digital measuring instruments, contributing to reduced manual labor, enhanced accuracy, and improved safety. This paper provides an overview of the wireless automatic tension control system that eliminates the need for communication cable wiring, along with examples of its application and benefits.

5.6 MB

5.6 MB

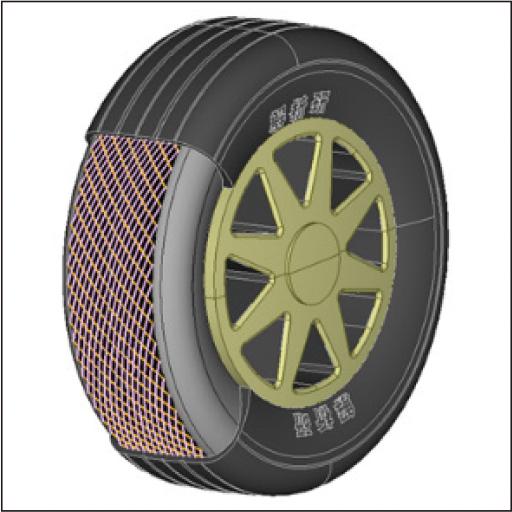

Steel cords, used as reinforcement in rubber products, are essential components for automotive tires that require high standards of fuel efficiency, durability, handling stability, and noise reduction. Conventionally, the development process involved repeated experiments, evaluations, and modifications to ensure the steel cords meet the required tire performance levels. However, this approach posed challenges such as extended development periods due to the time and effort required for evaluations, difficulties in achieving sustainable society due to tire waste, and the influence of tire design factors on tire performance. To address these issues, we developed a performance prediction technology that incorporates steel cord features. This technology enables efficient and accurate examination, specification refinement, and narrowing-down and evaluation of technical interpretation in tire design involving steel cords. The technology not only enhances tire performance but also contributes to achieving the Sustainable Development Goals, earning high praise from our customers.

3 MB

3 MB

We assessed the application of high-strength steel wires (spring wires) for creating safe and efficient blades for grass cutters. Utilizing our specially shaped wires, blades were produced and tested in the fields of the National Agriculture and Food Research Organization (NARO) using both grass trimmers and remote-controlled grass mower. By changing the steel wire's cross-sectional shape from a simple square to a pentagon with sharp apexes, we achieved cutting performance comparable to traditional chip saws. The remote-controlled grass mower successfully showed its performance in cutting down bushes and woody plants with diameters over 10 mm, which was impossible with nylon cords. Introducing a freely rotating attachment for the cutting blade prevented fatigue failure of the steel wire blade and eliminated the risk of “kickbacks.” However, during stone skipping tests, significant stone scattering occurred, and the attachment part showed weakness in impact resistance against hard objects, prompting us to propose solutions for these challenges.

9.4 MB

9.4 MB

To achieve carbon neutrality, it is necessary to reduce CO2 emissions and increase the amount of CO2 absorption simultaneously. One method to increase CO2 absorption is through carbon recycling, which involves the production of functional materials and iron carbonate (trademark: metacol), using iron and CO2, which have an affinity with our manufacturing sites. This paper reports on this method. We aim to utilize iron carbonate in our own products, incorporating the emitted CO2 into material circulation and continuously isolating it from the atmosphere. Through principle verification, functional evaluation, equipment design, factory verification, and intellectual property protection, we will proceed to validate customer value. We will confirm achieving a negative CO2 balance and profitability, and aim to contribute to carbon neutrality through carbon recycling.

1.2 MB

1.2 MB

Iron-based sintered parts have traditionally been used as structural components across various fields due to their ability to be efficiently net-shaped into complex shapes using powder compacting technology, leveraging the excellent balance of strength and cost that iron offers. In recent years, the demand for smaller, lighter, high-strength, non-magnetic materials has been on the rise in sensing technology required for further advancements like electric vehicles, high-performance appliances, and smart factories. In response to these trends, we have developed a new non-magnetic, high-strength iron-based sintered material that goes beyond existing materials. This paper discusses the characteristics and benefits of this newly developed material.

1.7 MB

1.7 MB

We have developed soft magnetic composites (SMCs) and an axial flux machine (AFM) utilizing SMCs to contribute to the advancement of a sustainable society. The estimated CO2 emissions from SMC manufacturing are approximately one-quarter of those produced during magnetic steel sheet manufacturing. Additionally, we have developed a recycling technology that allows for the reuse of powdered motor stator as raw material for SMCs while demonstrating consistent magnetic properties before and after recycling. Furthermore, our innovative design of a 75 kW-class AFM with a power density of 12.6 kW/kg illustrates the effectiveness of SMCs and AFM in reducing material usage. Finally, we have confirmed that our 20 kW-class AFM, which incorporates low CO2 emission ferrite magnets, matches the size, power, and efficiency of a radial flux machine utilizing Nd sintering magnets.

4.7 MB

4.7 MB

Powder metallurgy involves compressing powder in a mold and sintering it to strengthen compact parts. Through innovative mold designs, near-net-shape compacts that closely resemble the final product can be achieved. Parking support parts are found in various vehicle types, including hybrids and electric cars as well as gasoline cars, and are crucial components used in parking lock systems to prevent wheel rotation during parking, with diverse shapes. We successfully developed parking support parts utilizing the shape flexibility of powder metallurgy, contributing to the growth of the sintering market. Our development includes examples like adjusting density balance by removing excess powder, compacting two different shapes, creating horizontal grooves, and integrating multiple components. Additionally, the use of partial laser hardening has enabled precise production while promoting environmentally friendly manufacturing practices.

2.2 MB

2.2 MB

Research on fusion energy, a key contender for achieving decarbonization, is becoming increasingly active. Tungsten (W) is used in the divertor of fusion reactors, which is exposed to extreme temperatures exceeding 2000°C. The DEMO-Reactor, designed to demonstrate power generation, is expected to operate for extended periods, requiring increased mechanical durability from W materials used in fusion reactors. In collaboration with universities and other institutions, A.L.M.T Corp. has evaluated various materials and has found the effectiveness of potassium (K)-doped W. Aiming to apply the findings to plasma-facing components, we have developed K-doped W thick plates tailored for this specific application. This paper reports the evaluation results of the main characteristics of these materials.

3.3 MB

3.3 MB

Sumitomo Riko Company Limited has successfully developed a water-soluble coating material with a high filling of "silica aerogel," a highly insulating material, and created a thin film high insulation material. This material has the highest level of insulation performance through air insulation and can exhibit its performance even when the thickness is 1 mm or less. In recent years, there has been a growing trend of increasing heat generation density in electronic devices and batteries due to their high integration and miniaturization. Therefore, we are considering applying this material to contribute to thermal management. Additionally, it is attracting attention as a product that can enhance the thermal efficiency of factory facilities and contribute to the reduction of energy consumption such as fuel and electricity, thanks to its easy application. It has already been adopted in the manufacturing industry.

2.8 MB

2.8 MB

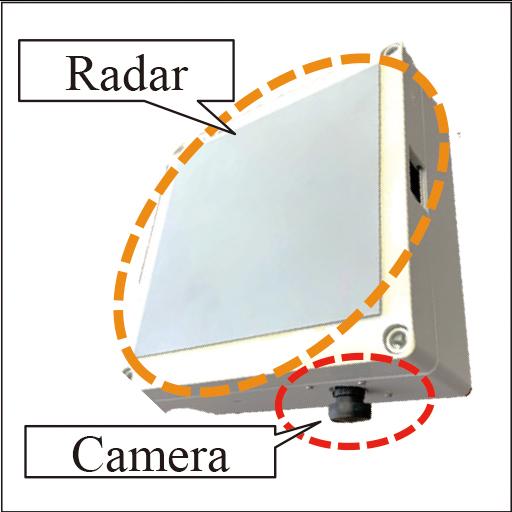

In the U.S., the increase in pedestrian fatalities has led to a rising demand for pedestrian detection sensors in systems aimed at preventing traffic accidents. However, many existing sensors lack sufficient vertical detection range since they are typically installed at high positions in actual intersections, creating blind spots directly below them. In cases where the installation point is adjacent to a pedestrian crossing, there are instances where parts of the crosswalk or waiting area may go undetected. To address this issue, we have prototyped a fusion sensor combining radar with a camera. The fusion sensor eliminates blind spots below it by detecting pedestrians at the spots with the camera. Furthermore, using object recognition AI with camera images enables the sensor to identify the type of detection targets, a challenge for radar alone. This paper introduces the prototyped fusion sensor configuration and presents the results of performance verification experiments.

7.3 MB

7.3 MB

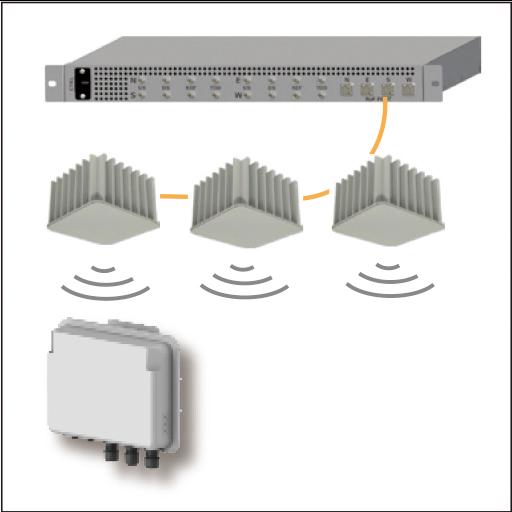

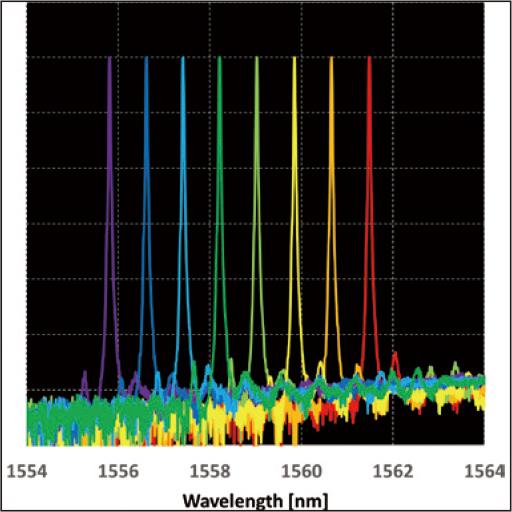

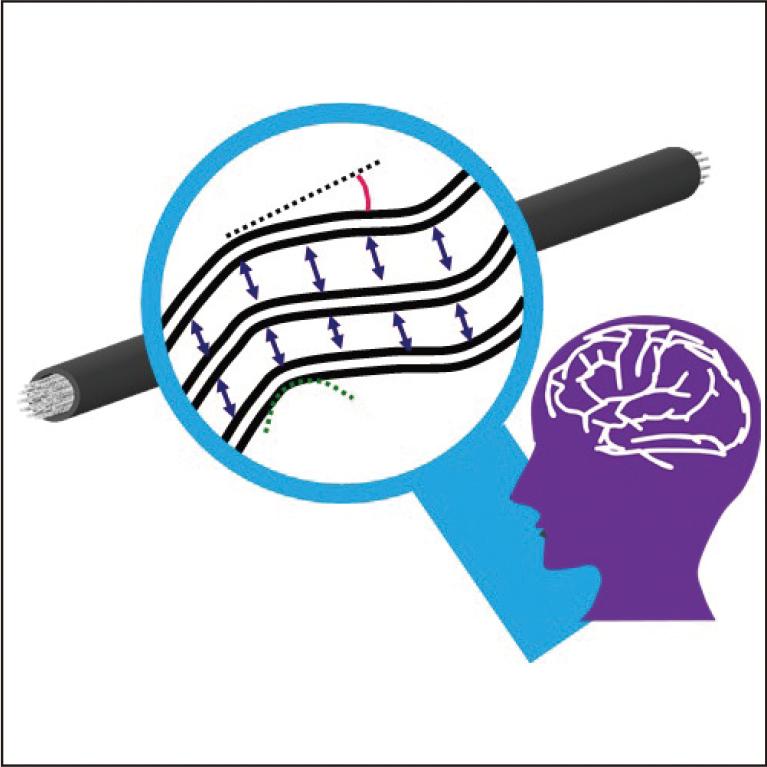

Our company is developing Analog Radio-over-Fiber (A-RoF) technology for wireless signal transmission, enabling the transmission of radio waves through optical fiber while maintaining their waveform for 5G and 6G wireless communication. This paper introduces our efforts in developing A-RoF technology, focusing on enabling the economically viable deployment of millimeter-wave (mmWave) radio communication systems , which are essential for broadband wireless communication in the eras of 5G and 6G. Additionally, we showcase the application of A-RoF technology in the 5G millimeter-wave distributed antenna system (DAS) and industrial 5G terminals supporting millimeter-wave communications.

2.1 MB

2.1 MB

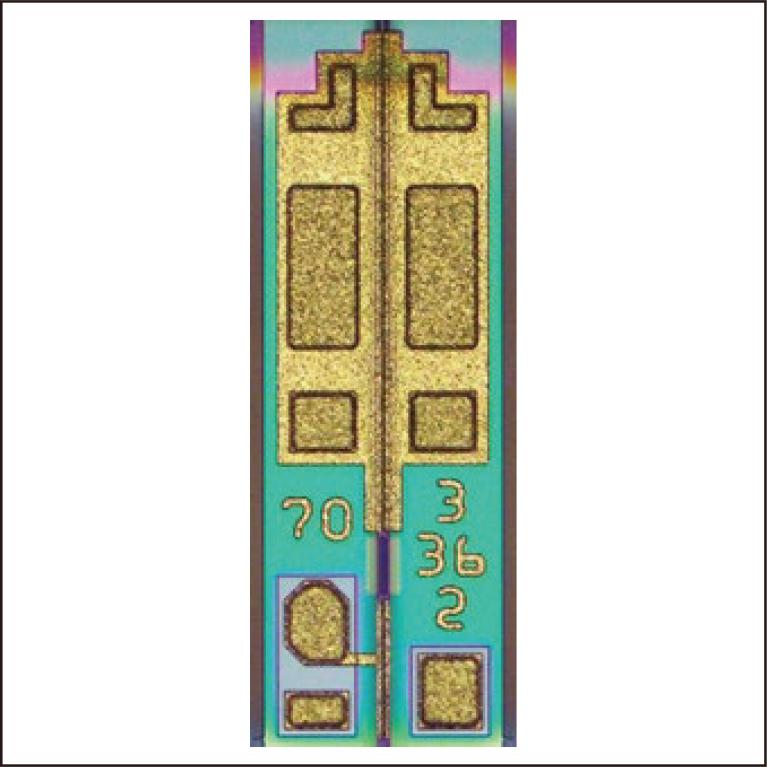

Nisshin Ion Equipment Co., Ltd. has pioneered the development of “KYOKA,” the world's first mass-production material modification equipment for semiconductor device manufacturing. By combining our high-current large-area ion source technology with advancements in low-energy ion beam transport efficiency and the development of stable metal ion sources, we have successfully developed this innovative equipment. The use of this equipment is expected to advance semiconductor microfabrication technology and enhance device performance. This paper provides an overview of the demand for material modification, the structure and features of the equipment, and presents experimental results utilizing the equipment.

1.2 MB

1.2 MB

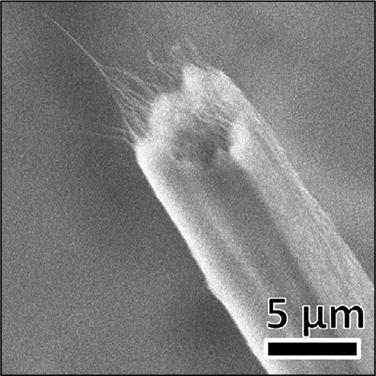

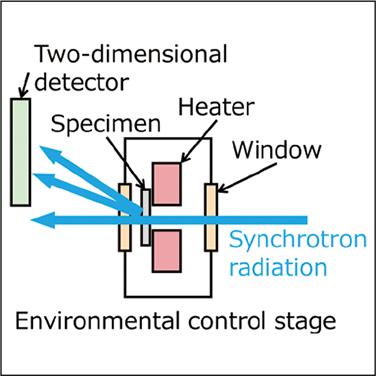

Fluoropolymers have excellent properties such as heat resistance, chemical resistance, and low friction. However, their susceptibility to wear has been a significant drawback. The cross-linked fluoropolymer FEX, developed using electron beam crosslinking technology, has significantly enhanced wear resistance and paved the way for its use as a sliding material. In the past, application to general molded products was challenging due to the requirement for electron beam irradiation in a molten state exceeding the resin's melting point, causing to deformation of the molded shape. This paper presents recent insights into the utilization of FEX technology for such molded applications.

4.2 MB

4.2 MB

Evaluating the performance of electric cable products under external forces, such as bending, is crucial for assessing their behavior in real-world environments. We utilize a cutting-edge X-ray computed tomography (XCT) system to observe the effects of external forces and employ various data analysis techniques to enhance our understanding of how cable products respond dynamically to these forces. The first part of this paper introduces XCT observation results of some samples, including a bent cable and a large 1-meter sample, which were previously difficult to evaluate with former XCT systems. The latter part focuses on image analysis techniques for bent cable products, highlighting our unique technology. Through a combination of advancements in hardware and software, we can improve design processes and solve quality issues by clarifying the dynamic behavior of various cable products under external forces.

3.5 MB

3.5 MB

For the first time for a local power utility established by a municipality, a redox flow battery system was delivered to Kashiwazaki Ideal & Realistic Energy Co., Ltd. located in Kashiwazaki City, Niigata Prefecture. As the introduction of renewable energy expands, it is expected that the introduction of long-duration energy storage (LDES) with a capacity of 6 hours or more will accelerate in the future. This installation is an example of an LDES connected directly to the power grid.

1.5 MB

In the firing process of magnets, ceramics, and other materials, many setter plates for firing, which are manufactured from molybdenum plates and rods, as well as heaters and reflectors for high-temperature furnaces are used. To improve the quality of fired products, there is an increasing demand for molybdenum mesh (mesh material) for venting during firing and preventing the sticking of the setter plate to the fired products. This mesh material is fabricated using wires of 0.5 mm or less in diameter. This paper introduces “mesh with edge folded” and “mesh with improved resistance to breakage,” both designed to address the problems of “fraying” and “breakage due to high-temperature use” observed in practical applications, as along with standard molybdenum mesh.

1.3 MB

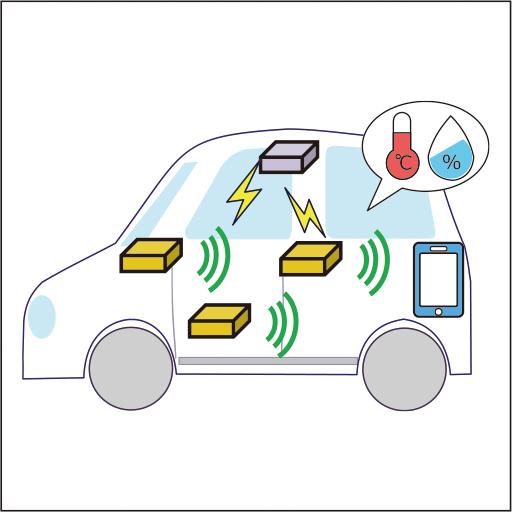

With the advancement of autonomous driving and vehicle electrification, the number of onboard sensors is expected to increase. Powering each sensor via wired connections can lead to increased costs and weight due to power and communication cables. This paper investigates wireless power transmission using a spatial transmission method to supply power to each sensor. We confirmed that a temperature sensor embedded in the headrest could operate at 30-second intervals using wireless power transmission at a transmission frequency of 920 MHz and a transmission power of 1W. In addition, we simulated the distribution of electric field intensity inside the vehicle cabin and confirmed that the electric field intensity required for the sensor to operate could be achieved in most areas of the cabin.

3.4 MB

3.4 MB

For the realization of autonomous driving, 5G is expected to be used due to its superior features such as high speed, large capacity, and low latency capabilities. To enable large-scale data communication, such as sensing information transmission, it is desirable to use the millimeter-wave band, which has a bandwidth of several hundred megahertz in 5G. 5G millimeter-wave antennas use beamforming technology to transmit radio waves over long distances. We set up a scenario where a vehicle equipped with a 5G millimeter-wave antenna communications with a base station and performs beamforming control while driving, and dynamically evaluated it using 5G signals. This paper reports the evaluation method and results based on the proposed scenario.

3.9 MB

3.9 MB

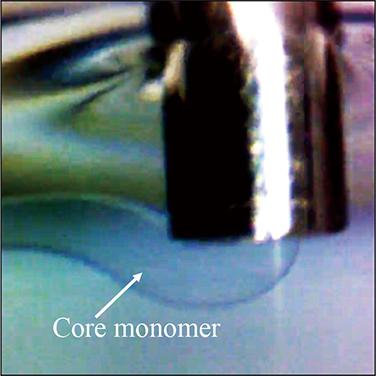

The long-term reliability of optical fibers heavily depends on the durability of the protective coating layers surrounding the glass fiber. The physical properties of the inner layer coating, such as Young's modulus and gel fraction are crucial to the durability. Ultraviolet light (UV) curable resins are commonly used for coating, and accurate prediction of the physical properties under different irradiation condition is essential for optimizing the manufacturing process. However, the complex reaction mechanism involved in UV irradiation-induced radical polymerization poses challenges in accurately modeling these properties. In this study, we presents an analytical formula based on chemical reaction kinetics to determine the concentration of photoinitiators. Moreover, we successfully predict coating properties by utilizing a calibration curve that compares the photoinitiator consumption rate with the coating properties after the curing process.

1.7 MB

1.7 MB

To meet the rapidly increasing demand for optical communication traffic, a high-capacity solution is required through the high-density integration of optical devices. The challenge lies in the potential degradation of device performance due to heat generation. Consequently, there is a need for a semiconductor laser exhibiting superior temperature attributes. Addressing this, we have developed a 1.3 µm-wavelength laser, employing a GaInAs/GaAsSb/GaInAs type-II active layer on a GaAs substrate, suitable for optical communication. This has been achieved utilizing our proprietary low-temperature growth technology from highly productive Organic-Metal Vapor Phase Epitaxy. Our solution exhibits a characteristic temperature of the threshold current density of 152 K between 25°C and 100°C, a value significantly larger than the traditional 60 K of InGaAsP lasers on InP substrates. This result demonstrates the feasibility of a 1.3 µm semiconductor laser with a type-II active layer, less susceptible to performance degradation in high-temperature environments.

1.4 MB

1.4 MB

The growing demand for generative AI and high-performance computing has increased the importance of high-speed, energy-efficient communications in data centers, leading to an increased focus on co-packaged optics (CPO). The external laser sources (ELSs), a component of CPO, require high optical output power of several hundred mW and low power consumption with power conversion efficiency greater than 20%. This paper discusses the integration of a wide stripe waveguide semiconductor optical amplifier (SOA) into a 1.3 μm high-power semiconductor laser for CPO. By using an electrically isolated structure for each element, we have optimized the power distribution to achieve over 400 mW output power and 25% power conversion efficiency at a temperature of 45℃.

1.6 MB

1.6 MB

This paper presents our development of an 8-wavelength tunable electro-absorption modulator integrated laser, designed for mobile and access networks. The laser was created in response to the increased data traffic and data rate demands within 5G mobile fronthaul communication networks, particularly in areas with limited fiber infrastructure. This solution addresses the growing need for wavelength tunable optical transceivers and supports the adoption of wavelength division multiplexing. The performance of the laser was evaluated in a compact 25 Gbit/s dense wavelength division multiplexing (DWDM) transceiver, housed in an SFP28 form-factor.

1.8 MB

1.8 MB

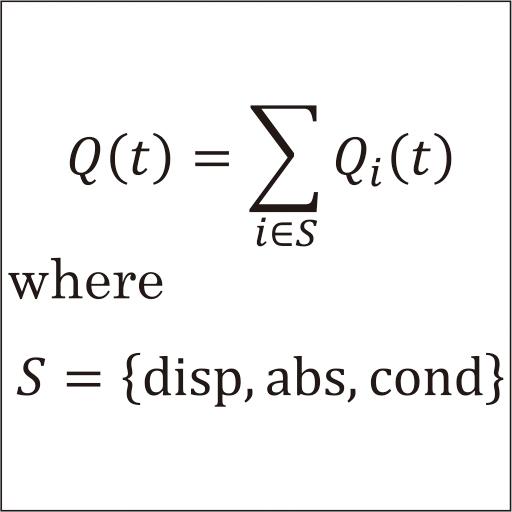

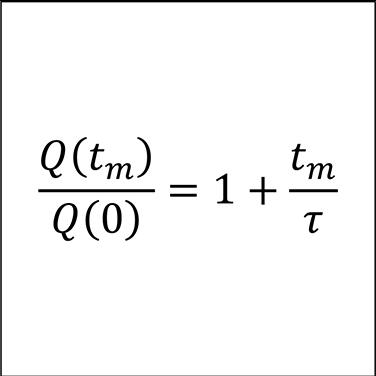

This paper focuses on the “Current Integration Method (Q-t method),” widely used in Japan in recent years, to understand the electrical conduction and space charge behavior of insulating materials, in conjunction with the advancement of high voltage direct current (HVDC) technology and polymer insulation technology. The Q-t method involves connecting an integrating capacitor to the sample in series and measuring the integrated small currents passing through it. The advantage of this method is that it allows comprehensive and panoramic observation of electrical phenomena, and by applying this advantage to dielectric measurements, it enables a wide range of applications such as condition monitoring, understanding the limits of insulation material usage, material selection and evaluation. This paper provides examples of its applications and highlights its unique advantages and functionality.

1.7 MB

1.7 MB

The Nissin Electric Group has been enhancing manufacturing capabilities and improving productivity as part of its medium-to-long-term business plan VISION2025. Our main goal is to improve productivity by strengthening our manufacturing technology. Under the slogan “NISSIN ISSIN” (i.e., Nissin renewal), we have been promoting the smartification of our factories through activities that spin the dual wheels of expanding and inheriting important artisan skills and techniques, while also advancing projects that focus on NPS efficiency and the use of cutting-edge technologies. This paper presents an overview of these efforts.

4.4 MB

4.4 MB

Nissin Electric Co., Ltd.'s equipment and parts solution business utilizes Nissin Electric Group's power equipment manufacturing technology for the contract manufacturing of equipment parts for various industries. Established in 2000 at Nissin Electric (Thailand) Co., Ltd. (NET), this business has expanded its manufacturing bases to Vietnam and Myanmar, supplying equipment and parts worldwide. Since its foundation, Nissin Electric has consistently improved its manufacturing capabilities. This paper describes the manufacturing technology used in the equipment and parts solution business.

2 MB

2 MB

Automotive components have complex designs and thin walls, for weight reduction. In recent years, such materials are becoming increasingly difficult to cut due to their high strength. Meanwhile, there has been a growing demand for high-speed and high-efficiency machining to reduce lead time. Under these circumstances, customers need cutting tools that have long tool life and stable cutting performance. To satisfy these demands, we have developed the new coated grade AC4125K for cast iron turning. This paper describes the features and cutting performance of AC4125K.

4.7 MB

4.7 MB

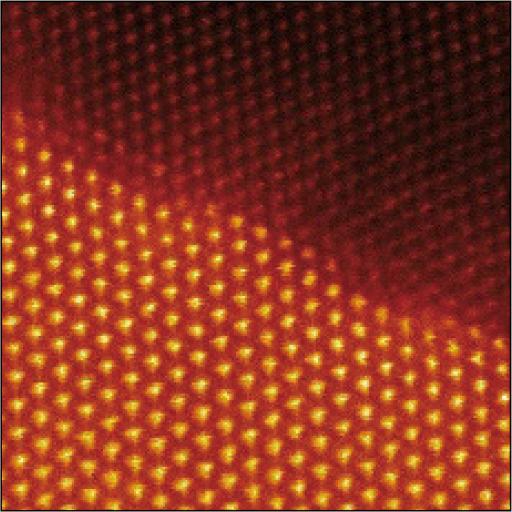

Scanning transmission electron microscopy (STEM), characterized by its high spatial resolution, is a indispensable tool for atomic-level structural analysis of crystalline materials. Particularly in polycrystalline materials such as metals and ceramics, grain boundaries often determine material properties. However, due to the randomness of grain orientations, efficient extraction of grain pairs for grain boundary analysis has been a challenge. In response, we have developed a new technique for crystal orientation analysis using electron backscatter diffraction (EBSD). By applying two types of EBSD methods, reflective and transmission, to sintered tungsten carbide (WC) and cobalt (Co), we confirmed that transmission EBSD can find suitable grain pairs with practical throughput. In addition, STEM analysis successfully detected step structures and Co segregation at WC grain boundaries. The integration of STEM and EBSD analysis developed in this study presents a highly effective approach to structural analysis of polycrystalline grain boundaries for material property improvement.

4.8 MB

4.8 MB

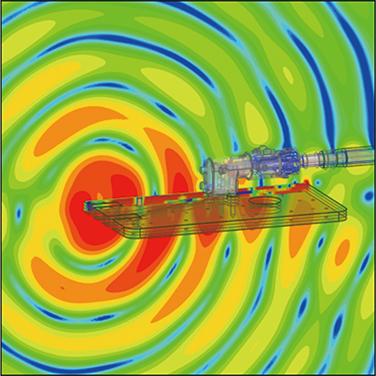

In recent years, technological developments have increased the demand for high-performance radar. Electron tubes and low-power, low-frequency semiconductor elements have been used in the past, but gallium nitride high-electron-mobility transistors (GaN HEMTs), which are optimized for high power and high frequency, are being adopted to increase radar detection range and improve accuracy.

1.1 MB

Cemented carbide, a hard alloy primarily composed of tungsten carbide powder (hereinafter referred to as “WC powder”), is widely used in various fields such as the automotive, aerospace, and electronics industries, due to its high hardness and wear resistance, which can reduce processing costs and time when used as cutting tools. With the increasing demand for multi-functional and high-performance components in recent times, there is a growing need for high-precision tools, prompting the demand for cemented carbides made from fine-particle WC powder that can achieve sharp shapes.

1.2 MB

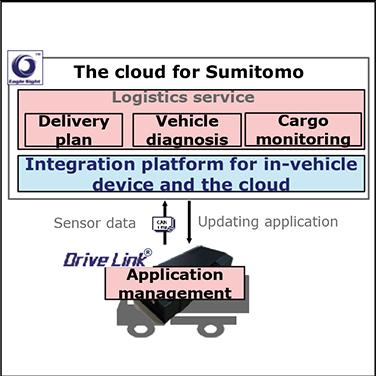

The automotive business of Sumitomo Electric Industries, Ltd. has grown over a long period of time focusing on wiring harnesses . Meanwhile, the automotive industry has been facing the challenge of a once-in-a-century revolutionary transition known as CASE (connected, autonomous, shared, and electric) innovation. The transition is not expected to be limited simply to introducing these elements of connection, automation, sharing/service, and electrification. It has the potential to change the position of cars in society and considerably transform the structure of the automotive industry.

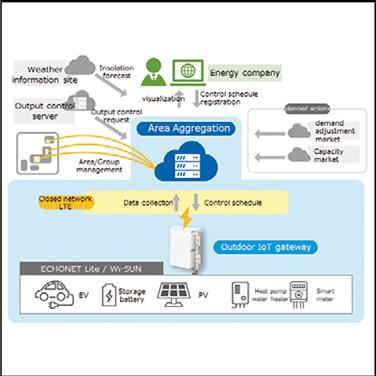

1.3 MB

The automotive industry is currently undergoing a once-in-a-century transformation, with the global adoption of electric vehicles (EVs) playing a significant role in reducing CO2 emissions and mitigating global warming. Alongside, there is a growing need to manage power generation and load fluctuations in the power system that accompany the widespread implementation of renewable energy. In response, the Sumitomo Electric Group has made valuable contributions to society by introducing Traffic Vision Green, a mobility service product that supports comfortable EV driving, and sEMSA, an energy service product that generates optimal operation plans for distributed power sources. Looking ahead, we envision the development of efficient and cost-effective energy management systems (EMS) that consider EV operating conditions by integrating mobility and energy. This paper highlights Sumitomo Electric Group's past accomplishments and outlines our future initiatives for integrated energy management systems that merge mobility and energy sectors.

2 MB

2 MB

With a commitment to environmental sustainability and carbon neutrality, electrification of mobility is progressing significantly. The Sumitomo Electric Group develops and provides a wide range of key technologies and products related to electrification, with “connecting materials/technologies” as our core focus. This paper offers a comprehensive overview of our diverse portfolio, which encompasses four distinct categories: Battery Peripheral, Motor/Inverter Peripheral, High-Voltage Interconnection Wiring/Connectors, and Charging/Infrastructure.

3.2 MB

3.2 MB

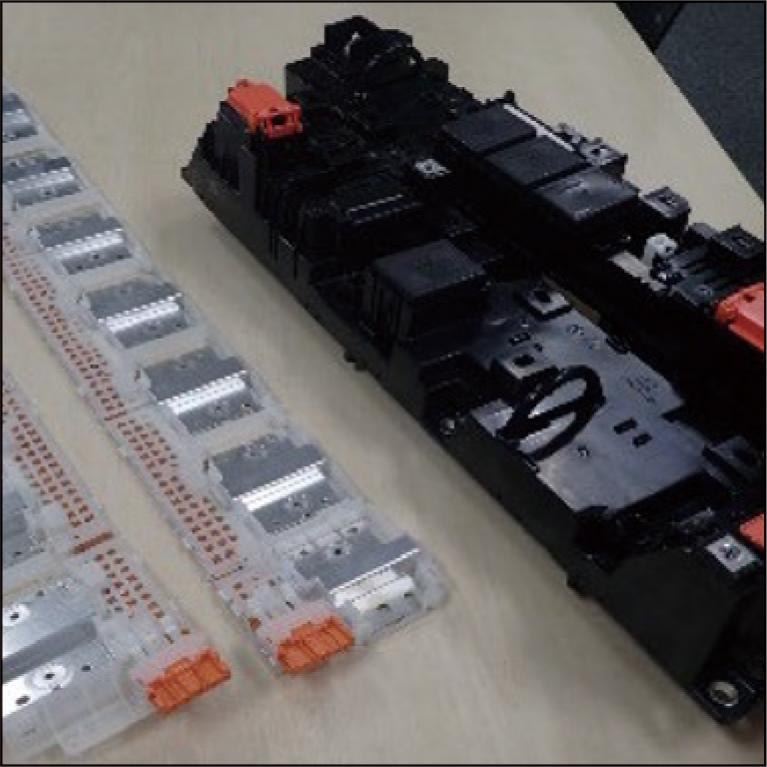

The increase in motor cars, specifically hybrid electric vehicles (HEVs), plug-in hybrid electric Vehicles (PHEVs), and battery electric vehicles (BEVs), is expected to be driven by policies promoting fuel economy and CO2 emission control. In order to support the growth of BEVs, we are developing and mass-producing connection parts such as battery wiring modules, high-pressure junction boxes, and wiring harnesses for battery packs. These connection parts play a significant role in improving the performance of the battery packs by ensuring compact size, space efficiency, and high current capacity. This paper highlights the features and benefits of our battery wiring module and high-voltage junction box as essential components in the battery pack.

2.6 MB

2.6 MB

Steep surges generated by high-voltage inverter-drive motors are expected to cause significant damage on the insulators of magnet wires. Sumitomo Electric Industries, Ltd. has developed a novel magnet wire with uniform closed microcells introduced into the insulation. This paper discusses the excellent dielectric properties of the newly developed magnet wire.

1.6 MB

1.6 MB

The automotive industry is becoming increasingly intellectualized through CASE (Connected, Autonomous, Shared, and Electric) innovations. While development times for in-vehicle systems are lengthening, products must be brought to the market quickly to remain competitive. We are making efforts to utilize digital engineering for design verification of in-vehicle systems in order to derive optimal architectures in a short period. We have applied mathematical optimization to the verification flow of the system architectures with the number of zone ECUs and the number of variations as parameters. This paper presents our efforts to shorten the verification time by combining the derived results with the response surface method, which predicts optimal conditions for the design parameters.

1.7 MB

1.7 MB

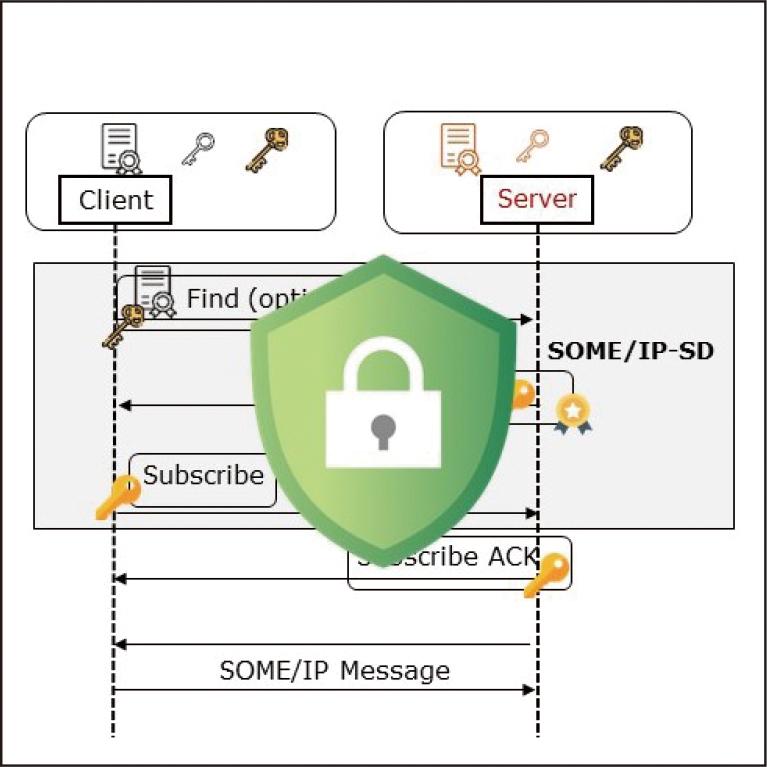

Ethernet and SOME/IP (Scalable service-Oriented MiddlewarE over IP) have been increasingly applied to modern vehicles. Although SOME/IP serves as an automotive middleware solution for control message transmission, it lacks security measures, making it vulnerable to various attacks. To address this issue, we present a security extension protocol for automotive Ethernet. Furthermore, we evaluate the protocol and demonstrate its effectiveness.

1.1 MB

1.1 MB

Driven by evolutions in CASE (connected, autonomous, shared & service, and electric) technology, the need for fast in-vehicle networks has increased, making in-vehicle Ethernet an attractive next-generation communication solution. To comply with the strict communication standards set by the standards organization OPEN Alliance, our focus turned to investigating 100 M Ethernet compatibility. Initial evaluation using existing CAN components revealed disparities in transmission and crosstalk characteristics of wires and connectors. Therefore, we have developed new wires and connectors, as well as terminal processing technology, CAE analysis technology, and communication characteristic evaluation technology, all of which are necessary for the development of high-speed communication components. These efforts ensured compliance with the communication standards. We view high-speed communication components as vital elements of wiring harnesses, and are committed to their ongoing development, recognizing the significance in facilitating efficient in-vehicle communication.

4.9 MB

4.9 MB

With the advancement of CASE technologies, particularly automated driving, the demand for high-volume information processing devices like LiDAR is increasing, necessitating faster in-vehicle data communication. Sumitomo (SEI) Electronic Wire, Inc. is actively engaged in developing and manufacturing information transmission sub-harnesses that comply with new global communication standards to enable high-capacity data communication. Additionally, the company has developed automated processing equipment for the efficient production of widely used connectors in sub-harness processing. This paper provides an overview of in-vehicle equipment trends, communication standards, and our wire and terminal processing technology, which are integral to high-speed communication sub-harnesses that connect these devices.

2.6 MB

2.6 MB

This paper reports on the development of an antenna suitable for 5G millimeter wave (mmWave) communication, incorporating metamaterial technologies such as Electromagnetic Band Gap (EBG) and Artificial Magnetic Conductor (AMC). The goal is to achieve automated driving by utilizing 5G, which offers high-speed, large-capacity, and low-latency features. To enable efficient data communication, particularly for sensing information, the use of mmWave band with a bandwidth of several hundred MHz is required. However, the use of an array antenna consisting of multiple patch antenna elements on the roof of a vehicle poses challenges in terms of radiation characteristics. This study aims to address these challenges through the development of an antenna suitable for 5G mmWave communication.

2.7 MB

2.7 MB

The spread of autonomous driving and the movement toward CASE (connected, autonomous, shared & service, electric) vehicles has led to an increase in the number of devices and electrical circuits in automobiles. However, in order to improve comfort, there is a need to increase the interior space of vehicles, which requires a change in the wiring harness design to fit into smaller and tighter spaces. Meanwhile, the complex nature of wiring harness manufacturing makes it difficult to automate, resulting in a manual-intensive process that requires a large number of workers across global locations. This presents challenges in terms of cost and carbon emissions associated with long-distance shipping to OEM factories. To address these challenges, we have developed e-STEALTH W/H, a new wiring harness that not only increases interior space in vehicles but also enables automation, shifting from labor-intensive processes to localized production for local consumption. The successful adoption of our wiring harness by a major automaker underscores its effectiveness. This paper outlines the structure and key technologies of e-STEALTH W/H and provides insights into our innovative wiring harness solution.

2.2 MB

2.2 MB

In the automotive industry, with the goal of reducing CO2 emissions by improving fuel efficiency, there is a need for high-performance aluminum materials that can contribute to reducing the weight of automotive components. We have been working to improve the strength and heat resistance of aluminum alloys for forged automotive components. By improving the alloy composition and processing methods, we have developed two aluminum alloy wires with higher strength and higher heat resistance than widely used 6000 series aluminum alloys. This paper introduces the development of the aluminum alloy wires and the characteristics of the developed aluminum alloys.

2.1 MB

2.1 MB

The growing emphasis on mitigating global warming has highlighted the need for sustainable solutions in the e-mobility sector. In response, the automotive industry requires traction motors that deliver increased speed, torque, and efficiency. Through the integration of advanced technologies in stator magnet wire and slot cooling, we have successfully developed a downsized stator architecture for traction motors. This innovative design concept maintains maximum torque while achieving significant size reduction. Furthermore, the production process for this stator contributes to a reduction in CO2 emissions by approximately 30%, compared to conventional stators.

1.8 MB

1.8 MB

As the electrification of automobiles progresses, the number of parts used in rolling and sliding environments, such as gears and bearings, which are often used in motors and reducers, is increasing. Therefore, improving their durability and reducing their friction loss are considered to be important. We coat various diamond like carbon (DLC) depending on the application. Among them, it has been confirmed that hydrogen-free DLC has a high friction reduction effect in lubricating oil. In this study, we investigated changes in durability when applying hydrogen-free DLC to gears and the friction reduction effect of hydrogen-free DLC in rolling and sliding environments. As a result, it was confirmed that coated gears with hydrogen-free DLC improve their durability. It was also confirmed that the friction reduction effect of hydrogen-free DLC is higher in environments with “lower viscosity of oil,” “higher rotation speed,” and “higher slip ratio.”

2.2 MB

2.2 MB

To mitigate accidents involving forklifts and people, we have developed a forklift safety support system capable of detecting the presence of people near a forklift. Real-time responsiveness is crucial, necessitating immediate detection and reporting. To address this, we propose utilizing edge computing to enable swift responses. This paper introduces a forklift safety support system leveraging edge AI installed in a compact edge computer. Additionally, we discuss the evaluation of edge AI's accuracy and speed at the edge, along with the examination of techniques to enhance the accuracy efficiently.

2.8 MB

2.8 MB

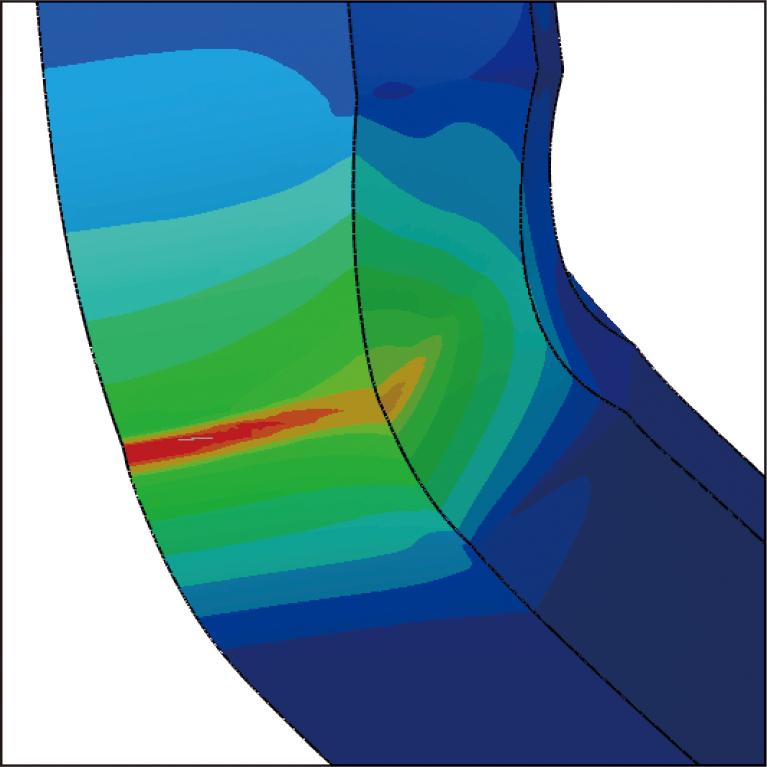

As terminals for automotive connectors become smaller, the copper alloys used for the terminals are becoming thinner and stronger. Terminals are formed mainly by bending, but the higher strength of copper alloys makes bending cracks more likely to occur. In the past, this problem was handled by trial and error based on experience, but in order to cope with the recent short development period, a technique for predicting bending cracks using CAE is required. Although special elasto-plastic analysis reflecting the crystallinity of metals has been reported as a conventional prediction technique for bending cracks, it has been difficult to apply this technique to actual copper alloys for terminals. Therefore, based on the occurrence mechanism of bending cracks, we considered that shear deformation resistance in the thickness direction has a significant influence on the occurrence of bending cracks, and developed a shear test method for thin sheets in the thickness direction. Based on the measurement results, it becomes possible to predict the occurrence of bending cracks by simulating bending cracks using the general elasto-plastic analysis.

1.9 MB

1.9 MB

Communication frequency in telecommunications has been increasing to improve data transmission speed and capacity. However, this increase also raises the possibility of unintentional radiated emissions from communication cables, leading to electromagnetic compatibility (EMC) problems. From the viewpoint of radiation, we examined the transmission and radiation characteristics of unshielded twisted pair (UTP) cable commonly used in local area networks and in-vehicle communication networks. The examination confirmed that the UTP cable emits a portion of the transmitting signal within a certain frequency band. This emission follows the same mechanism as a leaky cable. We verified that the equation derived from the leaky cable mechanism can explain the relationship between the radiation bandwidth and the radiation angle. This paper introduces the radiated emission from UTP cable and explains the radiation mechanism in detail. Additionally, we provide a guideline on how to avoid potential EMC problem related to UTP cable.

2.7 MB

2.7 MB

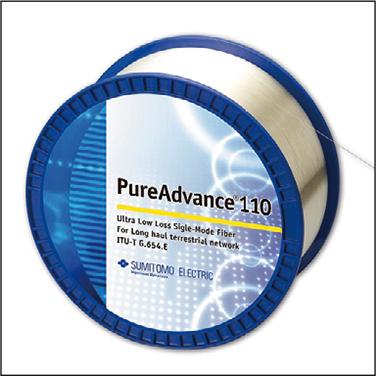

Thinner optical cables are required for data center networks to meet the increasing demand of communication traffic. For these cables thinner optical fibers are essential, and one of the concerns in reducing the optical fiber diameter is the increase in attenuation by microbending in the cabling process. It is necessary to adjust the optical fiber structure based on an analytical formula that systematically estimates the effects of structural parameters. Based on Cocchini's established method for conventional optical fibers with a coating diameter of 250 μm, we have derived an analytical formula to accurately predict the microbending attenuation of optical fibers with a smaller diameter of 165 μm or less.

1.5 MB

1.5 MB

With the increasing amount of internet traffic, there is a growing demand for high-capacity optical fiber communication not only for long-haul communication but also for inter-data centers communication. We have been developing InP modulators and driver ICs. Recently, we have developed a modulator module and successfully demonstrated 1 Tbit/s fiber transmission with a low power consumption of less than 3 W. We have also developed a spot size converter using 3D printing technology and achieved a low loss of 9.5 dB as part of the modulator module, confirming its reliability for Telcordia standards.

2.6 MB

2.6 MB

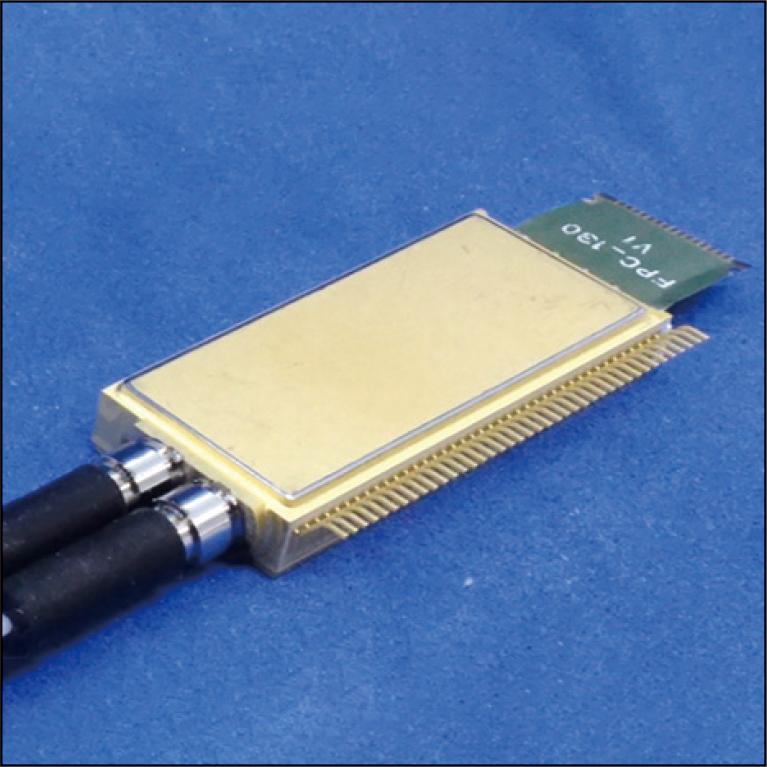

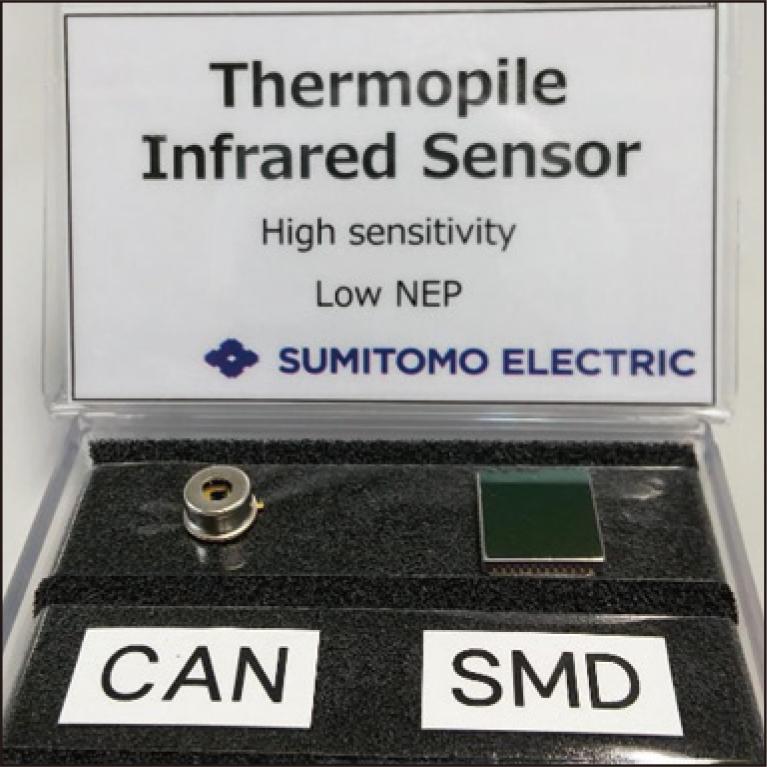

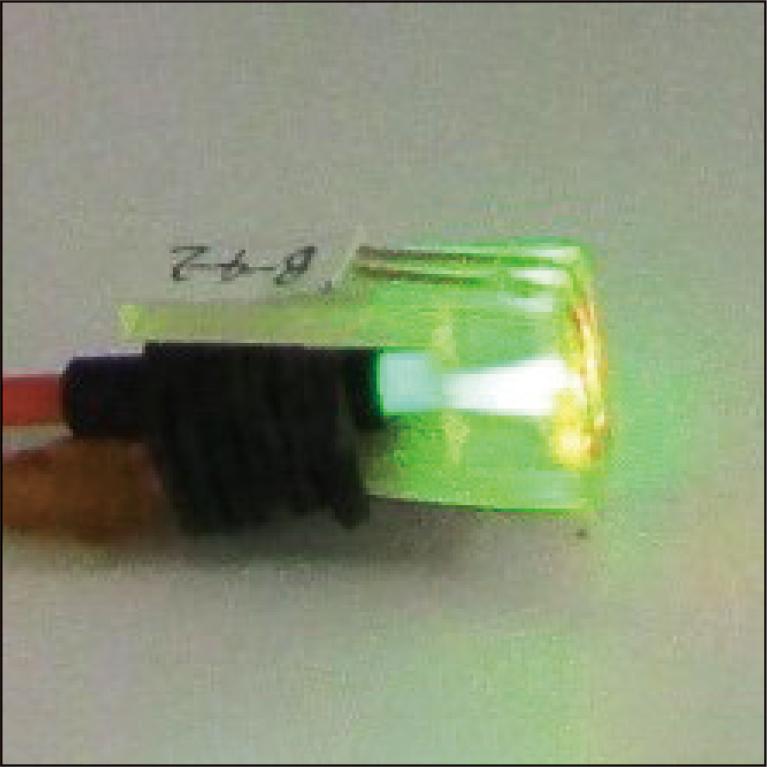

This paper reports on the characteristics of a thermopile infrared sensor using nanostructured Si-Ge thermoelectric materials. While thermopile infrared sensors have the advantage of operating without power consumption, they have low sensitivity. To address this limitation, we have developed nanostructured Si-Ge thermoelectric materials that are expected to have a low thermal conductivity and a high Seebeck coefficient. With a thermal conductivity of 1/8 (0.8 W/(m·K)) and a Seebeck coefficient 2.8 times higher (330 μV/K) than that of conventional Si-Ge crystals, the nanostructured Si-Ge thermoelectric materials are expected to enhance the sensitivity of the thermopile infrared sensor. The thermopile infrared sensor using these materials achieved a sensitivity of 1,200 V/W at pressures below 1×10-1 Pa, demonstrating high sensitivity.

1.6 MB

1.6 MB

The Wi-SUN FAN (Wireless Smart Utility Network for Field Area Network profile) was initiated in 2012 as an international wireless communication standard for next-generation smart meters. The certification process for the new specification, Wi-SUN FAN 1.1, which includes improvements in communication speed, distance, and low power consumption, is expected to launch in 2024. This paper highlights the features of Wi-SUN FAN in relation to its compatibility with smart cities and provides an overview of our efforts in this field.

5.1 MB

5.1 MB

We have successfully developed a forced air-cooled 150 kW isolated bidirectional DC–DC converter, aiming to achieve a power density of 2 kW/L, equivalent to a water-cooled system. This was achieved by improving the cooling performance of the transformer, a major component, integrating the cooler for the power semiconductor and transformer, reducing the switching loss of the power semiconductor, and implementing a novel control system that minimizes the overall loss. These efforts have led to the miniaturization of our converter, comparable to our water-cooled isolated bidirectional DC-DC converter.

2.7 MB

2.7 MB

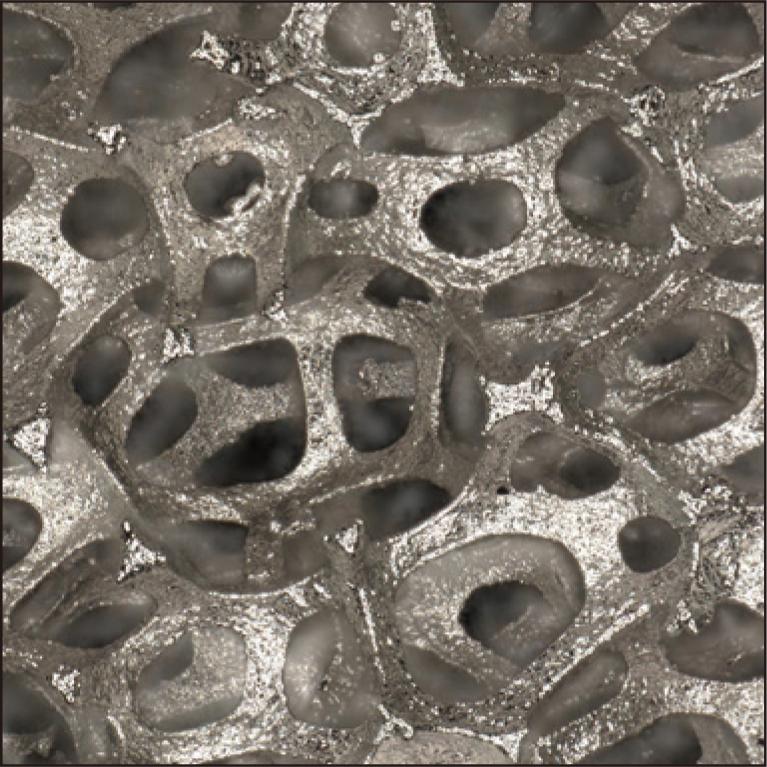

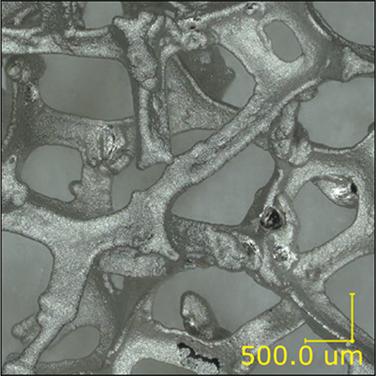

In response to the tightening international environmental regulations such as carbon neutrality and CO2 emission reduction, the importance of thermal management has been emphasized in electronic products and automotive electrified products, where heat generation density is increasing year by year. In addition to the cooling mechanisms such as air cooling and water cooling, which have been the mainstream so far, there is an anticipated expansion of cooling mechanisms with excellent heat dissipation capabilities, such as heat pumps, vapor chambers, and heat storage systems. The effectiveness of these systems largely depends on the capabilities of heat exchangers and heat storage devices. To enhance their performance, we have developed porous metal materials that have both high thermal conductivity, high porosity, and micropore size. These materials can contribute to the reduction of CO2 emissions by reducing the energy required for cooling.

2.4 MB

2.4 MB

We have developed a portable measuring instrument that uses diamond nitrogen-vacancy (NV) centers. It operates on the USB 3.0 power supply of a laptop computer, consuming only 3 W of power. We use high-quality diamonds produced by Sumitomo Electric Industries, Ltd. and NHV Corporation's electron beam processing to create a sensitive NV center. The device's portability is achieved through low power consumption in both the optics and the microwave source. This is made possible by a diamond corner cube that increases the photocurrent by 2.1 times compared to planar diamonds and a microwave resonator using a λ/4 transformer and a λ/4 open stub that reduces the power by 20 dB. The sensor head is compact, measuring 5 × 10 × 20 mm, and allows for magnetic field and temperature measurements. The successful implementation of these features contributes to the use of diamond sensors in various applications.

2.9 MB

2.9 MB

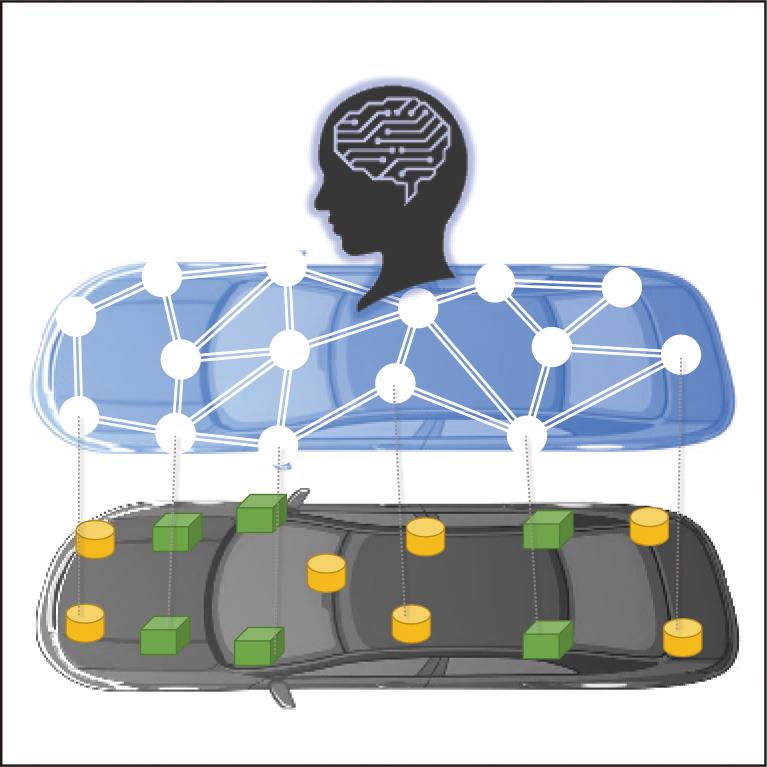

In the architecture of automotive electronic devices, functions have been conventionally implemented with discrete ECUs. The trend in these functions in the next-generation architecture, which is required to meet the needs for expandability and flexibility, is toward divided implementation into a brain (central ECU) in which control functions are integrated, and hands and feet (zone ECUs) that drive sensors and loads.

0.8 MB

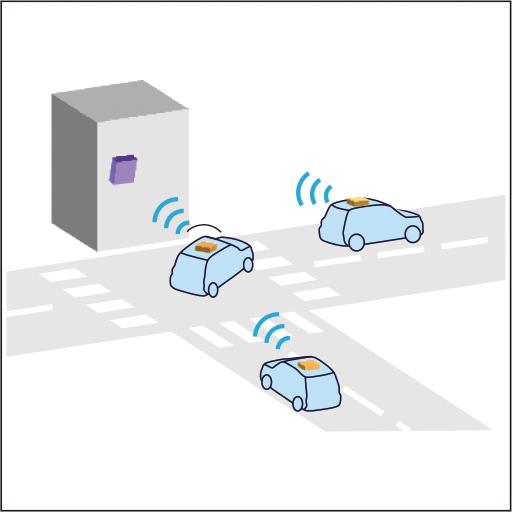

Traffic signal control helps improve traffic safety, mitigate congestion, and reduce CO2 emissions by appropriately determining the green light duration and other signal control parameters suitable for traffic condition of each direction at intersections. Conventionally, vehicle detectors have been used to know the traffic conditions. However, the cost incurred by their installation and maintenance has emerged as a challenge.

0.5 MB

In recent years, communication traffic has increased rapidly due to progress in cloud computing, video streaming services, and support for 5G. Therefore, large data centers (DCs) are currently being built. Optic cables connecting DCs are mostly installed in a duct. There are instances where micro-duct optic cables are used, being suitable for the installation method that pushes the cable into the duct by feeding high-pressure air (air-blowing method). Because the interiors of DCs are required to be flame retardant, there is a need for a connection point connecting to a non-flame-retardant optic cable used outside the DC. Sumitomo Electric Industries, Ltd. has developed and launched a 288-fiber flame-retardant microduct optic cable, which can be used inside and also outside DCs for continuous installation without a connection point.

1 MB

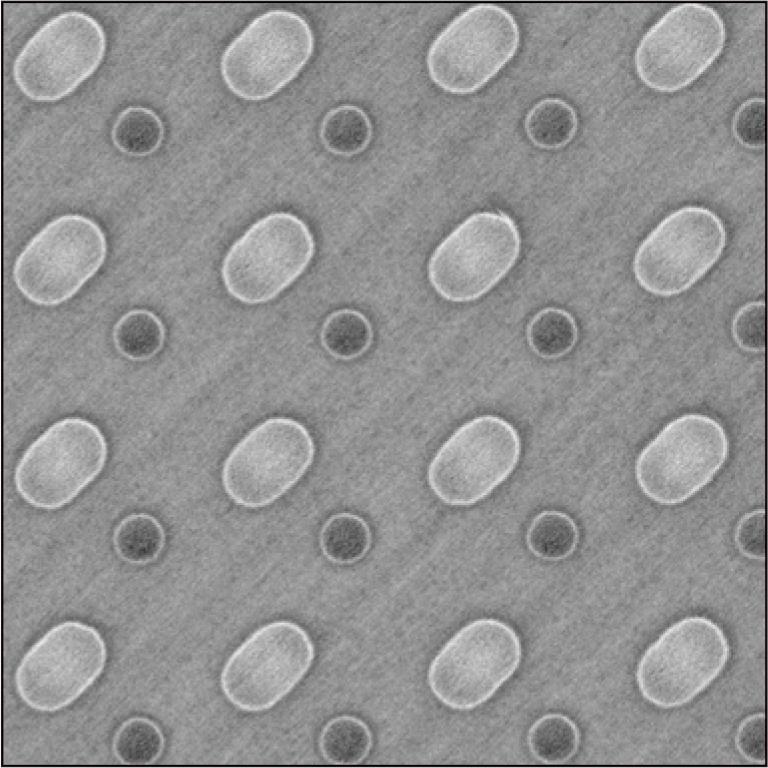

Our Poreflon porous materials made from stretched polytetrafluoroethylene (PTFE) are used in various industrial fields. For example, in semiconductor-related applications, higher cleanliness levels are required for process chemical liquids due to ever-higher integration. There has been a growing need for separation membranes with smaller pore diameters. To meet the need, we have developed Poreflon nano, proprietary PTFE membranes with nano-pores. This paper describes the specifications and applications of the new filtration module, which houses Poreflon nano in an all-fluororesin package.

0.9 MB

In the field of cutting small parts—small-diameter and precision parts—used in industries such as automotive, electronics, and medical parts, there is a growing need for tools that can reduce burrs, chattering, and poorly machined surfaces and improve the quality of machining. To meet this need, Sumitomo Electric Industries, Ltd. has developed the SL Type, which is a G-class three-dimensional (3D) chip breaker for small lathes that achieves high machining quality due to its superb sharpness. This article describes its features and performance.

3 MB

The silicon carbide (SiC) power device market is growing each year due to the rapid proliferation of electric vehicles and photovoltaic power generation systems. Accordingly, there is an upward capital investment trend, such as planned increases in production volume by a factor of two to five within a couple of years. Meanwhile, there is a trend towards the development and commercialization of 8-inch (200 mm) SiC wafers, with 6-inch (150 mm) SiC wafers currently being the mainstream. Technology development is actively underway to manufacture SiC power devices at a reduced cost.

0.6 MB

Semiconductor lasers offer better features than existing laser beam sources, being smaller in size and achieving higher efficiency and a longer service life. Their applications in society are advancing in many fields such as health care, sensing, and sheet-metal working. Moreover, they are drawing great attention from the perspective of carbon neutrality.

1.1 MB

Video distribution traffic accounts for 65-70% of the downstream access network traffic, which has continued to grow in recent years. Advances in video image quality and video compression technologies, coupled with standardization efforts, have led to a significant increase in the maximum required bandwidth per broadcasting channel. Specifically, over the last two decades, the maximum content bitrate has multiplied by approximately 40 times (pre-compression), and 20 times (post-compression) for IPTV, while domestic radio frequency broadcasting has shown the pace of 5 times. At the same time, the future growth of the market is anticipated to be driven not only by the transition to 8K video but also by the integration of Extended Reality (XR) video services that combine 360° 3D video, AI, and digital twin technologies. Taking this opportunity, this paper reviews the trends in video communication technology and the initiatives of Sumitomo Electric Industries, Ltd. The paper also discusses various key indexes required for all-optical and wireless networks connecting cloud computing to homes and workplaces, with a particular focus on what is called the Motion-to-Photon latency, which is essential for realizing immersive and interactive 3D and XR video distribution services, and considers its impact on other key indexes.

2.6 MB

2.6 MB

Intelligent communication technology is an indispensable part of the infrastructure that supports modern society. In particular, wireless communication systems using high-frequency radio wave carriers have made remarkable progress in the last 30 years. In 2020, 5th-generation services started to realize high-data-rate transmission and low signal latency. The environments in which wireless communication networks operate have expanded to include the open sea and low earth orbit. To date, we have developed many kinds of commercial transmission devices for optical wired and wireless communications. We were the first company in the world to successfully mass produce and commercially ship Gallium Nitride high electron mobility transistors (GaN HEMTs), a key device for cell phone base stations, and have the top market share. This paper describes compound semiconductor devices represented by GaN HEMTs as well as novel crystal and device technology for discontinuous performance enhancement.

3 MB

3 MB

Climate change poses a global challenge that necessitates the reduction of carbon dioxide (CO2) emissions. To reduce CO2 emissions from motor vehicles, which are major emission sources, it is important not only to improve vehicle exhaust performance, but also to improve infrastructure such as traffic signal control at intersections to mitigate traffic congestion and energy consumption. A quantitative evaluation of the effects resulting from traffic signal control improvements is essential for their dissemination. Currently, however, there is no well-established method to calculate CO2 emissions of vehicles traveling through intersections. We have developed a CO2 emissions calculation model intended for widespread adoption. This model facilitates the quantitative evaluation of CO2 emissions reduction resulting from traffic signal control improvements.

0.8 MB

0.8 MB

The global need for pedestrian detectors is increasing to improve traffic safety and efficiency. In order to achieve accurate detection at intersections, the detectors need to be placed in the right locations. However, constructing new poles requires much effort and cost, making it essential to utilize existing poles for widespread deployment of the detectors. Meanwhile, achieving effective pedestrian detection on both far and near sides presents challenges due to the limited sensor viewing angles. Additionally, many sensors are unable to detect pedestrians directly beneath them, thereby restricting the possible installation locations. To overcome these challenges, we have developed a cost-effective radar system with a wide vertical coverage angle, offering improved installation flexibility. This paper introduces the innovative radar and presents experimental results demonstrating its expanded detection area.

2.7 MB

2.7 MB

In recent years, the convergence of several services and information technologies has revolutionized our daily lives. However, failures in communication infrastructure can have profound consequences, necessitating increased reliability and availability of communication equipment. This paper focuses on our research and development efforts in high-speed Ethernet equipment, specifically addressing MC-LAG (multi-chassis link aggregation) and precision time synchronization in supporting high-quality 5G wireless systems.

1.9 MB

1.9 MB

To address the rapid increase in data traffic, data centers have increased the number of channels. However, current systems use one semiconductor laser per channel, resulting in higher power consumption and costs due to the increased number of components. To overcome these challenges, a new approach has been proposed, where light from a single laser with high output power is branched to create multiple channels. However, existing telecommunication lasers have reached the limit in achieving high output power with single-mode lasing. Therefore, we have conducted research on 1.3-μm-wavelength InP-based photonic-crystal surface-emitting lasers (PCSELs) as a next-generation semiconductor laser that can achieve both single-mode lasing and high output power. We have demonstrated single-mode operation with a high output power of over 200 mW under continuous-wave conditions at room temperature by using dry-etching and regrowth techniques. In addition, we have achieved a high output power of 4.6 W in short-pulsed operation. These results suggest that PCSELs can be used not only for communications but also for sensing applications.

2.4 MB

2.4 MB

Sumitomo Electric Industries, Ltd. developed polytetrafluoroethylene (PTFE) porous membranes ahead of the world. In the early 2000s, utilizing the membranes, the Company develop hollow fiber membrane water modules with excellent chemical resistance and strengths. The modules have been widely applied to water purification, sewage treatment, and industrial wastewater treatment around the world. With the increasing demands for the recovery of salt components, we focused on the application of these modules to membrane distillation for the separation of trace components such as salt in seawater and rare-earth elements in water resources, taking advantage of the excellent hydrophobicity of PTFE. This paper reports on the development of a PTFE hollow fiber membrane with superior water pressure resistance and gas permeability, both of which are critical for membrane distillation.

2.4 MB

2.4 MB

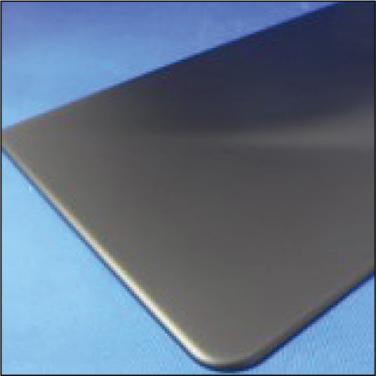

Nissin Ion Equipment Co., Ltd. conducted research on electron transport properties of an argon-ion-implanted amorphous InGaZnO (a-IGZO) film deposited on a glass substrate. The research obtained valuable data on electron concentration and Hall mobility of the film at various depths from the surface. The result shows that the a-IGZO film has a high electron concentration in deep regions compared with an argon plasma-treated a-IGZO film. In addition, the company estimated the argon stopping powers of a-IGZO and the donor level of 0.05-0.1 eV below conduction band bottom energy, which can be applied to resistance control for a-IGZO device processing.

2.7 MB

2.7 MB