Industrial Materials

Cutting and Grinding Tools

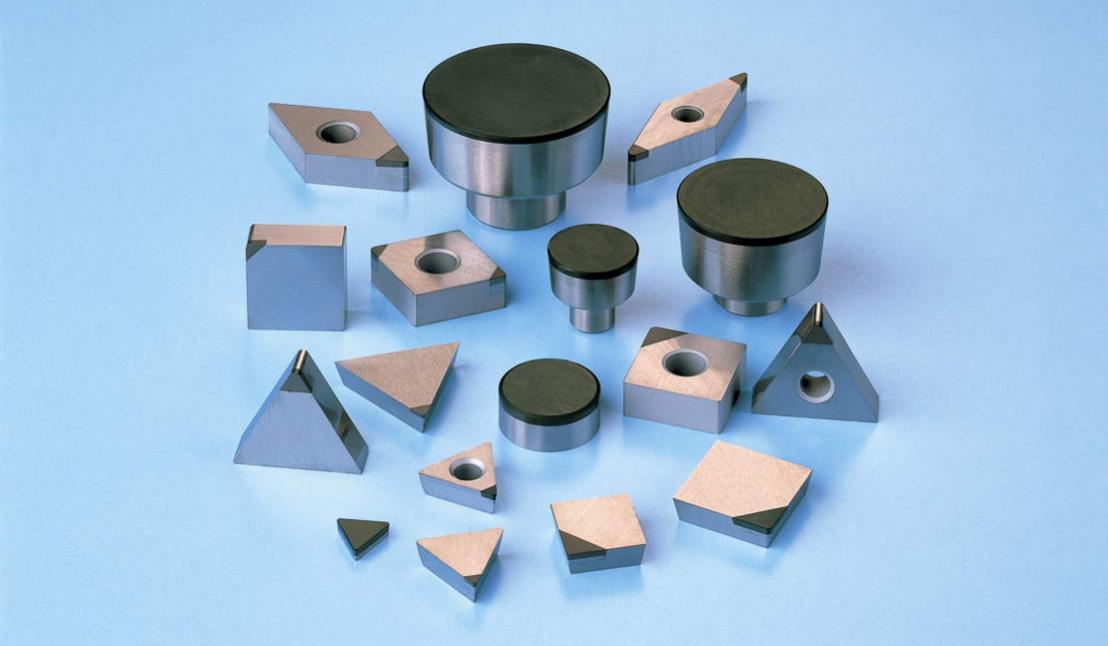

CBN Tools

Cubic boron nitride (CBN) tools—second only to diamond in hardness and far less reactive with iron—enable the transition from grinding to cutting in hardened steel applications. They offer high-precision, high-efficiency machining of cast iron and sintered alloys. We develop advanced CBN tools to meet the increasing demands for machining difficult-to-cut materials, achieving greater accuracy while reducing environmental impact.

Coated Carbide Tools

Advanced coated tools feature hard carbide substrates coated with wear-resistant composite nitrides—such as those from groups III–V, aluminum, and silicon—along with oxidation-resistant layers like alumina, using chemical vapor deposition (CVD) or physical vapor deposition (PVD) methods. Advances in both coating and substrate technologies have enabled more efficient machining and promoted cost-effective, environmentally sustainable manufacturing.

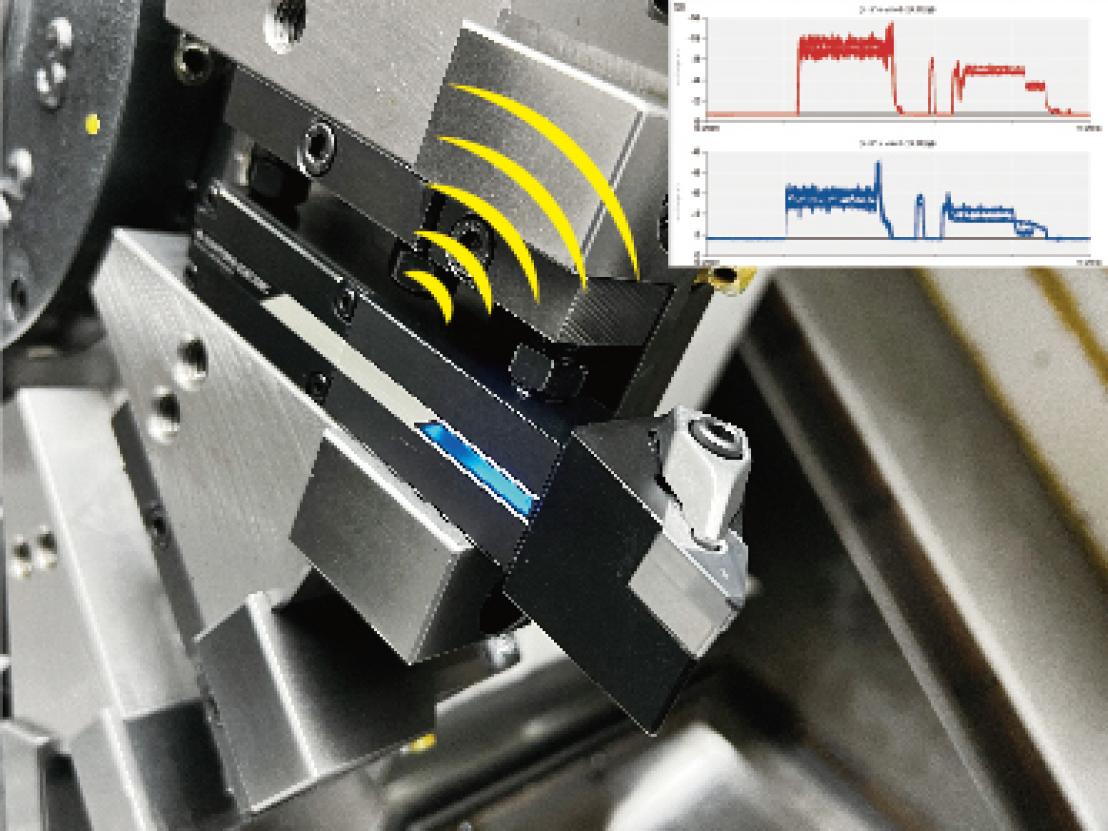

Sensing Tools

We are developing cutting tool holders with built-in sensors that measure cutting forces during machining and wirelessly transmit the data. This enables real-time visualization of machining loads on production lines, supporting process optimization, root cause analysis of defects, and cost reduction. In parallel, we are advancing technologies to detect tool breakage and other abnormalities during operation.

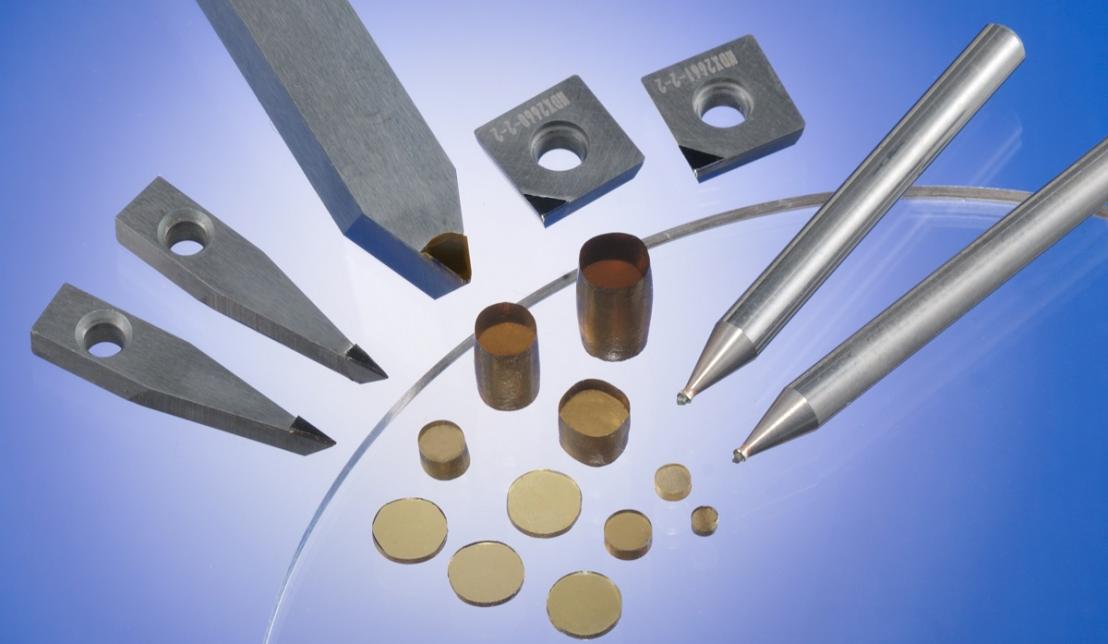

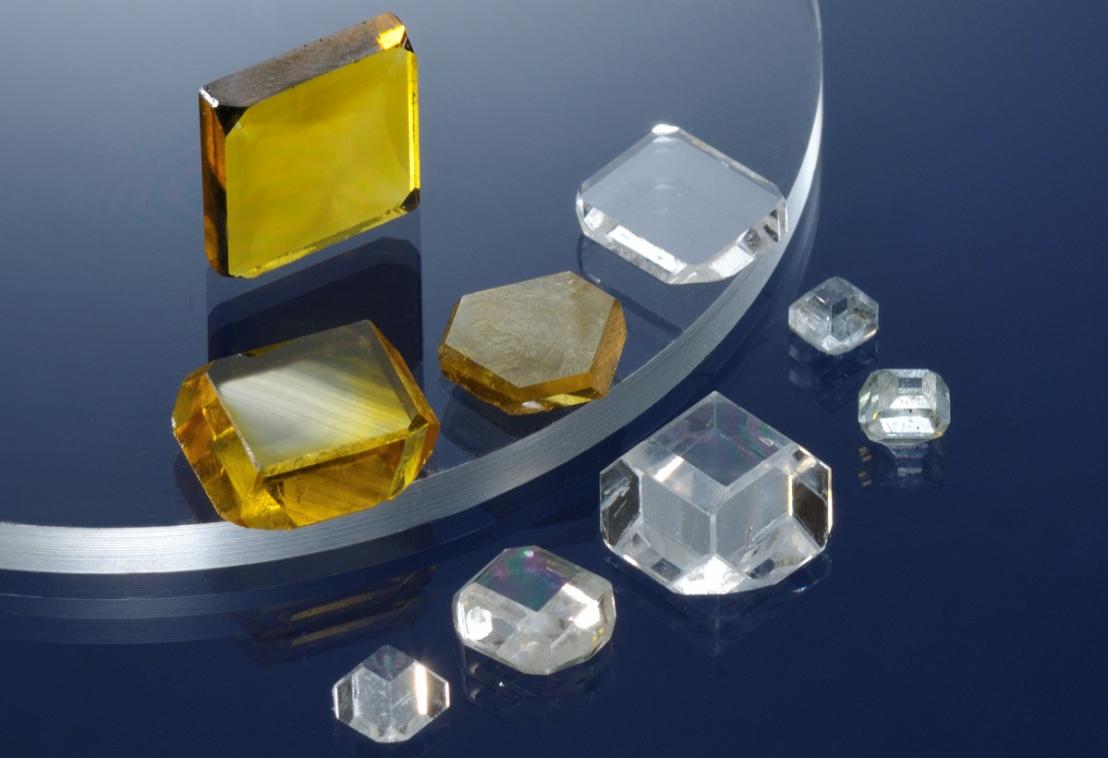

Diamond Materials

Synthetic Diamond

We harness our proprietary ultra-high-pressure technologies to synthesize diamonds and create novel diamond materials with enhanced functionalities. In addition to conventional applications in cutting tools and optical components, synthetic diamonds are gaining attention as next-generation semiconductor substrates with ultra-low energy loss, and as materials for broad-range magnetic sensors.

Cemented Carbide Materials

Cemented Carbide Materials

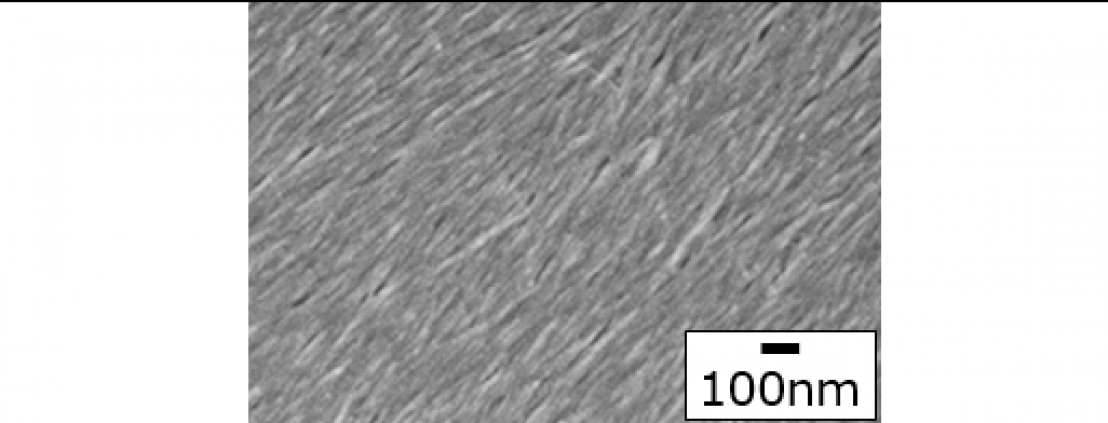

Cemented carbide, primarily composed of tungsten carbide (WC), is the most widely used material for indexable inserts, drills, and end mills. It plays a vital role in the manufacturing of automobiles and high-performance mobile devices. Our ultra-fine grain carbide—engineered with atomic-level microstructure control—delivers exceptional chipping resistance, enabling longer tool life and enhanced machining efficiency.

Composite Wires

High-Strength Conductive Materials

These composite wires feature oxygen-free copper embedded in stainless steel, offering a unique combination of high electrical conductivity, mechanical strength, elasticity, and corrosion resistance. Our proprietary wire-drawing technology enables ultra-fine processing down to φ30 µm. By adjusting the copper content, conductivity can be tuned within a range of 30% to 60%.

Separation Membranes

Nano Separation Membranes

We develop water treatment membrane modules using Poreflon™—a porous fluoropolymer with excellent chemical resistance, durability, water permeability, and heat resistance. These modules are widely used in countries around the world. Aiming to reduce environmental impact through higher performance and added value, we are advancing the development of new membrane technologies for nanomaterial removal and next-generation separation membrane modules.

New Materials

metacol™

"metacol™" is a next-generation material made from CO₂ and metal, offering a new sustainable option for both manufacturers and users. It allows manufacturers and consumers alike to contribute to carbon neutrality and supports the realization of a more sustainable society.