Finally Realizing High-Strength Carbon Nanotubes for the First Time

Ultra-High Strength Carbon Nanotube Yarn Made by New Growth Method

Soichiro Okubo

Specialist, Frontier Technologies Laboratory

Carbon nanotubes (CNTs) have dreamlike properties: lighter than aluminum, more than 20 times the tensile strength of steel, and electrical conductivity superior to that of copper. For this reason, since their structure was elucidated in 1991, it has been expected that CNTs would be used as next-generation electric wire materials. However, the superior performance of the individual fibers (single crystals) is lost when they are made into yarn. Because of this drawback, no one has been able to bring it to market, even though researchers around the world have tried hard to do so.

Our CNT wire material development also took a difficult path to be recognized as a research theme. Thanks to my colleagues who understood the significance of this technique, my supervisors and directors who accepted the challenge, taking a backward-design approach, and all the related institutions that cooperated in our joint research, we finally achieved a roadmap to practical application as an electric wire material after 15 years of research. Now, I am very excited about the next vision that lies ahead.

What are carbon nanotubes (CNTs), in the first place?

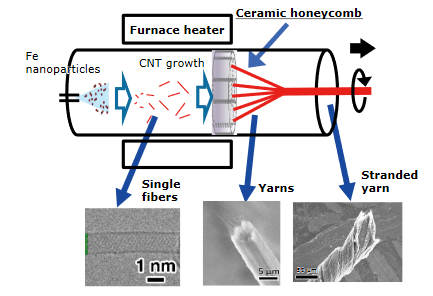

When nano particles of transition metals such as iron, nickel, and cobalt react with hydrocarbon feedstock at high temperatures to soak up carbon (carburization), the excess carbon accumulates on the surface of the nano particles and begins to grow, eventually forming a tube with a particle-size diameter. This is CNT. Once the carbon in the metal is exhausted, no further growth occurs, but we can sustain this growth by replenishing carbon gas. The CNTs obtained by conventional growth methods, however, are limited in their applications because they are about 1 cm in length at the longest and the quality is unstable.

Honeycomb holds the key to overcoming weaknesses in carbon nanotube growth

The primary reasons for the poor properties of CNT yarns were the extremely short length of each single fiber (several tens of microns) and the technical difficulty of aligning and assembling these fibers. However, the breakthrough came suddenly. During a joint research project with the University of Tsukuba, conditions accidentally set by a student led to the discovery of the almost perfect CNTs lining up neatly at the end of narrow channels and growing to several centimeters. This finding inspired us to try an unprecedented manufacturing device utilizing the narrow channels of commercially available, inexpensive ceramic honeycomb. Our proprietary CNT wire material was thus obtained and achieved a world record strength of 14 GPa (based on top laboratory data for resin-composited wire), exceeding even that of carbon fiber (up to 7 GPa).

Significant chance for use in space elevators

It is said that the use of carbon fiber composite materials in aircraft has reduced fuel consumption of the Boeing 787 by 25%. If that is the case, using our CNTs, which are far stronger than conventional carbon fiber, in structural materials for aircraft, automobiles, and drones would further improve fuel efficiency by reducing weight. In addition, a national project in which we are currently participating aims to develop it as an impact-resistant material, envisioning its use as a safety component to protect automobile passengers and as a high-performance protector for athletes. With future applications in space elevators in our sights, our CNTs have unlimited potential.

Related information

・"Novel Carbon Nanofibers Bridge-Grown in Carburized Iron Substrate," SEI TECHNICAL REVIEW No. 79

・"Fabrication of high-strength carbon nanotube bundles using iron oxides co-assisted chemical vapor deposition," Applied Physics Letters 115, 023106 (2019). doi: 10.1063/1.5098370

・"Mechanical Properties of Carbon Nanotube Yarns Produced by Floating-Bridge Method," the 80th JSAP Autumn Meeting 2019

・"Fast-Flow-Assisted Floating-Catalyst Chemical Vapor Deposition for Direct Fabrication of Carbon Nanotube Fibers," NT21, Rice University, USA

SUMITOMO ELECTRIC TECHNICAL REVIEW

A journal of technical papers explaining the Sumitomo Electric’s technologies. Technical papers are available in PDF format.

Learn more