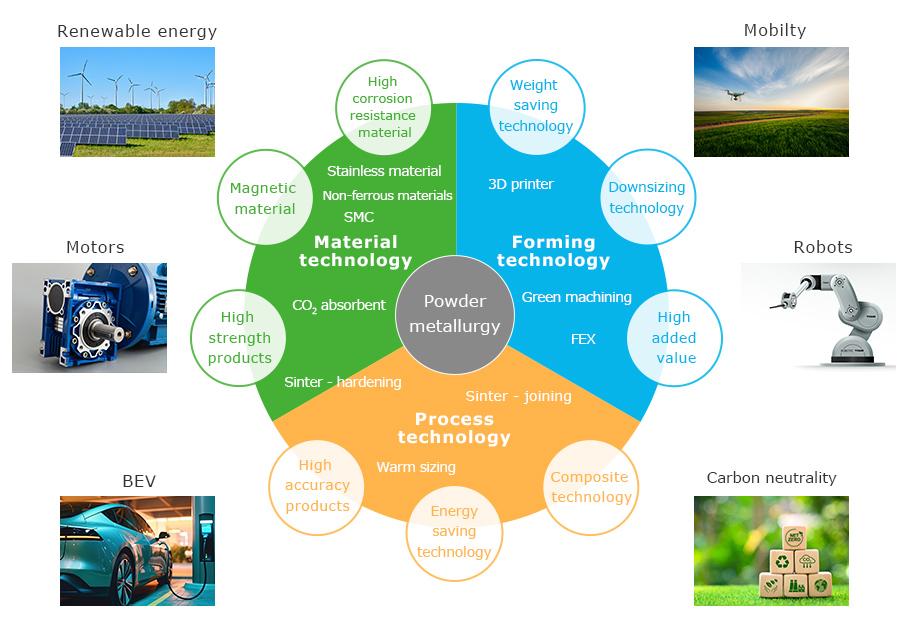

Technology Summary

We develop innovative products using sophisticated core technology

P/M Development Center “PMEC”

What is PMEC ?

PMEC stands for “Powder Metallurgy Engineering Center”, a development center that was established in 2013 at the Okayama headquarters of “Sumitomo Electric Sintered Alloy, Ltd.” , with a showroom for the latest sintering technology and various evaluation facilities.

Please come and visit us.

What we can do with our technologies ?

Optimization Proposals using CAE - Computer-Aided Engineering -

Proposal of shape suitable for sintering in terms of stress relaxation relaxation through collaborative design

Green Machining

Elimination of deburring of small holes and internal cross holes that are difficult to deburr in general

Sinter-Hardening Technology

Cost reduction by using materials and equipment for simultaneous execution of sintering and hardening

Tooth Profile Design Technology for Internal Gear Oil Pump Rotors

Proposal of tooth profile that satisfies customer's required performance with original tooth profile design technology / Consistent system from design → prototype production → evaluation

Sinter-brazing joining technology

Manufacture of hollow products by integrating two or more parts at the same time as sintering

Warm Sizing Technology combined both strength and accuracy

Manufacture of high-strength and high-precision products through marten site while restraining the product inside the tools