Tooth Profile Design Technology for Internal Gear Oil Pump Rotors

As the automobile industry undergoes a paradigm shift to EVs, our flagship internal gear oil pump perfectly suits more automotive applications than ever before.

In addition to conventional applications such as engine lubrication and oil pressurization in AT (Automatic) and CVT (Continuously Variable) transmissions, our oil pumps are increasingly being used for e-axle mechanisms in hybrid & battery EV’s (HEV & BEV), where they serve to enhance gear lubrication and motor cooling.

In addition to these new applications, our internal gear oil pump rotors are already widely used outside of the automotive field in applications such as industrial machinery, and demand is ever-diversifying as new technologies continue to emerge.

As your needs develop, we are happy to work closely with you to achieve the optimal tooth profile design and oil intake/discharge port shape for your application.

Proposed applications : Oil pumps for lubrication, cooling, and pressurization

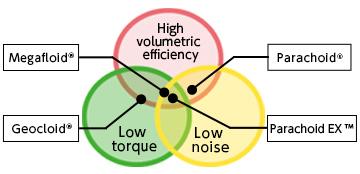

1. Sumitomo’s Unique Tooth Profiles

Thanks to our unique tooth profile design technology, we are able to propose the optimized tooth profile to meet your needs.

| Tooth profile: | Parachoid® 【Trochoid curve】 |

Parachoid EX TM 【Trochoid curve】 |

Megafloid® 【Cycloid curve】 |

Geocloid® 【Original tooth profile】 |

|---|---|---|---|---|

| Shape: |  |

|

|

|

| Year developed: | 1980 | 2012 | 2003 | 2008 |

| Characteristics: | Equivalent volumetric efficiency | |||

| Larger ←————————————→ Smaller | ||||

| Noise: Excellent | Noise: Very Good | Noise: Good | Noise: Average | |

| Size*: | 100% | 95% (5% smaller) | 93% (7% smaller) | 86% (14% smaller) |

*These values are representative of when the theoretical discharge volume, overall length, and number of teeth are the same as our benchmark Parachoid® and the minor diameter of inner rotor can be reduced.

Optimal tooth profile

We excel in proposing the optimal tooth profile to fit our customer’s application and requests.

2. Oil Pump Evaluation Technology

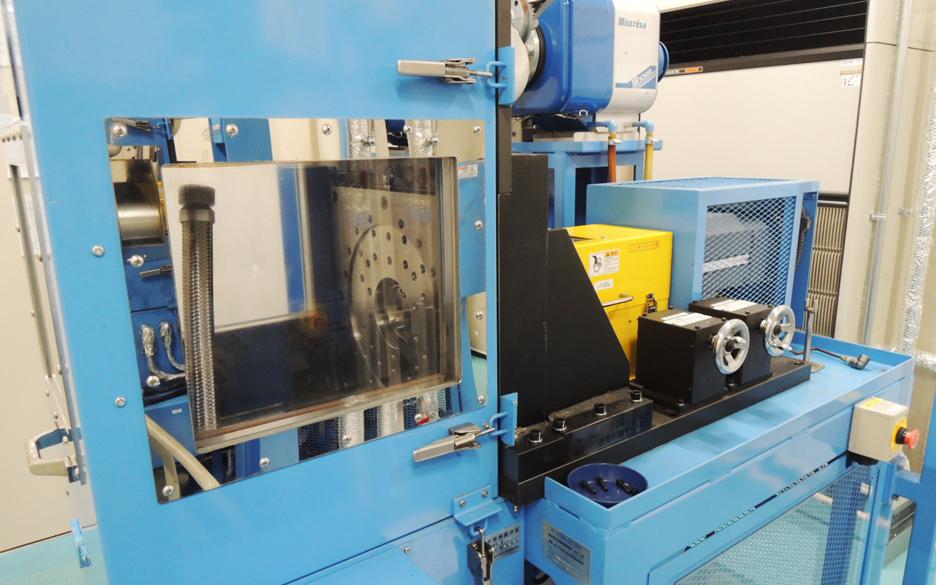

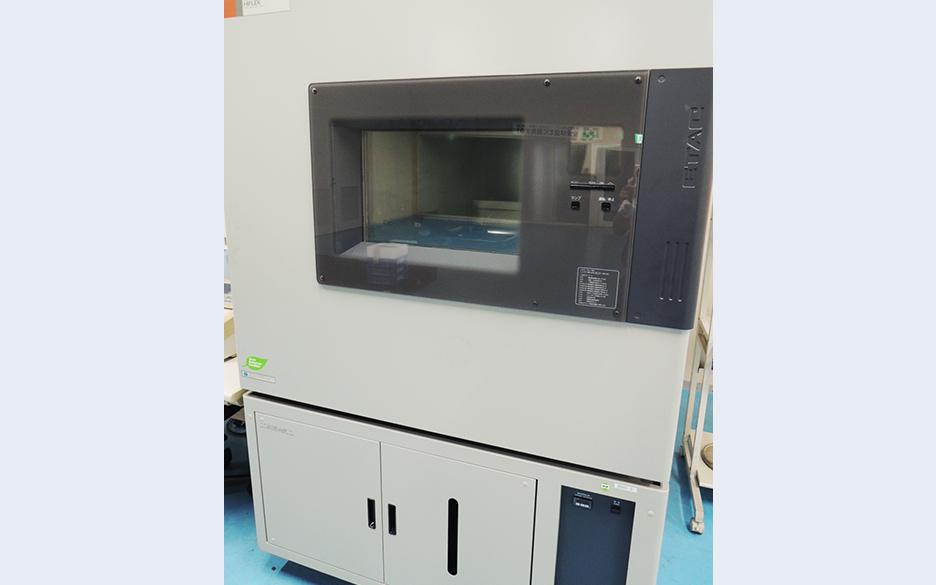

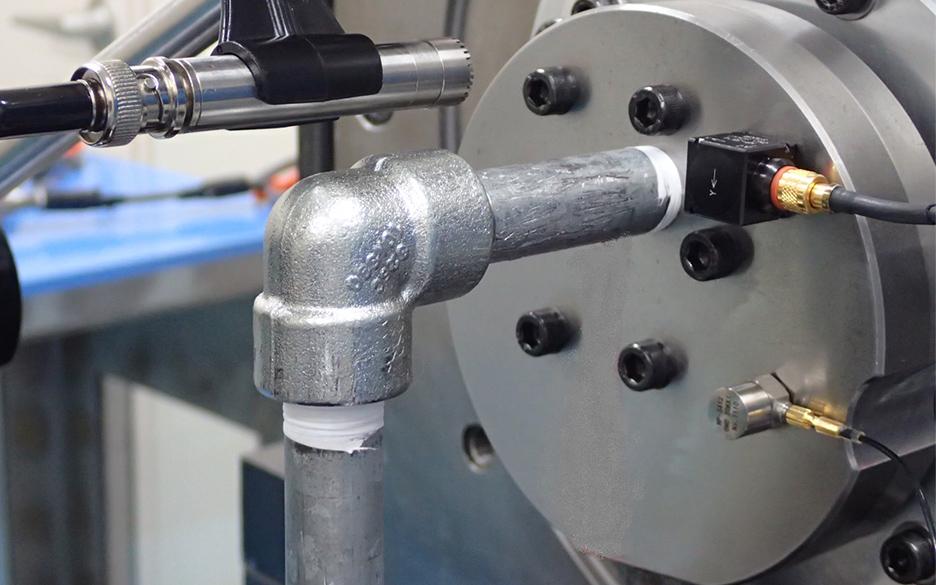

Using our independently-developed testing equipment, we are able to do in-house testing of oil pump performance, durability, and noise & vibration & harshness (NVH) characteristics, contributing greatly to our own development of oil pump-related technologies, and in turn supporting our customers’ ongoing innovation.

| Basic Performance (4 testing machines) |

Durability (4 testing machines) |

NVH Characteristics (1 testing machine) |

|---|---|---|

| ・Discharge volume (Volumetric efficiency) ・Driving torque (Mechanical efficiency) ・Overall efficiency (Pump efficiency) ・Discharge pressure pulsation ・Suction performance ・Performance at low temperature (-40℃) |

・Accelerated durability testing (high load/long duration) ・Cycle durability ・Seizing resistance |

・Overall sound pressure/vibration ・Frequency analysis (Rotor rotational order/mesh order) ・Tracking analysis (Campbell diagram) ・Audio recording data analysis ・Sound quality analysis (Loudness, etc.) |