Sinter-Hardening Technology

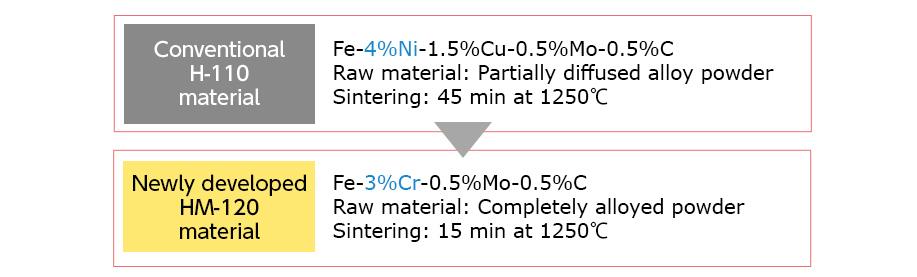

In anticipation of the increasing cost and scarcity of rare metals, Sumitomo has developed a high strength, nickel free material in conjunction with sinter hardening technology that rapidly cools parts after sintering to confer improved mechanical properties.

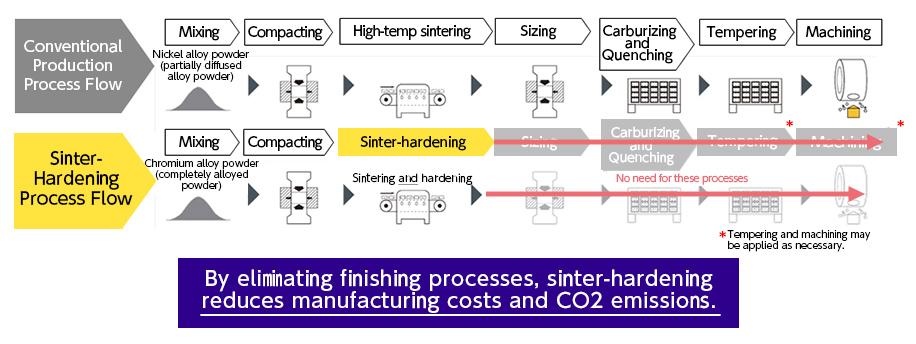

This technology is also environmentally friendly, allowing for reduced use of rare metals, shorter sintering times, and a significantly simpler manufacturing process flow that avoids secondary processes such as heat treatment, reducing overall CO2 emissions.

Proposed applications : Transmission parts, 4WD actuator cam components, EV gears, parking systems

1. Advantages of Our Nickel Free Material

We have developed a high-strength, nickel-free material that incorporates completely alloyed Fe-Cr powder, giving it excellent hardenability.

2. Sinter-Hardening Technology

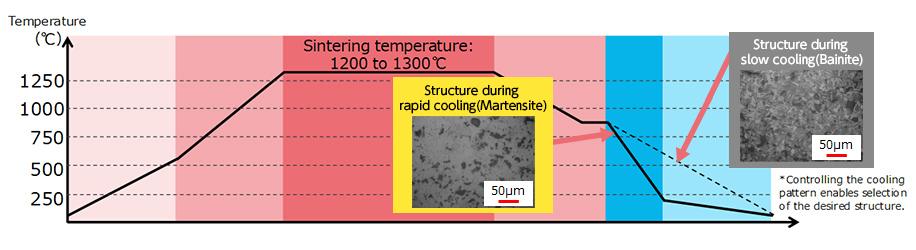

Sinter-hardening technology utilizes a dedicated sintering furnace with a specialized rapid-cooling zone to have products undergo sintering and hardening within the same production process.

Developed Advantages

1. The use of completely alloyed powder reduces the time necessary for diffusion, resulting in a shorter sintering time.

2. By using Fe-Cr powder with excellent hardenability, products can be hardened during the cooling phase of the sintering process by undergoing rapid cooling.

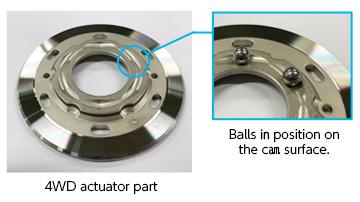

Application Example: 4WD Actuator Parts

Controlled Characteristics

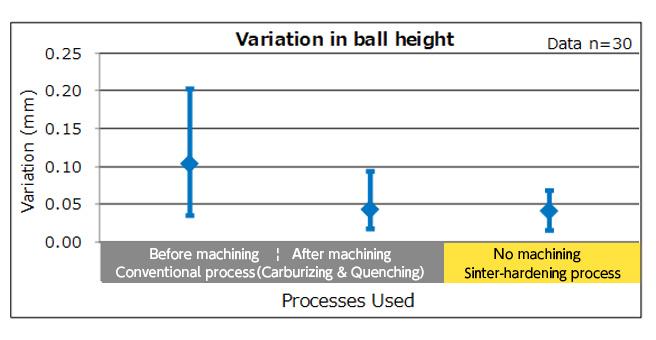

- Height variation between 6 balls as placed in position on the cam surface

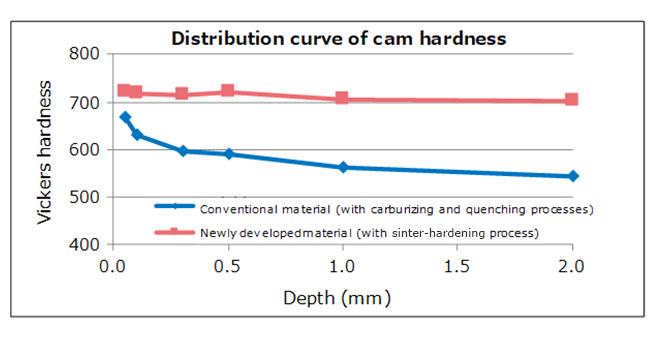

- Hardness of the cam surface (to ensure proper ball sliding motion)