Preventing Environmental Pollution

For basic views, structure, and targets, please refer to Environmental Management.

For performance data for environmental indicators, please refer to the CSR Book (ESG Data).

Initiatives and Results

Chemical Substance Management

The Sumitomo Electric Group is committed to properly managing chemical substances contained in its products, communicating information on chemical substances throughout the supply chain, properly managing chemical substances used in manufacturing at its factories, and reducing the amount of harmful chemical substances released into the environment, with the aim of complying with laws and regulations, earning the trust of its customers and consumers, protecting the health and safety of its employees, and contributing to environmental protection.

<Management of chemicals in products>

At the Group, the Committee on the Management of Chemicals in Products has been established to provide respective Divisions with information on laws and regulations as well as support to ensure compliance.

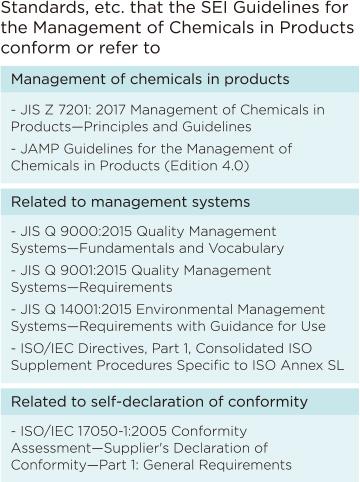

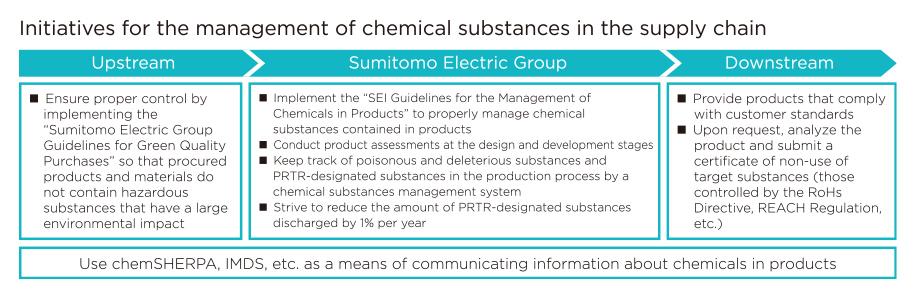

The Group is committed to properly managing chemicals in products by formulating and implementing the “SEI Guidelines for the Management of Chemicals in Products,” which is established based on JIS Z7201, Management of Chemicals in Products Principles and Guidelines. Also, we ensure that our products do not contain hazardous substances that have a large environmental impact, through measures such as establishing the “Sumitomo Electric Group Standards for Chemical Substance Management” and applying the “Sumitomo Electric Guidelines for Green Quality Purchases,” which is formulated for suppliers based on the above Standards, and conducting product assessments at the design and development stages.

Regarding sharing information on chemical substances throughout the supply chain, we proactively use the standards schemes across industries, chemSHERPA* and IMDS*, to alleviate the burden of information sharing among companies.

In addition, we audit our Divisions and aliates regarding the management of chemicals in products to improve and refine our management system.

● Measures for compliance with RoHS Directive and REACH Regulation

The Group promotes the use of alternatives to the substances restricted by the European RoHS Directive* and has replaced such substances to meet customer requirements for products that do not contain such restricted substances. Meanwhile, we work to ensure compliance with the REACH Regulation*, including the provision of information on SVHC* contained in products. Furthermore, to promptly deal with the regulations of other countries that are becoming stricter every year, we collect regulatory information from Europe, the US, China, Southeast Asia, and other countries and share it across the Group.

*chemSHERPA: A trademark or registered trademark of the IPPAN SHADAN HOUJIN SANGYO KANKYO KANRI KYOKAI (JAPAN ENVIRONMENTAL MANAGEMENT ASSOCIATION FOR INDUSTRY)

*IMDS (International Material Data System): A web-based database used by the automotive industry to communicate information about chemical substances in materials used in products

*RoHS Directive: Abbreviation for Restriction of the use of certain Hazardous Substances, and an EU Directive on the restriction of the use of Certain Hazardous Substances in electronic and electrical equipment

*REACH Regulation: Abbreviation for Registration, Evaluation, Authorization and Restriction of Chemicals, and an EU regulation on chemicals aimed at protecting human health and the environment

*SVHC: Abbreviation for Substances of Very High Concern, and chemical substances designated by the EU as being of high concern for their hazardous properties

<Management of chemical substances used in factories>

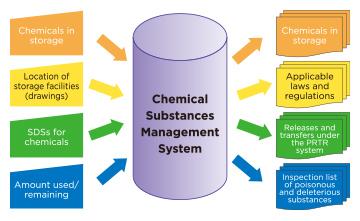

The Group has established a chemical substances management system that can be used across the Group, and in 2011 began managing poisonous and deleterious substances and PRTR-designated substances at its four Works in Osaka, Itami, Yokohama, and Ibaraki, as well as at its affiliates in Japan. Regarding all poisonous and deleterious substances, this system allows searching for companies that use these substances as well as their SDS (Safety Data Sheets). The system is also used to compile data for reporting under the PRTR system*.

*PRTR system: A Japanese law concerning the promotion of improved understanding and management of amounts of Specific Chemical Substances released into the environment

● Measures against PRTR-designated chemical substances

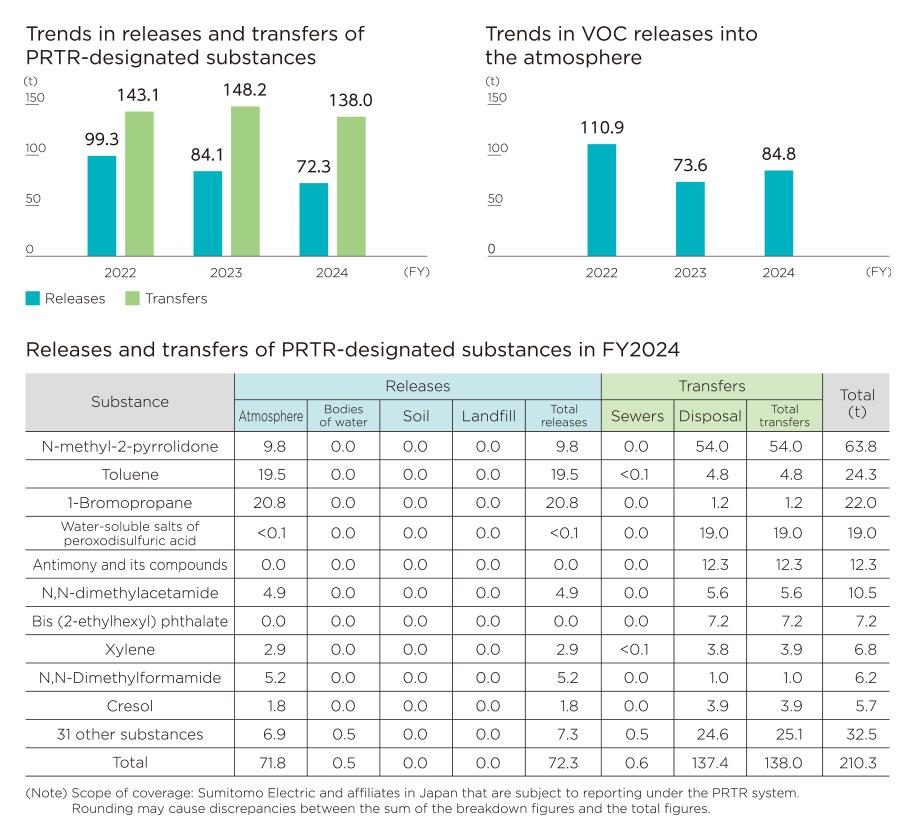

Starting in FY2015, we have been working to reduce releases of PRTR-designated chemical substances, targeting factories with an annual discharge amount of 1 ton or more, with the aim of an annual reduction in the release of such substances by 1%.

Under “Go for Green 2025,” we worked to reduce the amount of PRTR-designated chemical substances discharged and achieved a total of 72.3 tons in FY2024, a 27.2% reduction from the base year FY2022, significantly exceeding our target of 1%. Also, transfers including those to sewers and disposal were down by 6.8% from the previous fiscal year. Regarding chemical-specific discharge amounts, the atmospheric release of 1-Bromopropane stood at 20.8 tons, accounting for 29% of the total discharge amount, and we will continuously strive to reduce the substance.

● Measures against dioxins and asbestos

In the Group, the aluminum alloy manufacturing facility and the exhaust gas purification facility of Sumitomo Electric Toyama Co., Ltd. are subject to the Japanese Law Concerning Special Measures against Dioxins. The Group has confirmed that the amounts of such substances released from these facilities remain within the regulated standards. Currently, no products using asbestos are manufactured across the Group.

● Addressing organic fluorine compounds

On February 13 and March 21, 2025, Osaka Prefecture announced that groundwater contamination by organic fluorine compounds (PFOS and PFOA) had occurred in the Okubo Higashi district of Kumatori Town, Sennan District, and reported that levels exceeding the provisional guideline value had been detected on the premises of the Company’s subsidiary, Sumitomo Electric Fine Polymer, Inc.(SFP). Following this announcement and report by Osaka Prefecture, SFP has cooperated with the investigation by the prefecture and has confirmed the following regarding the seven wells in the SFP premises that were the subject of the investigation:

• The water levels at two wells used in the production process as water sources are below the provisional guideline values.

• Although values exceeding the provisional guideline values were detected in five wells not used in the production process, these wells are not used for drinking purposes.

In addition, through further investigations by SFP, the following have been confirmed:

• Water quality and soil have been surveyed to understand the actual situation, and no contamination exceeding the values announced by the prefecture has been confirmed so far.

• The use of raw materials that may have contained residual PFOA was ended by 2015.

• The levels of PFOA and PFOS in industrial wastewater discharged outside the facility

are below the provisional guideline values.

Based on the results of these investigations, SFP has once again become strongly aware of the importance of environmental conservation. As part of fulfilling its social responsibility, the company will continue to monitor wastewater for PFOA and PFOS levels, and will continuously take necessary measures in cooperation with local government officials to ensure the safety of local residents and other concerned parties.

Soil and Groundwater Conservation

At our three Works (Osaka, Itami, and Yokohama), where contamination was publicly announced in August 2001, and other sites in Japan where contamination has been confirmed through investigations to date, we implement cleanup measures on a continuous basis, including replacing soil, pumping and purifying groundwater, and suctioning soil gas. We also regularly monitor groundwater to ensure that contamination is not spreading outside our premises.

Environmental Incidents

If an incident/accident occurs at the Group that could lead to environmental pollution, such as exceeding wastewater standards or spilling of chemicals, we have a system in place to address such cases. In this system, the Environment Department will be notified of an environmental incident/accident by the relevant site or its responsible department and disseminate information about the cases throughout the company to alert employees. The relevant department then will take the lead in investigating the cause and considering countermeasures, and after verification of the results by the Environment Department, information on the cause of the environmental incident/accident, countermeasures, and points for attention will be distributed across the company.

Environmental incidents/accidents reported in FY2024 comprised three cases of wastewater exceeding standard values at affiliates in Japan and overseas and one case of discrepancies between the report submitted to the government and the actual facility condition at an overseas affiliate, which led to a fine being levied on the affiliate. All of the above cases of wastewater exceeding standard values were caused by domestic wastewater. In addition to the regular wastewater analyses that have been conducted, we will also carry out planned maintenance, such as cleaning and inspecting the pipes in the drainage route. To address the discrepancies described above, we plan to inspect the facilities for any other discrepancies between their actual condition and the drawings and to regularly check these facilities against the submitted drawings.

We will continuously strive to ensure the prevention of environmental pollution by keeping track of and understanding relevant laws and regulations in each region and ensuring regulatory compliance.

(Note) The data boundary is environmental facilities, such as wastewater treatment facilities, exhaust gas cleaning facilities, chemical tanks, and waste storage sites, and production equipment.