Environmental Management

Basic Views

The Sumitomo Electric Group recognizes that addressing global environmental issues including climate change is one of its key management issues, and continues to engage in environmental protection activities from a global perspective, in accordance with the Environmental Policy established in 1997.

Environmental Policy

Basic Philosophy

The Sumitomo Electric Group thinks it is primarily important to establish a society that is sustainable and has less environmental impact. While making continuous and steady efforts to promote our global environmental preservation activities, the Sumitomo Electric Group contributes to world people and society by providing products and services in “Environment & Energy,” “ Information & Communications,” "Electronics,” “ Automotive,” and“ Industrial Materials & Others” related business.

Action Guidelines

1. In order to promote environmental-oriented management in which the Sumitomo Electric Group considers environmental preservation activity is one of the most important issues for corporative management, the Group's action plan under this Environmental Policy will be established together with Group-wide environmental indicators and long term targets for environmental preservation. Reviewing environmental objectives and targets voluntarily, the Sumitomo Electric Group promotes continuous improvement on environmental performance.

・Reduce environmental impacts in manufacturing activities

①Proceed our efforts to prevent global warming

②Proceed our efforts to a circular economy

③Keep progress in environmental pollution prevention

④Promote biodiversity conservation

・Increase environmentally-conscious products and services for our customer demands

①Promote the development of products contributing to prevention of global warming

②Make best efforts toward phase out of harmful substances contained in the Sumitomo Electric Group's products

③Enforce carrying out product assessment

2. The Sumitomo Electric Group will fulfill and enforce environmental management system.

・We communicate the Sumitomo Electric Group's Environmental Policy to all people who work at the Sumitomo Electric Group and for the Sumitomo Electric Group while we provide educational programs on environmental preservation to improve their awareness.

・We conduct environmental audits, and we review and strengthen our environmental management system as well as environmental preservation activities.

3. The Sumitomo Electric Group will keep and improve compliance action.

・In addition to comply with relevant environmental legislation and regulations, and with other requirements to which the Sumitomo Electric Group subscribes, we set up the Sumitomo Electric Group's self-standards better than legislative ones and make efforts to maintain and improve them.

4. The Sumitomo Electric Group's Environmental Policy will be opened to the public upon request.

(Established in July 1997 Revised in June 2024)

Structure

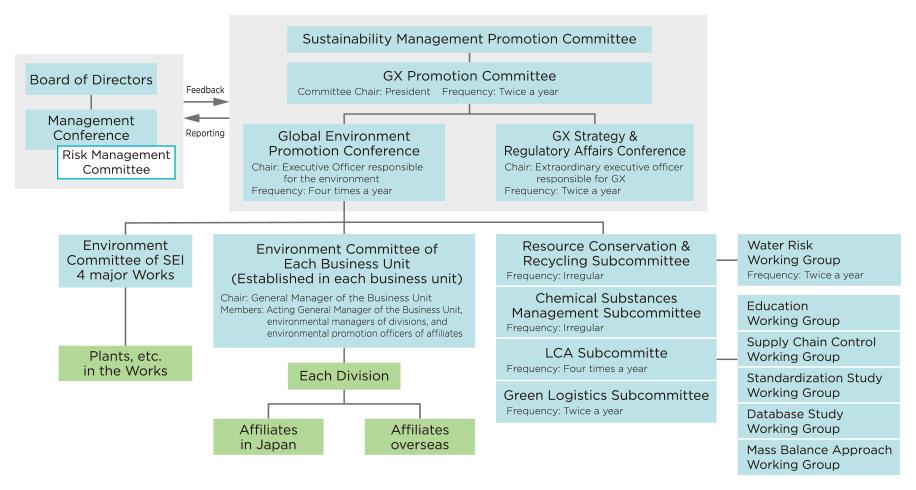

Structure to Promote Environmental Management

The Group has set forth the pursuit of “LIVING IN SAFETY AND COMFORT ON OUR GREEN PLANET” in its long-term vision, “2030 VISION,” and the goal of “Creating a Green Society through our Connecting and Supporting Technologies” in its “Mid-term Management Plan 2025,” emphasizing its contribution to the realization of a “green society.” The Group has been steadily engaged in environmental protection activities, including decarbonization, circular economy, and preventing environmental pollution. In order to further create and expand environmental value, respond quickly and appropriately to developments in the institutional environment in the global market, and strengthen the Group’s planning capabilities, the GX Promotion Committee chaired by the President was established in October 2024, under the Sustainability Management Promotion Committee. The GX Promotion Committee consists of the Global Environment Promotion Conference and the GX Strategy & Regulatory Aairs Conference. The Global Environment Promotion Conference oversees environmental protection activities on a global level, and discusses and deliberates specific targets and implementation strategies to address global environmental issues. The GX Strategy & Regulatory Aairs Conference oversees all GX-related planning activities throughout the Group.

Environmental Management System

The Group manages environmental protection activities systematically and is working on continuous improvement. To ensure steady implementation of environmental management, the Group is promoting the acquisition of external ISO 14001 certification of its environmental management system. As of March 2025, of 389 consolidated subsidiaries, 223 have obtained ISO 14001 certification, bringing the acquisition rate, including the Company, to 57%.

List of ISO 14001-certified companies (excluding listed subsidiaries)Major Environmental Risks and Measures

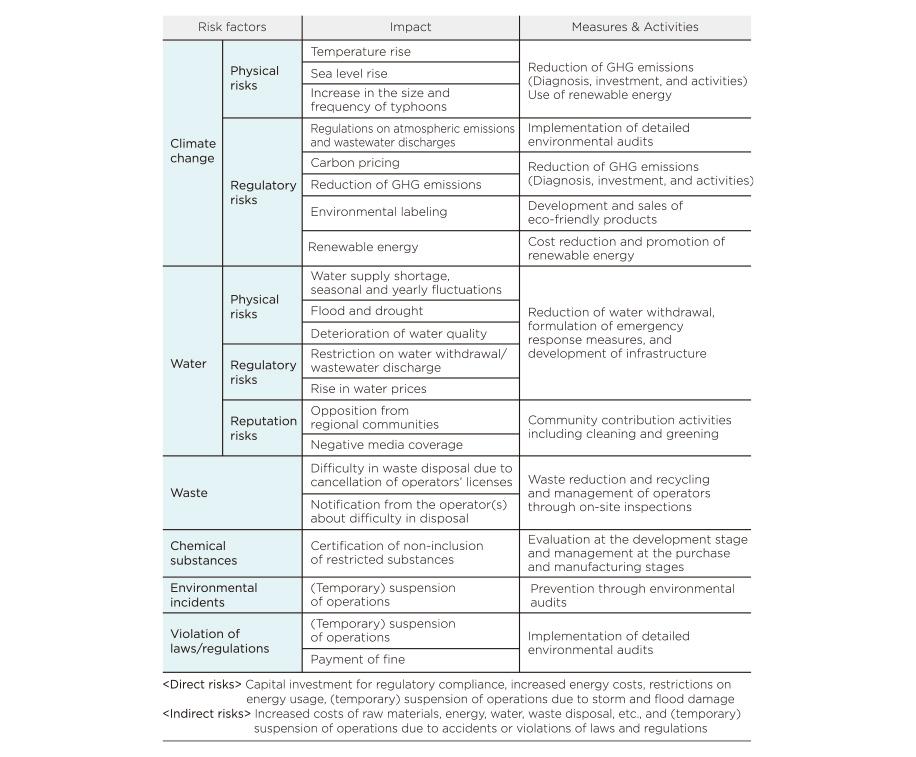

For top-priority issues such as environmental conservation, the Safety & Environment Division, under the leadership of the Risk Management Committee, which meets in conjunction with the Management Conference, plays a central role in formulating targets and action policies in cooperation with the relevant Corporate Staff Group, taking into consideration the deliberations of the Global Environment Promotion Conference. Based on the set targets and policies, each division sets its own targets and implements activities. To address risks including climate change, the Compliance & Risk Management Office takes the lead in promoting the formulation of business continuity plans (BCPs). While placing top priority on ensuring safety, the Group strives to minimize damage in the event of a disaster and ensure business continuity.

Risk Management System

Targets

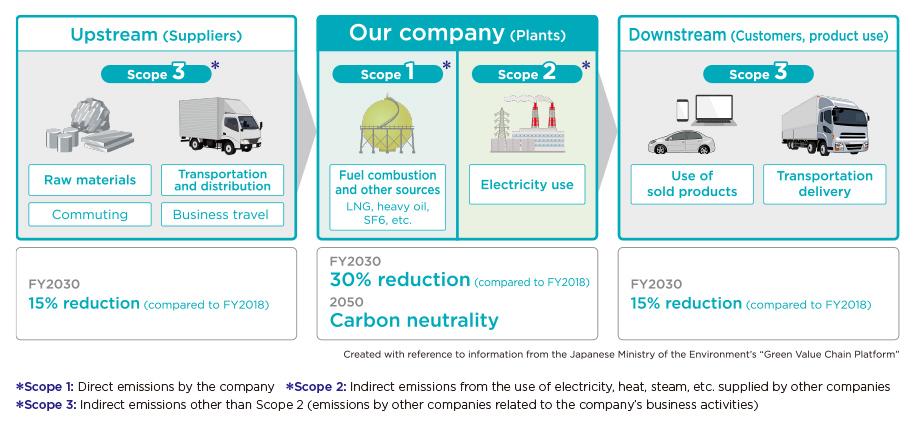

Targets for 2050

To achieve a “Greener Global Environment,” the Group’s long-term vision, “2030 Vision,” sets the following targets for decarbonization: a 30% reduction in Scope 1+2 emissions and a 15% reduction in Scope 3 emissions by 2030 compared to FY2018 levels, and achieving carbon neutrality in Scope 1+2 emissions by 2050. The “Mid-term Management Plan 2025,” which serves as a milestone on the way to the Vision, sets specific targets for various items, in addition to decarbonization, and activities are being implemented to achieve the set targets. The targets set in the “2030 VISION” and the “Mid-term Management Plan 2025” are for the entire Sumitomo Electric Group, including listed subsidiaries.

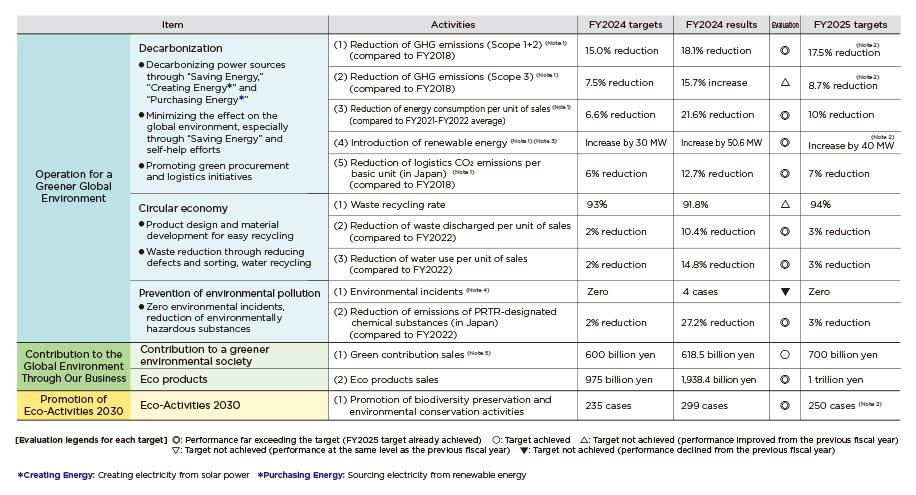

Targets in the “Mid-term Management Plan 2025”

The Group is working on “Go for Green 2025,” which sets out specific targets for 2025 as shown below. However, the table below does not include listed subsidiaries’ initiatives.

Initiatives and Results

Go for Green 2025

Taking global environmental activities, for which social demand is growing, in a broader sense, the Group is working on “Go for Green 2025” to contribute to realizing a green and environmentally friendly society through active implementation and expansion of its unique activities. “Go for Green 2025” consists of three key pillars: 1) Operation for a Greener Global Environment, 2) Contribution to the Global Environment Through Our Business, and 3) Promotion of Eco-Activities 2030.

The first pillar, “Operation for a Greener Global Environment” is primarily related to production activities, and involves decarbonization of the Group and supply chain, strengthening of LCA (Life Cycle Assessment) initiatives, promotion of circular economy, and prevention of environmental pollution.

The second pillar, “Contribution to the Global Environment Through Our Business” involves efforts to further promote the Group’s “Green Contribution” by setting a goal of expanding sales of products and services that promote a green society, in addition to “Eco products,” which are designed to reduce environmental impact through their own performance.

The third pillar, “Promotion of Eco-Activities 2030” is an initiative aimed at contributing to the preservation of biodiversity and environmental protection through daily eco-friendly activities at each business site such as tree planting, local nature conservation, and waste sorting to transform waste into valuable materials.

Holding Corporate Environmental Conference

The Group holds a Corporate Environmental Conference twice a year to share the targets and progress of “Go for Green 2025” and the results of each business unit’s activities. Participants in the conference include the President, officers in charge of the environment, and General Managers of the business units, and the participants engage in a lively exchange of opinions.

Furthermore, in an effort to invigorate “Go for Green 2025” activities, the Group also has established an internal commendation system to recognize outstanding environmental conservation activities. In FY2024, commendations were presented to six divisions and Group companies, including Sumitomo (SEI) Electronic Wire, Inc. (SEIW), which promoted energy saving in the production process through improvements at the production site.

Environmental Education

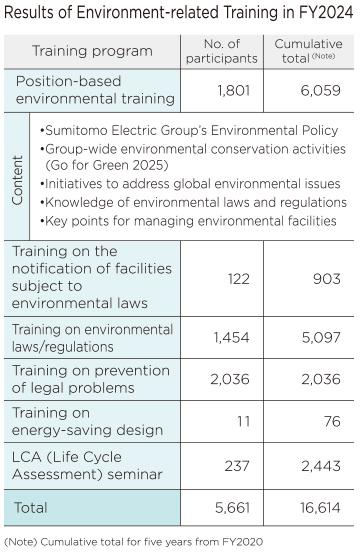

To realize environmental management, the Group works to raise individual employees’ environmental awareness and knowledge. As part of such efforts, the Group provides all employees with education on the Group’s environmental policy, Group-wide environmental conservation activities, and measures to address global environmental issues. New employees receive environmental education when they join the company. The attendance rate in FY2024 was 97%. (For those who could not attend the course, other opportunities are provided to allow them to receive environmental education, for example, when they are assigned to their respective departments.) In addition, position-based training is conducted to provide recurrent learning opportunities. The position-based training aims to equip employees with knowledge about the Group's initiatives and environmental laws and regulations, as well as to deepen their understanding of the important points in management of environment-related facilities from the perspective of preventing the leakage of hazardous substances. Specialized training on chemical substance management and other topics are also provided on a regular basis.

Environmental Audits

In addition to audits based on ISO 14001, the Group conducts environmental audits by the Environment Department to ensure thorough compliance with relevant laws and regulations and to reduce environmental impact. The environmental audits check (1) compliance with environmental laws and regulations and (2) maintenance and management of environment-related facilities and production equipment. The Group has set a policy of conducting, from FY2022 onwards, either an “environmental audit,” which checks both (1) and (2), or an “environmental law compliance inspection,” which checks only (1), every three years, depending on the magnitude of the potential environmental risks at each business site, such as whether or not hazardous substances are used.

Based on this policy, in FY2024, environmental audits were conducted at 18 sites both in Japan and overseas, and environmental law compliance inspections were conducted at 14 sites.

(1) Checking of compliance with environmental laws and regulations

Information on laws and regulations in the countries and regions where overseas sites are located is collected by using external services as needed, and compliance checks are carried out based on the collected information. The check items are not limited to compliance with laws and regulations but include the efforts to prevent omissions in reporting to government authorities, and the management status of wastewater quality based on voluntary standards that are stricter than regulatory values.

(2) Inspection of environment-related facilities and production equipment

From the perspective of preventing the leakage and spillage of hazardous substances, inspections are conducted to check the management status of environment-related facilities and equipment, including water quality facilities (chemical tanks, wastewater treatment facilities, etc.), ancillary facilities (pipes, etc.), and waste storage sites.

Participation in External Frameworks

The Group announced its support for the GX League Basic Concept* in December 2022, and joined the GX League in FY2024. The Group aims to realize a sustainable society by working on GX for society as a whole, not only through its corporate activities but also through the provision of green contribution products. The Group is also investing in the GX Acceleration Agency, which was established as a core institution to promote GX investment by the public and private sectors, and is supporting global efforts to realize GX.

*GX League: A forum for companies that are taking on the challenge of GX and aiming to achieve sustainable growth in the present and future society, with an eye to achieving carbon neutrality and social transformation by 2050. It facilitates collaboration among a group of companies working on similar initiatives, the government and academia. An initiative established by the Japanese Ministry of Economy, Trade and Industry.

Strengthening External Communication

In May 2025, the Group launched a special website introducing the Group's GX initiatives, including environmental protection activities.

The GX Special Website introduces the Group's products, technologies, and services that contribute to GX, as well as the Group's initiatives related to GX, such as those related to decarbonization, circular economy, and nature positivity.

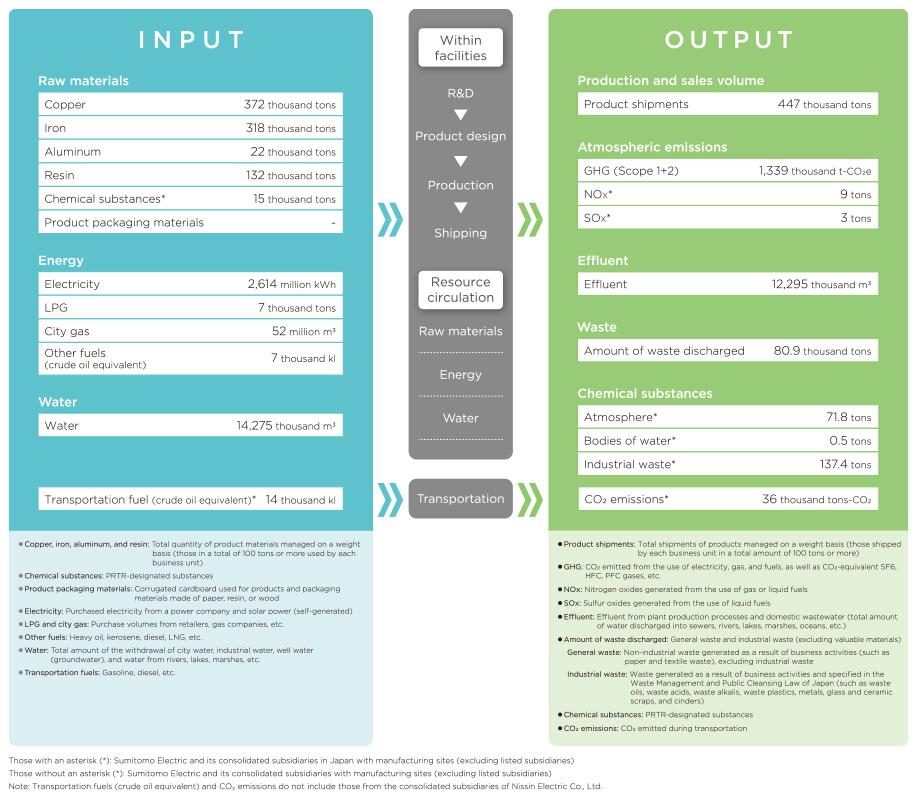

Environmental Impact Material Balance

The Group quantitatively assesses the environmental impact of its overall business activities and strives to reduce and properly manage such impact. We have compiled the results of our business activities in FY2024 in terms of the amount of energy and resources used in business activities (INPUT) and the products and substances that have an environmental impact resulting from those activities (OUTPUT).

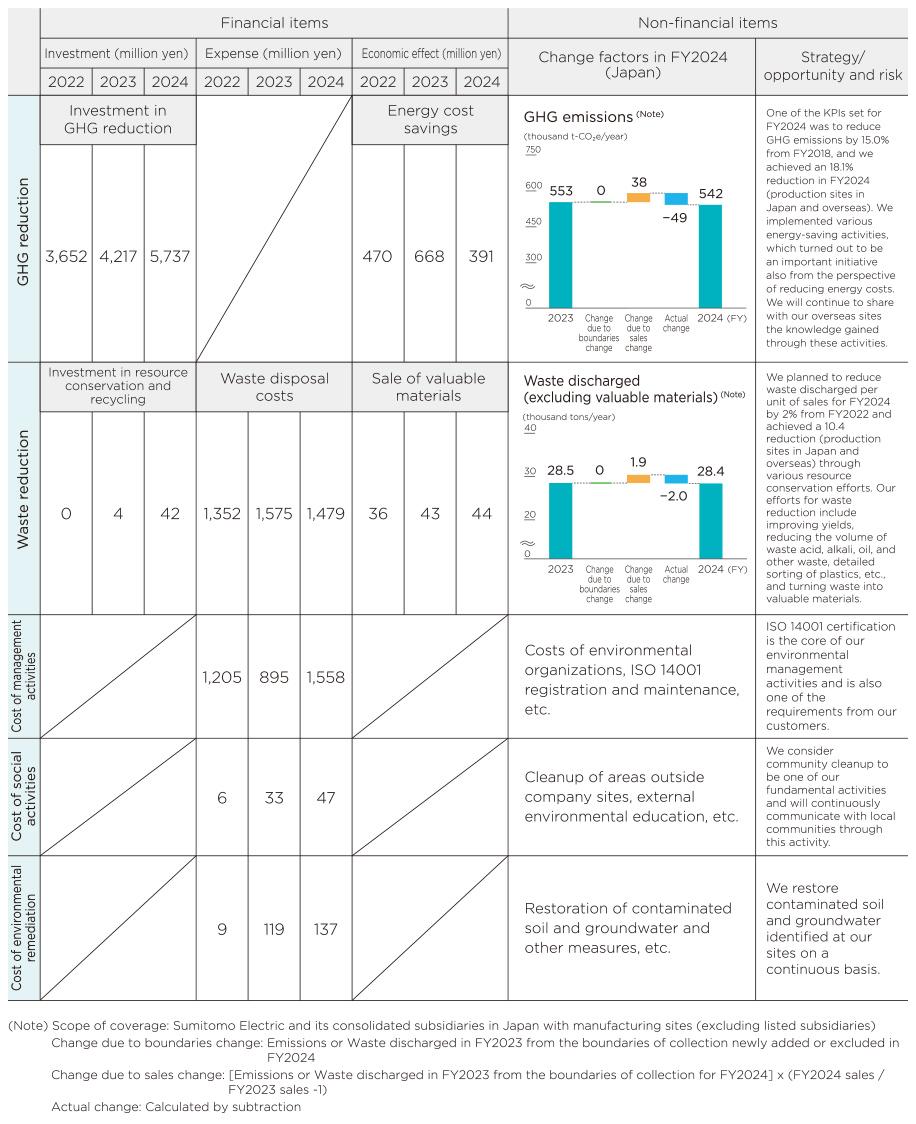

Environmental Accounting

The Group quantifies and analyzes the costs and economic effects of its environmental conservation efforts, such as measures to combat global warming. Since our CSR Report 2010, we have collected and disclosed environmental accounting data based on a new disclosure approach in reference to the concept of the Connected Reporting Framework (CRF)*

*Connected Reporting Framework (CRF): A reporting scheme recently developed in the U.K. that integrates financial and non-financial information in the disclosure.

Coverage

Environmental indicators cover the Sumitomo Electric Group’s manufacturing sites that have a data collection system in place. However, indicators related to the promotion of a circular economy cover non-manufacturing sites for which data can be collected. The Group’s calculations do not include the two listed subsidiaries and their consolidated subsidiaries because the Group’s action targets and promotion system/structure concerning the environment have not been shared with them.

As a representative example, when assessing the coverage rate of fiscal 2024 greenhouse gas (GHG) emissions (Scope 1+2), it was found that approximately 83% of the actual figures for the manufacturing sites were covered, meaning that the majority of emissions were reported.

Sumitomo Electric Group’s manufacturing sites: 1,619 thousand t-CO2e (284 companies)

Sumitomo Electric Group’s manufacturing sites (excluding the two listed subsidiaries and their consolidated subsidiaries): 1,339 thousand t-CO2e (180 companies*)

*Japan: 45 companies; Asia: 92 companies; Americas: 20 companies; Europe and others: 23 companies