1. Decarbonization

Sumitomo Electric Industries has set decarbonization goals to achieve carbon neutrality by 2050. By 2030, the company aims to reduce Scope 1+2 emissions* by 30.0% and Scope 3 emissions* by 15.0% compared to the 2018 levels. This commitment was recognized with SBTi certification in 2021.

In the optical fiber business, the company is actively working towards these goals by targeting a 15% reduction in Scope 1+2 emissions by 2024 compared to the 2018 levels. We are implementing energy-saving activities and other initiatives to contribute to the achievement of these targets. Additionally, we are focusing on reducing Scope 3 emissions by engaging with suppliers and customers.

*Scope 1: Direct greenhouse gas emissions from owned or controlled sources

Scope2 : Indirect greenhouse gas emissions from the generation of purchased electricity, steam, heating, and cooling consumed by the reporting company

*Scope 3: All other indirect emissions that occur in the value chain of the reporting company, both upstream and downstream

Internal Activities

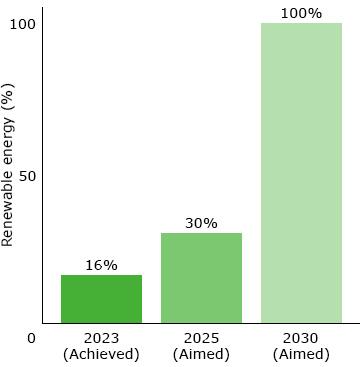

1. Renewable energy use

Producing optical fibers requires a substantial amount of energy, contributing to a significant environmental impact. As a result, implementing renewable energy sources proves to be highly effective in reducing CO2 emissions. In Sumitomo Electric's Optical Fiber and Cable division, 16% of renewable energy has already been switched across domestic facilities by 2023. Going forward, we will be dedicated to expanding the use of renewable energy, aiming to achieve a 30% introduction rate by 2025 and ultimately reaching 100% by 2030.

*Aggregate data from domestic facilities.

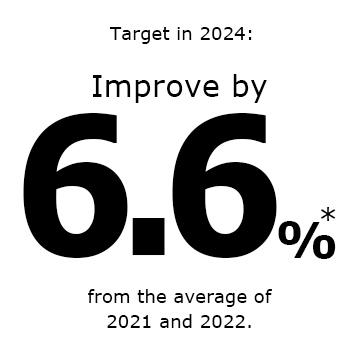

2. Improve manufacturing energy efficiency

Even with renewable energy, it remains important for us in the optical fiber business to recognize that it is still a valuable resource. We believe it is crucial to eliminate waste and use energy wisely. We have been continuously working towards minimizing electricity consumption in the manufacturing process by exploring more efficient manufacturing processes and equipment. In 2024, our goal is to improve energy intensity by 6.6% compared to the average of 2021-2022.

*Aggregate of domestic facilities, energy intensity decrease compared with the average in 2021-2022.

3. Continuing efforts in power conservation and energy efficiency

During manufacture of optical fibers, there are processes such as drawing and glass sintering that consume a significant amount of electricity. Although it may be minimal in comparison, we have been making small efforts to avoid unnecessary electricity usage. For example, we have switched to LED bulbs, which consume less power and have longer lifespans, and have also implemented motion sensors to conserve energy.

External Activities

4. Promoting green collaboration

Scope 1 and 2 emissions can be reduced through internal efforts, but reducing Scope 3 emissions requires collaboration throughout the entire supply chain, including end users, customers, distributors, raw material suppliers, and so on.

In Sumitomo Electric's optical fiber business, we not only focus on reducing our own CO2 emissions, but also propose products and initiatives that contribute to CO2 reduction for our customers and even the end-users. We are actively promoting Green Collaboration activities to co-create value throughout the entire supply chain.

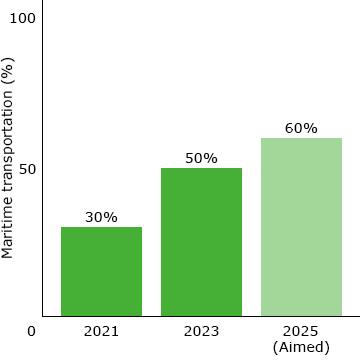

5. More use of maritime transportation

Japan is located at the eastern end of Asia-Pacific, which puts it at a disadvantage in terms of transporting goods to other parts of the world. However, by leveraging its status as an island nation and switching to maritime transport, it is expected to achieve a 90% reduction in CO2 emissions per kilometer of fiber compared to air transport. Customer cooperation is essential to utilize the long-haul maritime transport. We will continue our efforts to increase the ratio of maritime transport, while seeking the understanding and cooperation of many customers.

*Aggregate value at domestic main facilities

** Calculation based on the CO2 emission coefficient from the IDEA database, with the distance from Tokyo to Amsterdam Airport for air transport and from Tokyo to Rotterdam Port for maritime transport.

6. Utilizing inventory bases

Our company has inventory bases overseas, including in Europe. This is one of our initiatives to cover distances between various parts of the world and Japan, enabling shorter delivery times. By consolidating inventory replenishments and using maritime transportation, we reduce the use of airplanes and contribute to the reduction of CO2 emissions. Furthermore, our approach allows for Just-in-Time Delivery, providing the convenience of receiving goods promptly when needed and reducing the risk of holding inventory in-house. We are able to offer various benefits as a result.