2. Circular economy

In order to promote the circular economy, the Sumitomo Electric Group has set goals to improve the recycling rate (from 92% to 94%), reduce the amount of waste per unit (from 1 % to 3%), and reduce water resource usage (from 1% to 3%) compared to the FY2022.

In our optical fiber business, we have been working on reducing the rate of defective disposal through improved manufacturing processes and operations, minimizing the use of materials, and improving recycling rates by thoroughly sorting waste. We will continue to strive to not waste valuable resources and use them carefully, and to make ongoing efforts to contribute to the realization of a circular society.

1. Reducing waste intensity

In 2022, the CO2 emissions from waste generated by Sumitomo Electric's optical fibers were 0.03 kg-CO2/kmf (around 1% of the total). Our goal is to further reduce this by 2% by 2024. We will continue our efforts to reduce waste through manufacturing efficiency improvements, thorough waste sorting, and other waste reduction endeavors, aiming for zero emissions.

2. Examples of the effective use of industrial waste

The silica slurry generated during the preform manufacturing process of optical fiber, as well as the fiber scrap generated during the drawing process, can be transformed into road pavement materials and subbase materials. We collect and effectively utilize them as valuable resources, striving to reduce the high environmental burden of incineration and landfill waste.

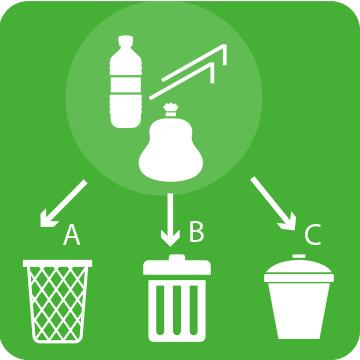

3. Strict sorting rules for recycling waste

Sumitomo Electric Industries has established detailed waste sorting rules and continues efforts to increase the use of resources and reduce waste volume as much as possible.

As an example, in our office in the Optical Fiber Manufacturing Division, we have installed collection boxes for five types of paper and two types of plastics. At the manufacturing site, we adhere to even stricter rules, and each employee has a high level of awareness towards the environment and complies with these rules.

4. Reuse and recycle of indirect materials

There are many indirect materials used in fiber manufacturing that are not part of the fiber itself. We have worked to establish reuse and recycling technologies for key indirect materials, such as the glass seed rod used in preform manufacturing, inert gases used in high-temperature processes, and certain packaging materials, as well as to improve the manufacturing process to reduce environmental impact. We are also currently addressing the challenge of recovering and reusing discarded raw materials (e.g. Germanium).

5. Helium recovery, reuse, and reduction of usage

Helium (He) is an important indirect material in optical fiber manufacturing, which involves high-temperature processes and requires excellent thermal conductivity. It is used in various fields, including medicine, but there is a risk of future depletion and its scarcity is increasing every year.

In our optical fiber business, we are actively working to reduce the use of He and implement helium recovery and recycling to prevent its depletion and minimize the environmental impact of manufacturing.

6. Reuse and recycling of packaging materials

While optical fibers themselves have a simple structure of silica glass and UV-curable resin, cables that use optical fibers often contain a variety of materials and complex structures. In addition, optical fibers can be used stably over a long period of time, making it difficult to recycle them as a resource at high frequency.

For this reason, we consider the recycling and reuse of packaging materials to be important. We are actively working to promote the collection, reuse and recycling of reels from our customers.