An Excellent Operation Rate of 99.8% Achieved by a Multinational Team

– Nemo Link Project –

The true value of DC XLPE cable proven in Europe

In Europe, which has been a global leader in tackling climate change, cross-border trade of electricity is already commonplace, and there is an international power transmission line using Sumitomo Electric high-voltage direct current (HVDC) cable.

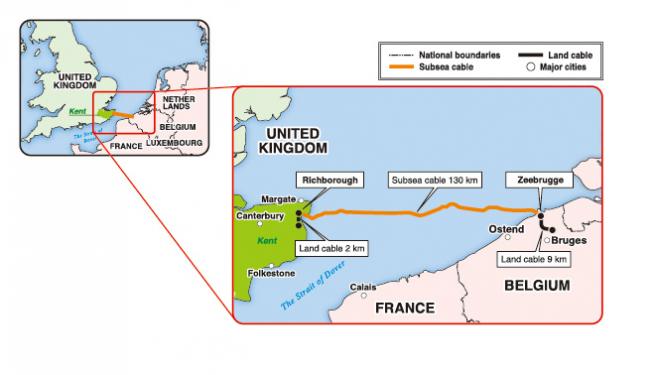

The UK-Belgium interconnector was built to help reduce CO2 emissions by utilizing renewable energy generated in both countries and to facilitate low-cost and stable power interconnection. In 2015, Sumitomo Electric signed a contract for this project with Nemo Link Limited, a joint venture between National Grid plc (UK) and Elia (Belgium), and took its first step into the European interconnector market. Sumitomo Electric was responsible for the manufacturing and installation of DC XLPE cable of a total length of approximately 140 km, including a submarine section of 130 km across the North Sea. The interconnector went into operation in February 2019, and its transmission voltage of 400 kV set a world record at that time. While the first issue of this e-magazine featured a story about receiving the order for this project, this issue introduces a story after that to the present.

The offshore installation started from the UK side in August 2017. The entire construction process had to be completed by the early winter of 2019 in order to start operating the facility as scheduled. To meet the tight schedule, Sumitomo Electric sent engineers with a wealth of experience. One of them is Takuya Miyazaki (Submarine Construction Group, Offshore Projects Construction Department, Power Cable Project Division), who directed the construction at the site as a member of the construction team.

“About 50% of troubles occur in the process of connecting cables. However, as long as they relate to connecting, we know how to manage them. This is our strength since we have accumulated a wealth of know-how. However, at the late stage of the construction, when it seemed to be proceeding as scheduled, an unexpected problem occurred. The cable installation work stopped 3 km before the cable landing point on the Belgium side. The planned landing point was a swimming beach. Since it was difficult for a large submarine cable laying ship to navigate the shallow sea, a special construction method and work ships that suit the terrain were necessary, but apparently the work method taken by the construction company in charge of this process was wrong,” says Miyazaki.

“The cable cannot be landed!”—A decision made to resolve the situation

It was a different kind of problem from the ones that had been able to be resolved by patiently dealing with them. While taking time to consider countermeasures, report the situation to Nemo Link, and discuss response with related departments in Japan, the swimming season came. On-site work was not possible during the season, and the time left for the construction team was becoming shorter and shorter. The testing of the cable had to be completed by early December, when the testing of the converter station was scheduled to begin. A tense atmosphere pervaded the team. “A construction delay crossed my mind,” reveals Miyazaki.

“In the end, we hastily arranged another construction company and tried landing operation several times by changing cable-laying ships. It was a tightrope walk, but the landing was finally completed in October 2018,” says Miyazaki.

However, some European members of the construction team disagreed with this response.

“In Europe, if a contract is not fulfilled by a subcontractor, it seems to be common to prioritize negotiation over anything else, and people think that it is unavoidable to suspend the construction during the negotiation and delay the schedule. However, we prioritized keeping the delivery schedule promised to Nemo Link and tried to solve the problem without suspending the construction. We gave top priority to doing what we should do for our customer. This Japanese style ‘customer-first principle’ may have seemed strange to European members,” says Miyazaki.

Miyazaki and his Japanese colleagues sincerely explained the “Sumitomo Electric way” to European members. Although they had different ideas and methods from each other, they shared professionalism and a common desire for the success of the project.

“The construction team consisted of twenty-some European members, mainly from the UK and Belgium, and three to four Japanese members. It may be more accurate to say that Japanese members acted as ‘coordinators’ who created an environment in which individual team members could perform their jobs at a high level, rather than ‘instructors’ or ‘leaders.’ Since we had built a relationship of trust with our European counterparts while keeping this in mind, they finally accepted the way we suggested,” says Miyazaki.

Transparency that strengthened the partnership

The landing of the submarine cable on the Belgian side was the biggest challenge for the project, but it resulted in increased confidence in Sumitomo Electric, says Mr. Bert Maes, the CEO of Nemolink Ltd.

“It was a very risky decision to change the subcontractor at the late stage of the construction, but Japanese members clearly explained why the problem had occurred and how they were dealing with it,” says Mr. Maes.

When Nemo Link was established as a joint venture between the UK and Belgium and began discussing the selection of contractors for this project, National Grid was reluctant to appoint a company that had not had any track record in Europe, while Elia was willing to use DC XLPE cable. An opportunity to resolve the disagreement between the two companies was the enthusiastic proposal from Sumitomo Electric: “Please visit Japan to see our manufacturing site.”

“We decided to leave the submarine section to Sumitomo Electric because we were convinced of its transparency in the event of a problem, not to mention its technical excellence,” says Mr. Maes.

He says that the final deciding factor was that Sumitomo Electric showed things as they were without hiding or exaggerating.

“This attitude was consistent throughout all processes, from manufacture to transportation and construction. Sumitomo Electric also showed great cooperation with Siemens Energy, a German company in charge of the converter station,” says Mr. Maes.

Great achievement of a 99.8% facility operation rate

While Sumitomo Electric was in charge of the HVDC cable, Siemens Energy was in charge of the converter station that converts transferred electricity from DC to AC and vice versa. The partnership between these two companies was a great contributor to the success of this project.

“The cable was not the only thing that was connected through this project,” says Mr. Joergen Kroemeke, General Manager of HVDC Project Execution at Siemens Energy, referring to another aspect of the project.

“The construction team was a multinational organization with members from five countries. Not only Japan and Europe, but also individual European countries have different backgrounds. A strong partnership was essential to achieve a common goal, and it was a challenge to find how to build it. Team members actively interacted with each other even during non-work hours by going on weekend trips with their families and going out for dinner. It was an invaluable opportunity to deepen our understanding of each other’s culture,” says Mr. Kroemeke.

The success of this project significantly strengthened the relationship between the two companies. Since then, as reliable partners, they have jointly worked on technical development and participated in various interconnection projects around the world.

In 2022, the UK-Belgium interconnector celebrated its fourth year of operation. With the tailwind of the increasing development of offshore wind farms, it is playing an important role in power infrastructure in the EU. Due to the impact of the COVID-19 pandemic, the members of Sumitomo Electric have had to abandon visiting the site to perform regular inspections in 2020. However, this winter, they received good news from Nemo Link: “The annual facility operation rate in 2021 was 99.8%, the highest in the past three years!” Such a high average also means Nemo Link's stable earnings from the facility. Sumitomo Electric DC XLPE cable is certainly demonstrating its true value in an environmentally advanced region.

NEXT

By Crossing Borders, HVDC XLPE Cable Brings the Future of Electricity to People Around the World.

(6)Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.