DC XLPE Cables Accelerate the Use of Renewable Energy

“DNA” of Developers Passed on to Date

Long-cherished DC XLPE cables

Power transmission equipment for sending and receiving electricity between countries or regions is called an interconnector. The global community, which has been moving toward a decarbonized society, aims to create a future where electricity is interchanged in a large area by using international and interregional grids consisting of interconnector networks. In line with these developments in the energy market, Sumitomo Electric has been awarded contracts for interconnector projects to manufacture and install DC XLPE cables.

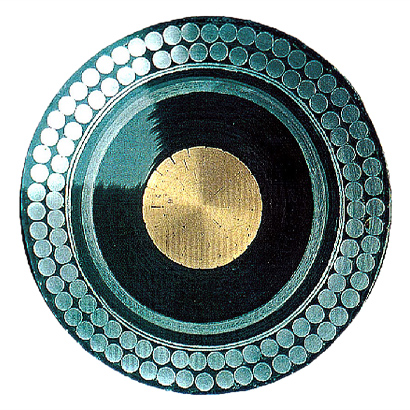

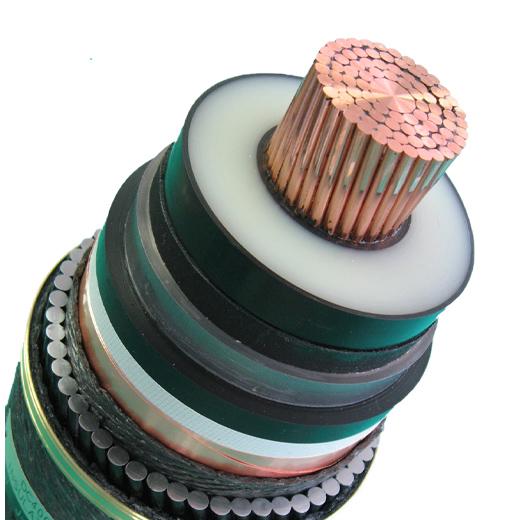

DC power transmission cables offer advantages in long-distance and large- capacity power transmission. DC XLPE cables, which use cross-linked polyethylene as an insulating material, have less environmental impact compared to that of oil-impregnated insulation cables. As a front runner, Sumitomo Electric became the first company in the world to achieve normal operation with the conductor temperature at 90°C, which is 20°C higher than that of conventional cables, and polarity reversal of power transmission voltage. This has achieved large-capacity power transmission, leading to the development of an innovative high-voltage DC (HVDC) cable capable of changing the voltage direction depending on the operation status of a DC interconnector (i.e., changing the direction of sending electric power by reversing the polarity of the positive and negative terminals).

Electric power companies around the world awaited the development of this power transmission cable. However, even after the advent of the 21st century, there were no reports that XLPE cables, which went into practical application and widespread use in the 1960s for alternating current (AC), were developed for direct current (DC). Against this backdrop, the Hokkaido- Honshu HVDC Link, a submarine cable installed by Sumitomo Electric in 2012, became the first HVDC power transmission line using XLPE cables.

How did Sumitomo Electric develop DC XLPE cables? Let’s take a look at the history of the development to fulfill the long-cherished dream.

■ Types of cables

| Types of insulation | Oil-impregnated insulation | Solid insulation | |

|---|---|---|---|

| OF cable | MI cable | XLPE cable | |

| Structure | Low-viscosity oil is pressurized into insulation paper and sealed. | High-viscosity oil is impregnated into insulation paper and sealed. |

An additive for preventing accumulation of electric charge is mixed in the cross-linked polyethylene. |

|

|

|

|

| Long distance | △ | ◎ |

◎ |

| Large capacity | ◎ | ○ |

◎ |

Challenging spirit passed on to date

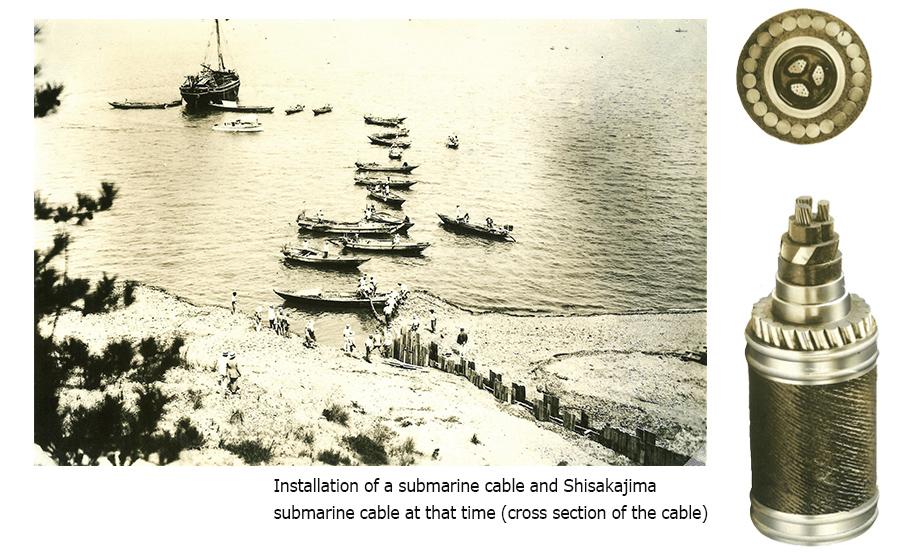

The history of Sumitomo Electric dates back to 1897, when Sumitomo Copper Rolling Works was founded to manufacture and sell copper sheets, rods, and wires using copper produced in the Besshi copper mine as the raw material. In 1905, the refinery was relocated to Shisakajima, an uninhabited island in the Seto Inland Sea. In 1922, the longest submarine cable in the world at that time (spanning 21 km) was completed between Niihama and Shisakajima to achieve stable supply of electric power. The persevering commitment to in- house manufacturing, no matter how much time it takes, is considered as the identity of Sumitomo Electric, underpinned by the challenging spirit, which has been passed on to date from Shisakajima. Sumitomo Electric has always taken the lead in the development of various power transmission cables.

The first DC power transmission cable in the world went into commercial operation in 1954 between Sweden and Gotland. Since then, oil-filled (OF) cables as well as mass impregnated (MI) cables, both of which consisted of wrapped and impregnated paper as an insulation material, were used as DC power transmission cables for many years. However, there was growing demand for insulation cables that did not pose the risk of oil leakage from the viewpoint of environmental protection in line with the growing awareness about environmental issues around the world.

Research on DC XLPE cables started in Japan in the latter half of the 1970s. At that time, long- term electrical tests were conducted to use AC XLPE cables, which were already in practical application, as DC XLPE cables without modification. However, it was found that AC XLPE cables could not be used for DC as is, due to the negative effect of the space charges (discussed later), which accumulated in the insulating material. Based on the results, Sumitomo Electric promoted the basic development of DC XLPE insulating material in 1984 in response to the development request from Electric Power Development Co., Ltd. (“J-POWER”).

Note) Sumitomo Electric established J-Power Systems Corporation (“JPS”) in 2001 by consolidating Hitachi Cable, Ltd. with the High Voltage Power Cable Div. In 2014, it made JPS a wholly owned subsidiary. In 2022, it succeeded JPS’s business related to manufacture of electric wires and cables.

Column

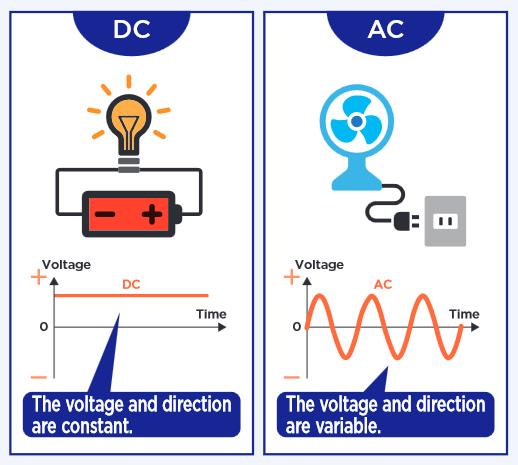

Basic knowledge of DC and AC

There are two types of electricity flow: DC and AC. In DC, electricity flows in one direction from the positive terminal to the negative terminal as in the case of a dry battery. In AC, electricity flows back and forth alternatingly like waves between the positive and negative terminals. Electricity generated at a power plant is delivered to homes in AC. Thus, most electricity used at home is AC.

Why is AC used dominantly? The reason dates back to the latter half of the 1880s, when Thomas Edison and Nikola Tesla, both of whom were inventors, clashed over which should be used for future electric power systems: DC or AC. Edison started DC power transmission for lightbulbs for the first time in the world. However, he faced problems in long-distance power transmission due to difficulties in voltage conversion, which could not be achieved by the technology at that time, and costs incurred by ultra- thick copper wires required for power transmission. Meanwhile, Tesla started AC power transmission. He achieved long-distance power transmission through the process of high-voltage power transmission, step-down, and power receiving by taking full advantage of the characteristics of AC, whose voltage was easy to change, on a scale far larger than that of Edison’s electric power system. In addition, AC was more suitable than DC for infrastructure because the equipment was less expensive and the maintenance cost was low. Thus, AC is used in most of the grids around the world, including Japan.

Today, electronic devices which require complicated control, such as PCs and smartphones, are operated by DC by using AC adapters, which convert AC to DC. Inverters, which are used in air conditioners and refrigerators, also convert AC to DC to achieve complicated control and energy conservation. DC is highly compatible with charging and is considered to be suitable for electric vehicles and charging equipment (i.e., suitable for renewable energy). A new era, which Edison might have ushered in, is finally beginning. DC may play a key role in the next- generation electric power system.

NEXT

Devotion to the Development of DC XLPE Cables

– An Inside Story on the Development of a Special Filler Material –

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.