Connecting Regions for Stable Supply of Electric Power

New Hokkaido-Honshu DC Seikan Tunnel Project

A major power outage that could have been avoided

In September 2018, the Hokkaido Eastern Iburi earthquake caused a large-scale power outage across the entire Hokkaido area.

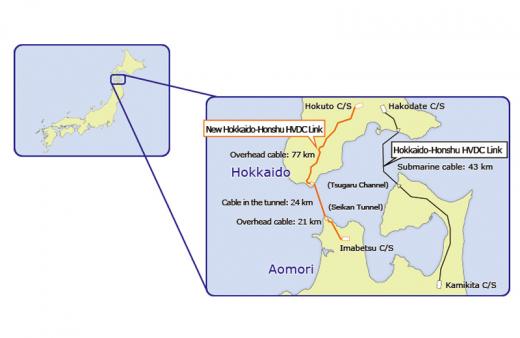

At that time, the test operation of the New Hokkaido-Honshu HVDC Link, whose entire construction process had been completed, was about to begin toward commencement of its commercial operation in March 2019. As discussed above, the Hokkaido- Honshu HDVC Link (submarine cable) was already in place between Hokkaido and Mainland Japan. Its operation was started by J-POWER in 1979. When the demand for electric power was high in Hokkaido, a stable supply was ensured through the electric power interchange from Mainland Japan. Subsequently, the second cable was installed in 1993, and the first cable that had deteriorated was replaced by the DC XLPE cable in 2012 (total power transmission capacity: 600 MW). The New Hokkaido-Honshu HVDC Link was designed to add the 300 MW capacity to constantly stabilize the electric power supply in Hokkaido. The New Hokkaido-Honshu DC Seikan Tunnel project was initiated to construct an underground power transmission line in the Seikan Tunnel. Tomoyuki Fukushima, who led the project as Director of the Trunk Network Work Center of Hokkaido Electric Power Co., Inc., explained how he felt at that time.

“Expansion of the interconnector had been planned previously to cope with the suspension of the Hokkaido- Honshu HDVC Link and large-scale repair in the future. Planned power outages following the Great East Japan Earthquake expedited efforts to enhance electric power interchange and expand interconnectors. The investigation and design of the New Hokkaido-Honshu HVDC Link started two months after the earthquake. The project aimed to start operation in five years after commencement of construction, which was short in terms of the construction period for an interconnector. I remember how I felt frustrated every time I was told ‘the power outages across Hokkaido could have been avoided if the New Hokkaido-Honshu HVDC Link had been in place,’” said Fukushima.

Taking on a challenge to cope with the severe tunnel environment

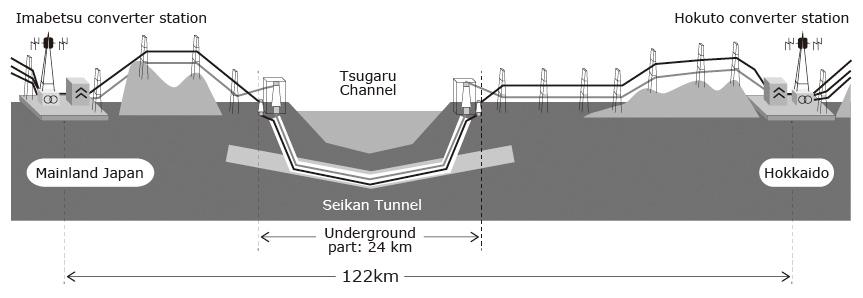

The cable was to be installed in the Seikan Tunnel. This was an unprecedented challenge for both Hokkaido Electric Power and Sumitomo Electric. Fukushima was the responsible person who formulated the basic plan. He admitted that he sometimes felt anxious about whether the project would be successful.

“We decided to install the cable in the Seikan Tunnel because the space in the tunnel was accessible to workers to visually check the cable after commencement of the operation. It was easy to conduct inspection and maintenance. It should be noted that the cable was to be installed in the service tunnel, which ran parallel with the main tunnel for the Shinkansen bullet train and was far smaller than the main tunnel. The installation space was near the ceiling, but both the installation space and work space were very small, so we had to make arrangements to adapt the design, construction method, and on-site management to the environment in the tunnel,” said Fukushima.

One year was spent to investigate the environment in the tunnel, formulate a route plan, and determine the equipment configuration. Sumitomo Electric participated in the project from the investigation phase. The situation was identified carefully to perform the construction work safely and reliably. Nevertheless, various problems, both major and minor ones, arose every day after commencement of the construction work.

“The submarine tunnel was completely dark, and humidity in the tunnel was always over 80%. In addition, a cloud of dust blew up due to the air pressure when Shinkansen bullet trains passed in the main tunnel. Despite such a construction environment, it was almost a miracle to complete the interconnector construction project in five years as planned, which usually takes eight to 10 years. It is difficult to explain in a word, but as I look back, the success was attributable to the efforts to discuss issues, which emerged one after another, with all the members and resolve them without compromise through concerted efforts. Above all, Sumitomo Electric’s engineering capabilities played a key role to deliver the 24 km-DC XLPE cable in a short period,” said Fukushima.

Growing demand for DC interconnectors in Japan

The large-scale power outage in 2018 stirred up discussions about the importance of interconnectors. The New Hokkaido-Honshu HVDC Link became the first interconnector in Japan to use a voltage-sourced AC-DC converter, which was just developed for HVDC in the 1990s. “DC XLPE cables, which can be used for any DC conversion methods, are derived from the high development and engineering capabilities of Sumitomo Electric. This was a valuable project for Sumitomo Electric,” said Kazutoshi Abe of the Power Cable Project Engineering Div. with confidence.

“The DC grid is like an expressway to interchange electricity in a large area, while the regional grid is a general road to send electricity to homes and companies. AC is used for the general road, so an AC-DC converter serves as an interchange of roads. There are two types of AC-DC converters: line- communicated converters and voltage- sourced converters. Sumitomo Electric’s DC XLPE cables can be used for both AC-DC conversion methods. The New Hokkaido-Honshu HVDC Link is the first project in Japan to apply the DC XLPE cable to the voltage-sourced AC-DC converter. The needs for similar specifications will grow in the field of interconnectors. Sumitomo Electric built a track record befitting the self- acknowledged top brand of DC power transmission cables,” said Abe.

One big step forward in the interconnector scheme

Having seen the completion of the New Hokkaido-Honshu HVDC Link, Fukushima is currently engaged in industrial promotion in Hokkaido at the Northern Advancement Center for Science & Technology (NOASTEC), to which he has been temporarily transferred.

“Zero Carbon Hokkaido is part of the Basic Policy on Economic and Fiscal Management and Reform promoted by the Japanese government. Hokkaido offers the biggest potential in Japan in terms of renewable energy, including offshore wind power. It will serve as a front runner when Japan aims to achieve carbon neutrality by 2050. Since renewable energy depends on the weather conditions, it requires a robust grid capable of coping with supply fluctuations. If interconnectors further expand in the future, Hokkaido will not just receive electric power from Mainland Japan through interchange; the electric power business to transmit renewable energy generated in Hokkaido to Mainland Japan will be further accelerated,” said Fukushima.

The New Hokkaido-Honshu HVDC Link is considered to have been a big step forward to achieve a scheme of connecting all of Japan through a large grid and sending electricity, which is generated at various locations and by various methods, to the consumption areas. Abe, who currently promotes an offshore wind power generation project in Japan, talked about his aspiration regarding the future of DC XLPE cables.

“To promote the widespread use of renewable energy, whose power generation amount is unstable, large- area interconnection must be ensured to stabilize the supply amount. The DC XLPE cables will increase their presence in interconnector projects in and outside Japan. I hope to gain experience and knowledge overseas and meet the growing demand in Japan,” said Abe.

In the paradigm shift in the history of energy, Sumitomo Electric will fulfill its role as a supporter of electric power companies by offering DC XLPE cables.

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.