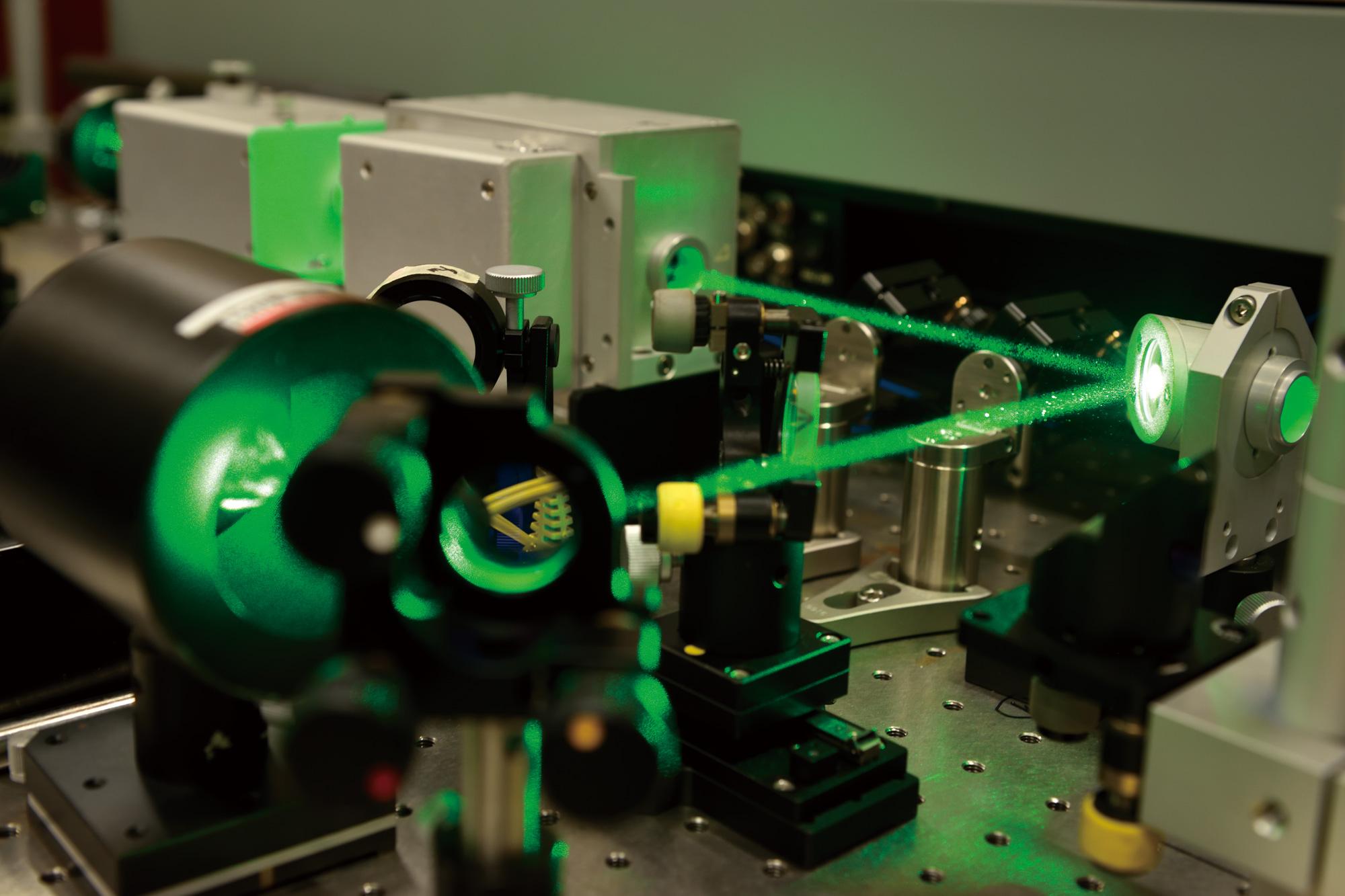

Active overseas operation and use of laser technology for production engineering

The Sumitomo Electric Group’s optical components lead manufacturing, meeting the demands of the times. Nozomi Ushijima, General Manager of the Advanced Materials Business Unit talks with hope about the future prospects of the Production Group.

“First of all, it is important to provide high value-added products. I believe that our proprietary products, which remain unmatched by our competitors, differentiate us from the competition. Germany and the United States are leading countries in laser technology. The technology has been flourishing recently in Taiwan, Korea and China. Sumitomo Electric has been actively supporting these markets. It has already shipped lenses to major laser processing machine manufacturers abroad.

We are also working on deploying our laser technology to production engineering within the Sumitomo Electric Group. For instance, materials for Sumitomo Electric’s tungstencarbide cutting tools and synthetic diamond tools are extremely hard and are difficult to machine. Notwithstanding their hardness, these materials can be shaped in a noncontact and highly flexible manner through the use of laser processing. Laser processing is a very useful technology in the drive to provide higher-performance cutting tools to society. Used actively, Sumitomo Electric’s optical components technology can be the driving force toward that goal.”

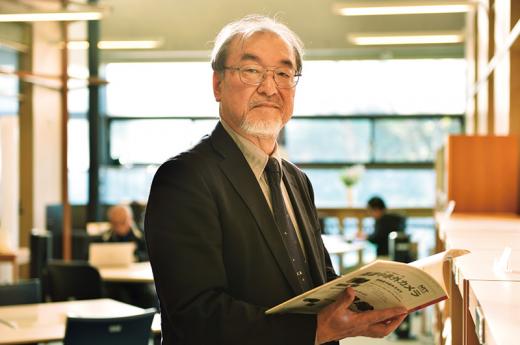

An interview with Prof. Akihiko Tsuboi, a leading figure in laser processing: “what is demanded is a technology that enables light to be controlled freely.”

The Graduate School for the Creation of New Photonics Industries is located beside Lake Hamana in Hamamatsu in Shizuoka Prefecture. The school opened in 2005 with the aim of using photonics science and technology to train human resources capable of creating innovative industries. Prof. Akihiko Tsuboi, Vice-President and Professor of the Graduate Course for the Creation of New Photonics Industries is a leading person who has worked for industrial application of laser processing for about 30 years since the early phases of CO2 lasers. He was interested in the potential of the laser when he was an employee at a major auto parts manufacturer. Subsequently, he founded a venture specializing in laser processing. Prof. Tsuboi helped many manufacturers to put the technology into practical use and led the progression and wide use of laser processing technology in Japan.

“Laser processing technology still has a long way to evolve. Seeds of novel ideas have emerged one after another, suggesting the technology’s profound potential,” says Prof. Tsuboi.

Presently, Prof. Tsuboi serves also as the Director of the Applied Laser and Innovative Technology Institute in the Tsuruga Comprehensive Research and Development Center of the Japan Atomic Energy Agency. He promotes research to apply laser processing to decontamination and structural cutting for reactor dismantling. This application makes the maximal use of the advantages of the laser, which are noncontact and high-power operation. It is also a challenge of extremely great social significance. The laser processing machine that is currently at the development stage for use in reactor dismantling uses the world’s highest 100 kW class ultra-high power laser, which was previously inconceivable. Prof. Tsuboi points out:

“Streamlining or productivity improvements cannot be made possible simply by introducing a laser. Lasers are not almighty. Initial investment for a laser is large. The wisdom of an engineer who has a good command of the technology is important. Given that an oscillator that emits laser beams is analogous to the engine of an automobile, lenses and other optical components are analogous to the drive unit. A car fails to move if the drive system is out of order. Similarly, I consider that the optical system is the core of laser processing. What is important is the manner in which the oscillator, optical components and processing conditions are combined in building the overall processing technology for each application.”

Prof. Tsuboi and the Sumitomo Electric Group have collaborated as business partners since the 1990s. For future laser processing, it is appropriate to ask what elements optical components need to have and what expectations exist for the Sumitomo Electric Group.

“Laser processing is employed in various fields. People at manufacturing worksites seek to carry out the desired processing in a flexible manner. For instance, they want to control the laser beam shape or divide the beams in the middle of processing a workpiece. Laser oscillators are important; at the same time, controlling the optical system plays a major role. Demand exists for the technology or product that can actively and freely control the beams; this involves knowing the beam profiles accurately and optimizing the energy distribution. Expectations are high for the Sumitomo Electric Group’s superb optics technology and product lines.”

Regarding future prospects, he continues: “The Sumitomo Electric Group has already built customer trust as an optical component manufacturer and is ahead of its competitors in engineering prowess. This is beyond doubt. The Group’s technologies will spark a great transformation and evolution in every aspect of laser processing.”

The Sumitomo Electric Group will continue to meet the challenges involved in exploring novel areas of optics for the laser to reach its full potential.

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.