Manufacturing Base

Source of sustainable growth, evolution and deepening of SEQCDD

As a manufacturing company, the Group considers the evolution and deepening of S (Safety), E (Environment), Q (Quality), C (Cost), D (Delivery), and D (R&D) to be the core of our business activities. As a source of sustainable corporate growth, while ensuring that each and every employee is fully aware of this, we are developing various measures in the areas of safety and health, environment, quality, production technology, and R&D.

Aim to be “the world's top safety company”

Promotion of safe working conditions

Sumitomo Electric has given top managerial priority to securing the health and safety of its employees as the core of its business growth, and aims to become the world's top safety company by promoting the creation of a culture where “Safety Comes First,” We are striving to eliminate all hazards and harmful factors, and to engage in ongoing safety and health activities with the participation of all employees.

In order to achieve this goal, we have established Safety Philosophy, Safety Principles, and Occupational Health and Safety Policy and incorporate the suggestions of our employees from the frontline perspective into the company's policies, and each fiscal year, we define the contents of our priority initiatives and items to be implemented. For details on our Safety Philosophy, Principles of Safety Activities, and Occupational Safety & Health Guidelines.

Toward the realization of a carbon-free and resource-saving society

Efforts to protect the global environment

The Group has established an environmental policy under the Corporate Environment Committee and is promoting the “Action ECO-22V” campaign as a mid-term target.

Reduction of greenhouse gas emissions

As part of its efforts to prevent global warming, the Group has shifted from a target of no increase in greenhouse gas emissions in FY2020 compared to FY2017 to a target of a 5% reduction in FY2022. Each production group is actively promoting energy conservation as a core component of its environmental activities, and a company-wide secretariat has been set up to promote energy conservation throughout the Group in cooperation with a specialist committee appointed for each division.

In addition to the above activities, our greenhouse gas emissions for fiscal 2020 decreased both domestically and overseas compared to fiscal 2017 due to the lower CO₂ emission factor for electricity this fiscal year, as well as the impact of the production decrease due to COVID-19 in the second half of the year, resulting in an overall reduction of 18.0%.

For details on the reduction targets for 2030 and 2050, please refer to “Initiatives Related to Global Environmental Issues” on page 47.

Eco-friendly products

In order to reduce the environmental impact of its business activities as well as to expand the offering of ecofriendly products, the Group has implemented a process from product evaluation to the calculation of the total amount of social contribution*1. By classifying products into stages such as eco mind products, eco-products, and anti-global warming products, we give feedback to new product development. Through this system, we strive to promote the development of eco-friendly products and their popularity in the market. Furthermore, among our eco-products, those that contribute to the reduction of CO₂ emissions during manufacturing and mainly during use by customers are registered as “anti-global warming products” and their reduction effects are calculated.

*1 Social contribution amount: Assumed amount of emissions to society.

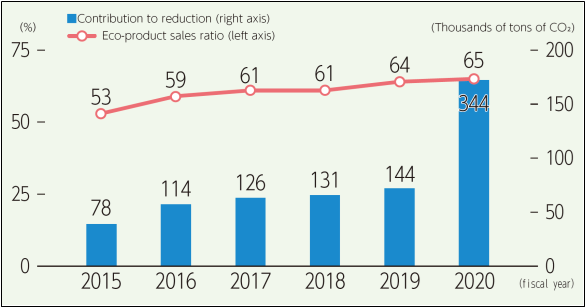

Eco-products sales ratio and contribution to CO₂ reduction

Calculation method

Eco-product sales ratio: Shipment value of products certified

as eco-products*2 / Total shipment value*2

*2 Shipment value: Shipment value of domestic manufacturing sector. Excluding the Electric Conductor Division, whose main purpose is to supply intermediate goods to the Group.

Responding to a resource-saving society

The entire Group is working as one to reduce the amount of industrial waste generated at our business sites. In addition to promoting the conversion of waste into valuable materials by sorting and searching for new applications, we are also working to reduce the number of rejected products at production sites as a fundamental part of manufacturing, reviewing the processes that generate defective products, and focusing on internal reutilization and reduction of waste that has been generated. In the “Action ECO-22V” campaign, we are working to achieve a 1% reduction in basic unit per year with FY2017 as the base year, and in FY2020 we are aiming to achieve a 19.9% reduction relative to FY2017.

We also take an active role in the promotion of recycling, and we promote the recycling of industrial waste whenever possible in order to effectively use resources to address social problems such as securing waste disposal sites and illegal dumping. Also, the entire Group is striving to reduce our zero emission rate*3. We also promote waste management overseas. Although the status of final disposal sites differs between Japan and overseas, the Group does not merely landfill its industrial waste at its overseas bases. Through activities such as recycling and converting to valuable resources as much as possible by sorting, we sustain proper waste management.

*3 Zero emission rate (%) = Simple incineration volume + landfill volume / industrial waste volume + general waste volume + valuable resources volume x 100

Global quality standards

Initiatives to Improve Quality and Reliability

Basic concepts and development of the QR-1 Campaign

The Sumitomo Electric Group aims to provide safe, reliable and high-quality products to customers in a stable manner as a fundamental principle based on customer oriented and quality-oriented policy. In order to continue to achieve this vision, we are strengthening our manufacturing capabilities, which are the base of our business, and systematizing our daily operation scheme, while steadily implementing and further improving the scheme.

Also, from 2002, we launched our QR-1 Campaign, with the slogan “Number one manufacturer in Quality and Reliability.” Through this campaign, we have made continuous efforts to enhance the awareness of quality among all employees through the three activities of “Own Process Quality Assurance Activities,” “Quality Management Education,” and “Global Quality Management System Audits.”

As part of the efforts to systematize the daily operation scheme, the Sumitomo Electric Group Quality Management Global Standards were established as a common framework to be applied to divisions throughout the Group in 2013. Each of our divisions makes continuous efforts to develop and strengthen its own quality assurance systems based on the standards so that customers can trust our products. In addition, we have established a company-wide cross sectional committee on quality in 2020 and began activities to strengthen the coordination and governance of the quality assurance departments of each division. We will continue to develop the QR-1 Campaign on a Group-wide basis.

For details on“ Own Process Quality Assurance Activities*4,” “Quality Management Education,” and“ Global Quality Management System Audits.”

*4 Own Process Quality Assurance Activities: The “Own Process Quality Assurance Activities,” which have been implemented since 2010 as part of the QR-1 Campaign, are a comprehensive approach to promoting “the prevention of defects in each process (occurrence prevention)” and “the prevention of defects from being passed on to subsequent processes (outflow prevention)” in manufacturing

Quality Compliance

For the sustainable development of the Company, it is absolutely fundamental to comply with laws, regulations, and rules, and to provide products that reliably satisfy the quality requirements of our customers. The Group is promoting measures to ensure rigorous quality compliance, including clarification of rules and expansion of education on quality irregularity prevention, and strengthening of our quality improper check function.

We have formulated the rules for the prevention of quality irregularities by using external examples of quality irregularities as a reference and incorporated them into the Sumitomo Electric Group Quality Management Global Standards, which are the Group’s basic rules related to quality, to clarify the rules and make them known to all employees. In terms of education, we implement annual compliance training for domestic managerial staff and Quality Management Education for employees at all levels, including education on quality irregularity prevention. As a function to check for quality irregularities, we are enhancing inspections related to the prevention of quality falsification in the Global Quality Management System Audits, which is a survey of actual conditions in each production group.

Also, there is a system in place for all divisions of the Group to conduct an annual “Self-evaluation of their main operations.” We have established a checklist for “quality falsification prevention,” and every year we make sure to verify that there are no quality falsification, that rules for quality falsification prevention have been established within each department, and that quality compliance training has been implemented.

Policy for CSR Procurement

The Group aims to contribute to the creation of a better society and environment through its business activities. For this reason, we ask our business partners, who directly or indirectly provide us with products and services, to work together with us on activities that contribute to social responsibility. As part of this, we are promoting initiatives for CSR in our procurement activities. In August 2010, we established the “Sumitomo Electric Group CSR Procurement Guidelines” based on the “Sumitomo Electric Group Corporate Principles” and the ”Charter of Corporate Behavior,” and in order to promote them more securely, we have incorporated the necessary items into our Basic Transaction Agreement. In fiscal 2020, these guidelines will be revised to address the issue of responsible mineral sourcing, and our business partners will be asked to comply. In order to promote CSR procurement, in addition to informing our business partners of these guidelines, we will also conduct surveys using the CSR Procurement Self-Evaluation Sheet to check the status of entrenchment, and promote improvement activities in cooperation with our business partners.

For details on the Sumitomo Electric Group CSR Procurement Guidelines.

R&D themes for future generations

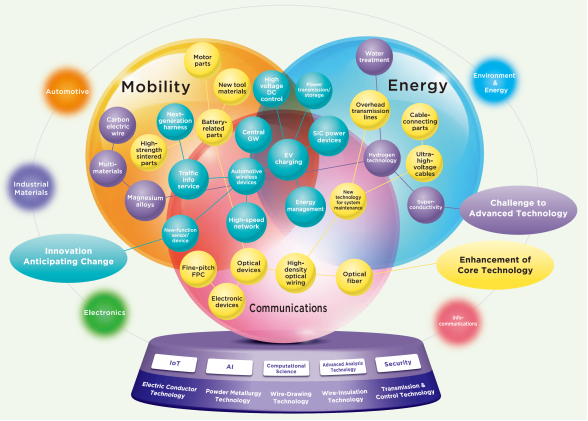

Further strengthening of our core technologies and responding to society through innovation

To respond to the new social and environmental needs represented by the SDGs, the R & D Group will take on the challenge of various transformations, including major changes in automobiles, the proliferation of renewable energy, and the use of big data. While aiming to grow our businesses in the areas of “Mobility,” “Energy,” and “Communications,” as well as the products and services that support them, we will contribute to the realization of a better society by leveraging the diversity of our businesses and technologies to create innovation. We will accelerate the development of new products and businesses by combining the core technologies we have cultivated over the years with advanced IoT, AI, computational science, analytical technology, and security. Furthermore, with an eye on the society of the future, we will challenge the development of innovative technologies that are expected to bring about major social changes, such as carbon wires, hydrogen energy, and innovative materials.

For details of our research and development system, as well as our development system and related technologies in each field.

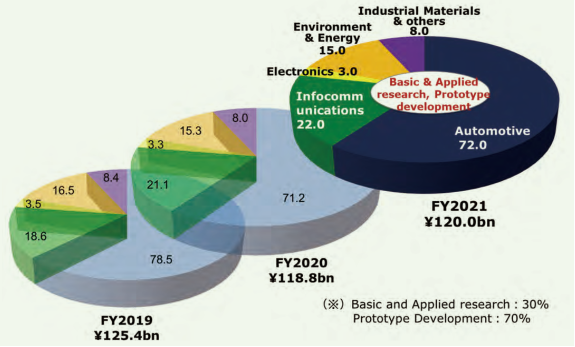

R&D expenses to support sustainable growth

Based on the principle that R&D is the engine of sustainable corporate development, we have focused on R&D activities without cutting R&D expenses, even when faced with a difficult business environment. Our R&D activities for fiscal year 2021 will be of high quality, focusing on priority areas such as proposal-based R&D activities with an eye on next-generation automobiles and product development related to next-generation infocommunications technologies. In terms of expenses, the Company plans to maximize efficiency to 120 billion yen.

R&D Expenses by Segment

A journal of technical papers “SEI Technical Review”

The Group first published a technical journal in 1933 to explain the content of its technologies. Currently, it is published twice a year as“ SEI Technical Review.” Back issues of this magazine, including those from 2008 onward, are available on our website, so please take a look.

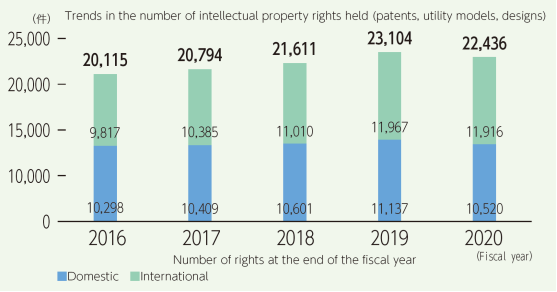

Protection of intellectual property rights for products and technologies

We are committed to protecting the intellectual property rights of the products and technologies we have developed over the years. The number of patents held is 10,520 in Japan and 11,916 outside Japan (as of the end of FY2020).