e-Axle

Based on our cultivated development technology and results we have gained by providing transmission parts for ICE vehicles, we are well-prepared to contribute to the evolution of the "e-Axles" for installation in BEV/HEV vehicles, for which demand will increase in the future.

-

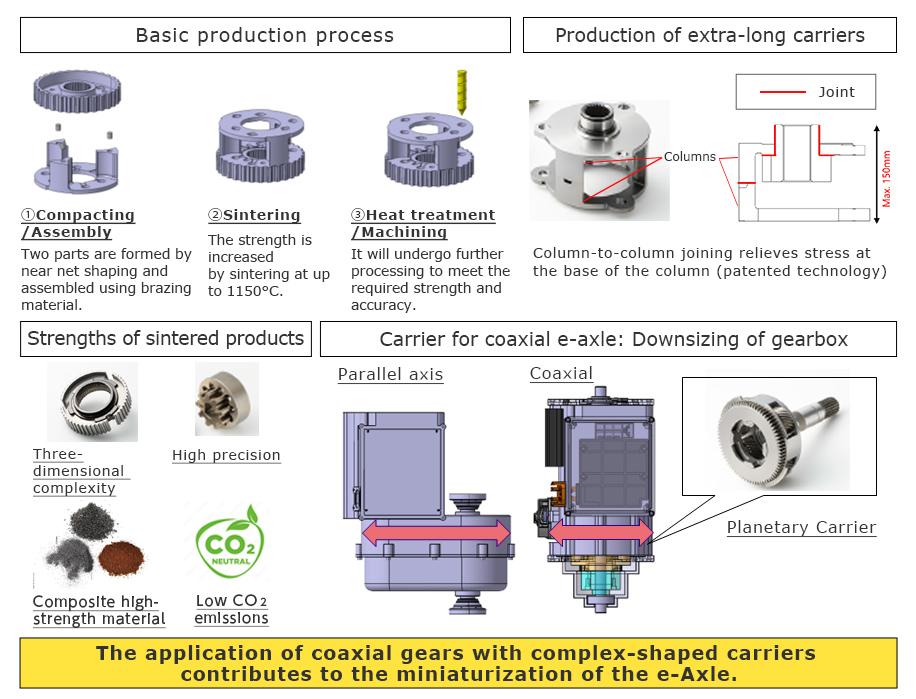

Sinter - joining technology

Our carriers for coaxial e-Axles contributes to downsizing the gearbox.

-

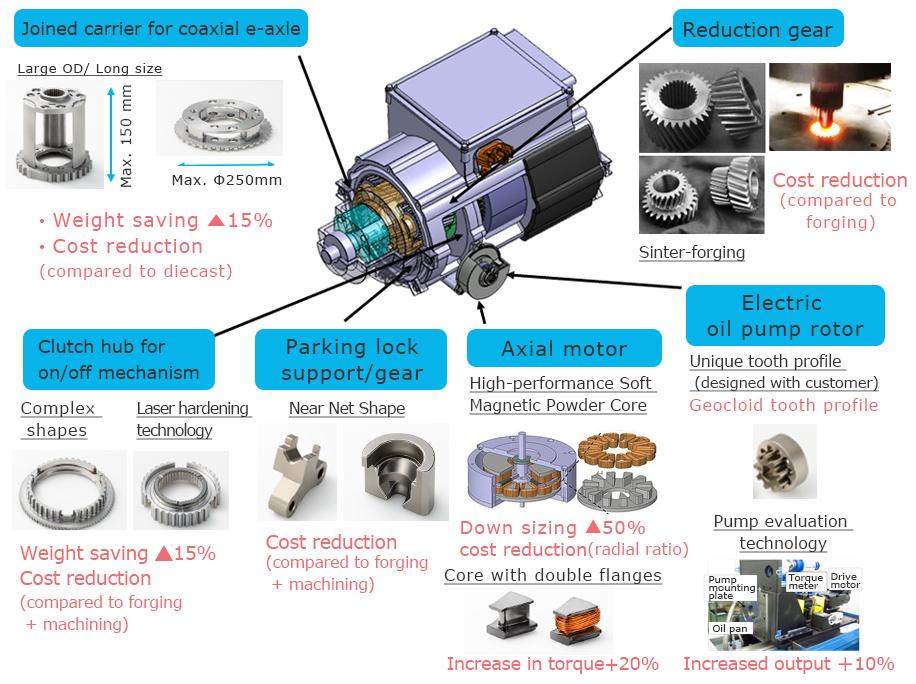

Sinter - forging technology

The reduction gear contributes to cost reduction by compacting the tooth shape.

-

Complex compacting technology

Our technology easily forms the complex shapes required for parking lock parts and clutch parts.

-

High-performance Soft Magnetic Powder Core

Axial motors incorporating Soft Magnetic Powder Cores allow for miniaturization of auxiliary equipment.

See what e-Axles incorporating our new technology and ideas can do for you.

Our proposals for e-Axle

Joined Carrier: Downsizing

of coaxial e-Axle