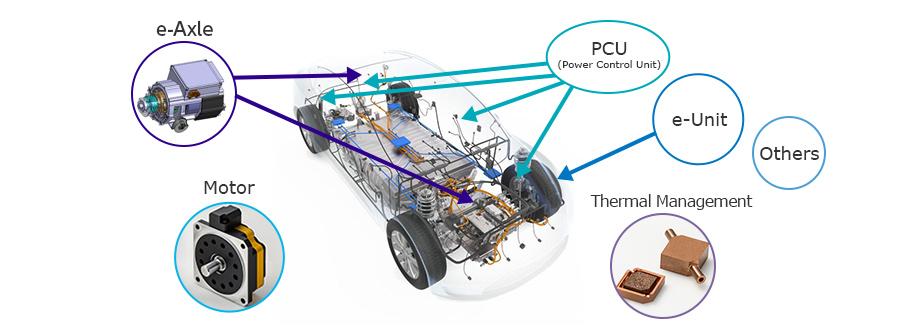

Mobility

As a partner that "connects" mobility, we contribute to electrification with "Miniaturization, light weight, high precision" technology.

For e-Axle

Planetary Carrier

Planetary gears are components of both transmissions in ICE(*) vehicles and coaxial reduction gears in e-axles. Its unique hollow shape with lateral windows is created without machining by utilizing sinter-joining technology.

We are adept at joining technology using brazing material, and we can respond to various shape needs with our high technological capabilities. We can consistently perform collaborative proposals for product shape design, strength analysis, prototype evaluation, and mass production in-house.

In addition, automated production lines allow up to supply of high-quality products at low prices.

Representative product : Carriers (*)ICE (Internal Combustion Engine car)

Parking lock parts

ICE vehicles transmissions and EV “e-Axle" have parts inside their gearboxes that lock the drive to prevent the wheels from rotating freely while parked.

The advantage of sintering is the high degree of design freedom that can be applied to complex shapes, enabling the creation of shapes that match the surrounding layout of the parking lock mechanism, contributing to weight reduction and the elimination of machining.

Representative products : Supports, brackets, parking gears, etc.

Clutch parts

Partial hardening (induction hardening, laser hardening) is applied to the end face of the sliding part of the synchro hub used in “e-Axle" disconnects in order to minimize the strain during heat treatment on the inner/outer splines. This allows for high precision.

Representative products : Sync hubs, keys, etc.

For Thermal Management

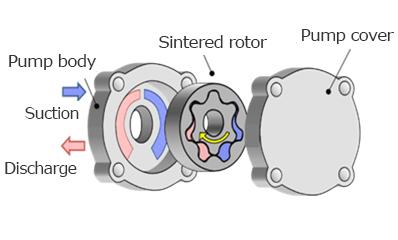

Oil pump parts

Oil pumps are essential for motor cooling and gearbox lubrication.

In the internal gear pump, oil is sucked in and discharged due to the change in volume between the internal teeth (outer) and external teeth (inner).

In sintering, high-quality yet inexpensive gears are commercialized by forming the smooth tooth profile using powder metallurgy tooling. In recent years, many sintered parts have been adopted for use in electric oil pumps installed in thermal management systems. Using our unique design technology, we provide pump parts that are small, yet highly efficient and quiet. We can also propose the optimum tooth profile and suction/discharge port shape according to the application. In addition, we also perform evaluation of the pump unit according to your request. Please feel free to contact us.

Representative product : Electric oil pump parts (outer rotor, inner rotor; internal gear type) Variable vane pump parts (cam ring/side plate/rotor)

For Motors

Soft Magnetic Powder Cores for Axial Motors

We are focusing on the “Axial motors”, which are significantly smaller and lighter* compared to general (radial motors). Based on customer's motor specifications, we can propose an electromagnetic design for the axial motor and supply the soft magnetic powder core (stator core), which is the core component of the axial motor.

Our Soft Magnetic Powder Core has excellent magnetic properties (low iron loss and high magnetic flux density) and flexibility in shape compared to general electrical magnetic laminated sheet cores, and has low CO2 emissions during manufacturing and excellent recyclability.

(*) Our design example : The overall length decreased by 58% and the weight by 44%.

For PCU

Soft Magnetic Powder Core for reactors

A reactor, one of the key components in a boost converter, has the function of increasing voltage by repeating the accumulation and release of magnetic energy. It is widely used for electric car battery voltage boosting, BEV in-vehicle chargers, quick chargers, and more. For our soft magnetic powder core, we have developed a material to accommodate a higher switching frequency, and have achieved further reduction in loss by independently adjusting the raw material composition.

For e-Unit

Electric power steering parts

Different types of electric power steering have been developed by various companies. In particular, we are well-versed in integrated production, including production including sheet crimping of guide racks, which are functional components.

We know that sintered parts will continue to be key components of steer-by-wire systems developed for use in future electrified vehicles.

Representative products : Guide racks, helical pulleys

VVT parts

There are two types of Variable Valve Timing (VVT) mechanisms: electric and hydraulic. The electric type has the advantage of quick response to control signals and the ability to be fixed at any angle. On the other hand, the hydraulic type has a simple structure, is highly reliable and is durable.

Adoption of powder metallurgy and its accompanying tooling enables mass production of VVT parts with high contour accuracy. Our strength is that we have a demonstrated history of mass producing products that achieve both high product strength and high contour accuracy by utilizing our unique heat treatment technology.

Representative products : Electric VVT parts: gear sprockets, gear slides / Hydraulic VVT parts: sprockets, rotors, housings

4WD parts

Many sintered parts are used in the 4WD transfer that demonstrates high performance. A ball cam mechanism used in a clutch that connects and disconnects torque requires high surface pressure and high strength. Accordingly, the use of special sinter hardening material negates the need for a heat treatment process, which allows for higher precision.

In addition, tooling used during the compacting process permit the formation of complex grooves on the end faces and internal and external splines.

Moreover, carriers used in planetary speed reduction mechanisms can be produced globally, depending on the braze joining technology required to meet our customer's needs.

Representative products : Cam main, cam pilot, apply cam, and carriers

Electric actuator reduction parts

We were one of the first to succeed in sintering planetary gears, sun gears and internal gears for planetary gear mechanisms, and have been mass-producing them for many years as parts for electric actuators such as starters.

What should be noted is that we have achieved low-cost manufacturing of high-quality planetary gears on an automated line that guarantees 100% tooth profile.

With our extensive material lineup, we are happy to respond to any and all requests for electric actuators parts meant for installation in electrified vehicles.

Representative products : Gears

Door mirror parts

Electric retractable door mirrors for automobiles generally have a drive gear for opening and closing the mirror.

Sintering technology allows door mirror parts such as helical gears and multi-stage parts to be manufactured at a low cost to near net shape.

Representative products : Gears, clutches

For Others

SUS/Stainless steel material

Generally, the machining cost of SUS/Stainless steel material is high due to its low machinability. However, we have achieved cost reduction by utilizing our expertise in complex shape compacting technology and eliminating the need for machining.

Representative products : O2 sensor boss, ABS sensor ring