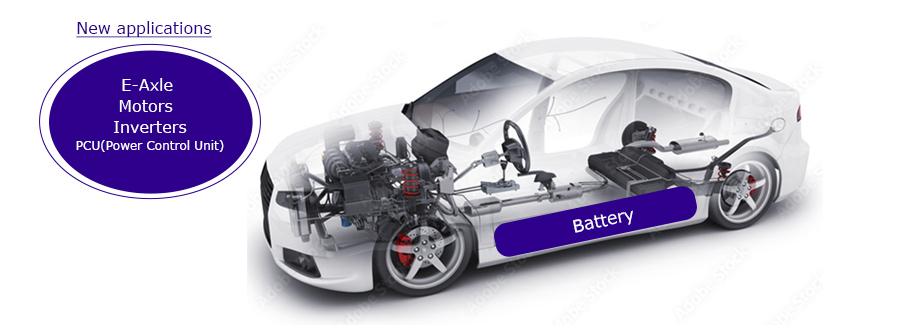

Thermal Management

As automobiles electrify, sintered parts are increasingly being incorporated into cooling mechanisms. Sintered parts contribute to the efficiency of thermal management systems owing to their advantages (porous, ferromagnetic, near net shape, etc.)

| Expected needs | Application | Our solution |

| High-efficiency cooling of electrical parts | Inverter PCU (Power Control Unit) Battery |

Improved cooling performance with metal porous body heat sink |

| High compressor output | Compressor | Near-net support for larger scrolls by applying powder metallurgy |

| High output and miniaturization of motors | Motor | Proposal of Axial motor |

| High pressure water pump | Water pump | Internal gear oil pump |

| Increased oil pump flow | Internal gear oil pump | Increased flow rate of oil pump rotor with unique tooth profile |

Examples of our technology applications

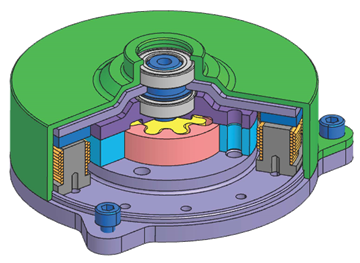

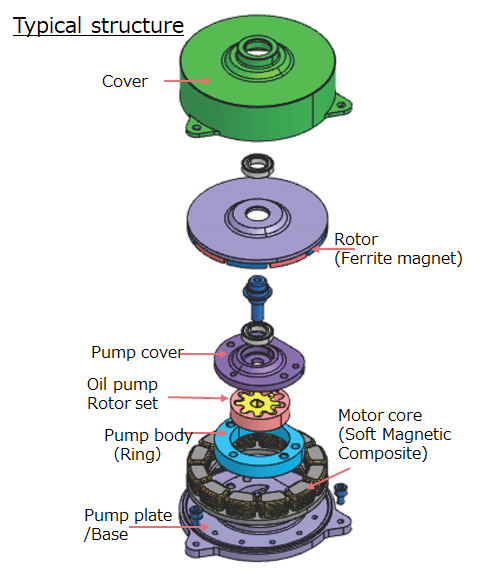

Axial Electric Pump (Electric Oil Pump using Axial Flux Motor)

The need for high efficiency of thermal management systems is increasing along with the electrification of automobiles.

In response to this, we have developed an axial electric pump that combines our technology, Axial Flux Motors, with an internal gear oil pump, to realize high efficiency, compactness and light weight of electric oil pumps.

We adopted a design that places the oil pump in the central space, which is a structural feature of the Axial Flux Motor, which made it possible to manufacture small, thin oil pumps.

Our development capabilities of motor and oil pumps allow us to propose electric oil pumps tailored to customers’ needs and provide evaluation support.

Proposed applications : Lubrication /Cooling /Hydraulic oil pumps

Axial Electric Pump

Adopted a design that places the oil pump inside the motor core

① 40% thinner than a radial motor pump.

② The motor has a self-cooling function.

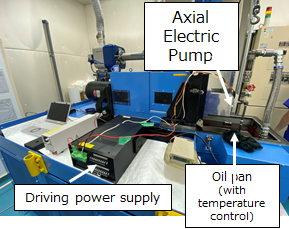

Development Support System of Axial Electric Pump

Design technology

We are able to offer in-house design for all components (including motors, housings, and oil pumps).

Evaluation technology

We are able to carry out the primary evaluation.

Evaluation items

- Discharge performance evaluation (40 to 120℃)

- Suction performance evaluation (-30 to 120℃)

- NV evaluation (Frequency analysis, etc.)

- Durability evaluation

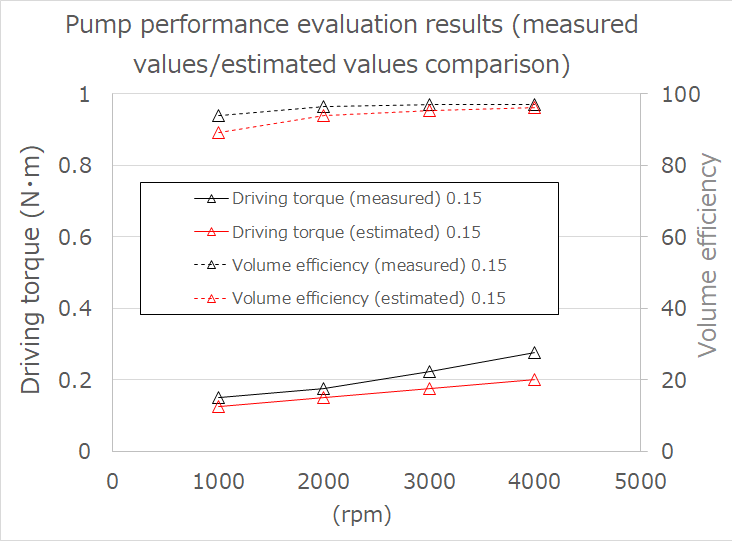

Evaluation results

(In-house model, oil temperature 80℃, oil pressure 0.15MPa, oil type ATF)