Technical Information

Applications and Characteristics

| Function | Applications | Material |

| Catalyst carrier |

|

Ni, Ni-Cr, Ni-Sn |

| Filtering |

|

Ni, Ni-Cr, Ni-Sn |

| High conductivity |

|

Ni, Ni-Cr, Ni-Sn |

| Electromagnetic shielding |

|

Ni |

Application

1」Catalyst Carrier

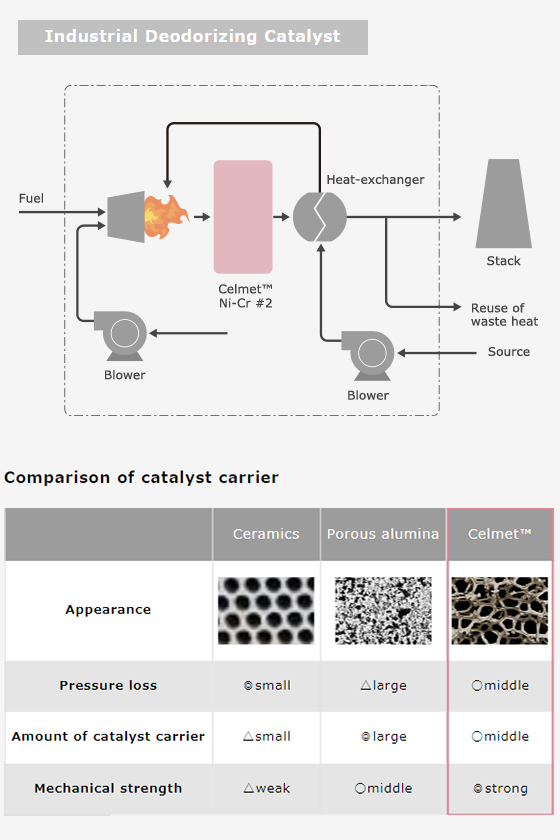

Celmet™ has been adopted as industrial deodorizing catalyst.

-

Improve performance

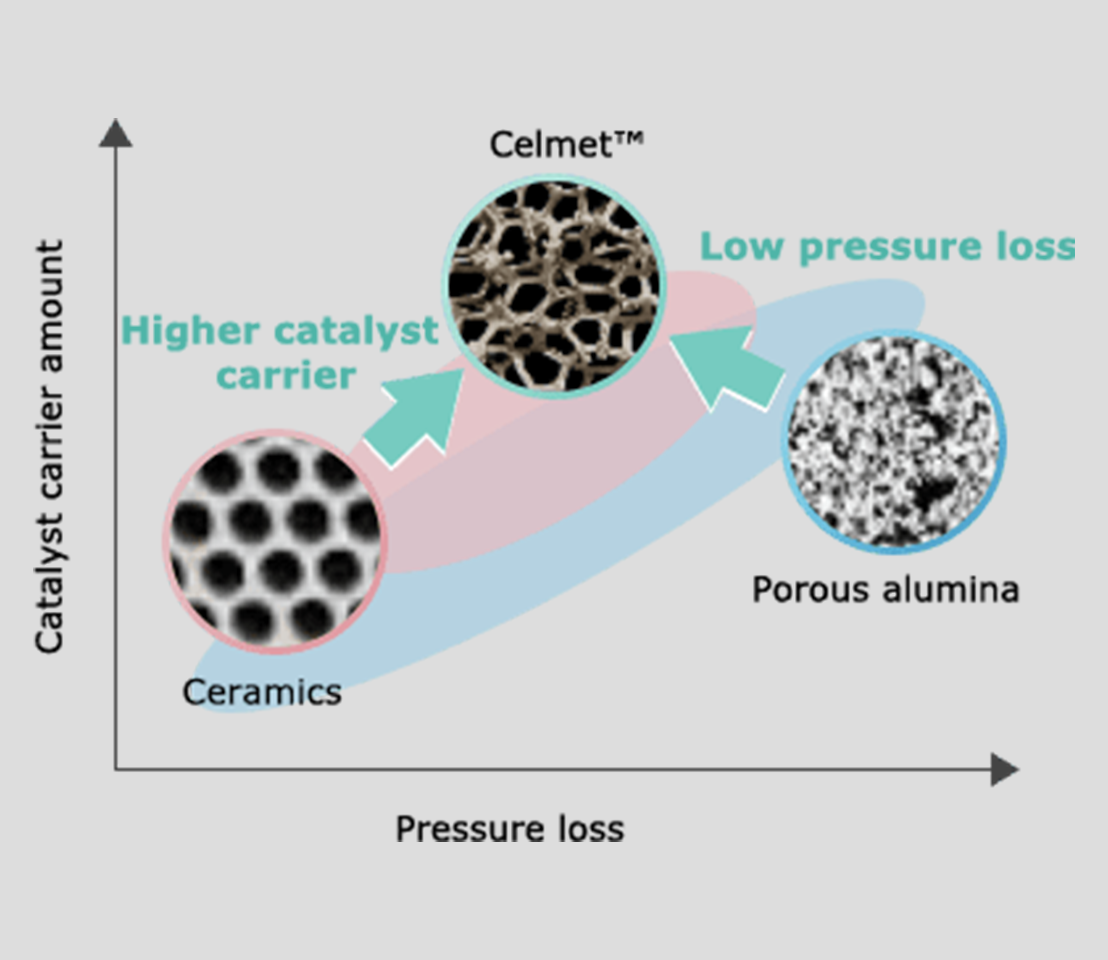

Compared to ceramics, the amount of catalyst carrier is increased due to its large surface area.

-

Low pressure loss

Compared to porous alumina, Celmet™ demonstrates a better balance between low pressure loss and high catalyst carrier.

-

Durability and strength

Compared to ceramic filter, Celmet™ is durable and can be used repeatedly.

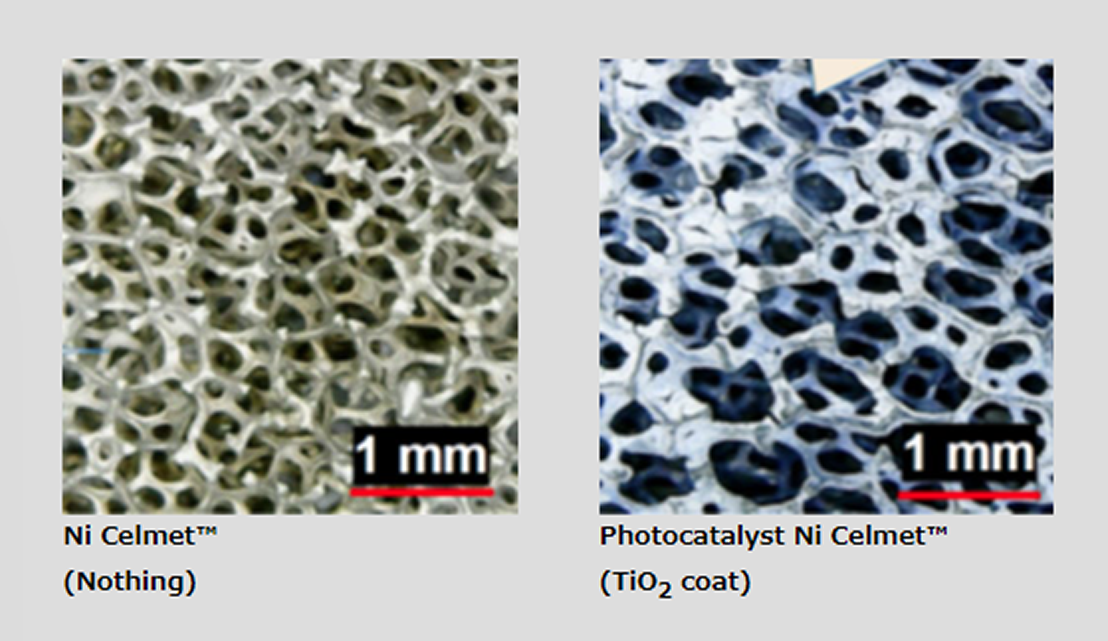

2」Photocatalyst Carrier

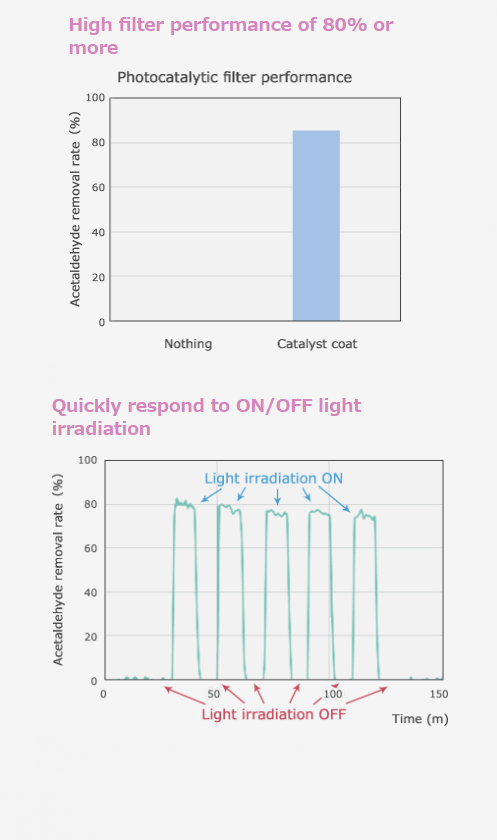

Celmet™ can work as air cleaner filter.

-

Removal rate of toxic substance is improved due to its large surface area of Celmet™

-

Quickly respond to light irradiation

-

Celmet™ as a metal has impact resistance and durability

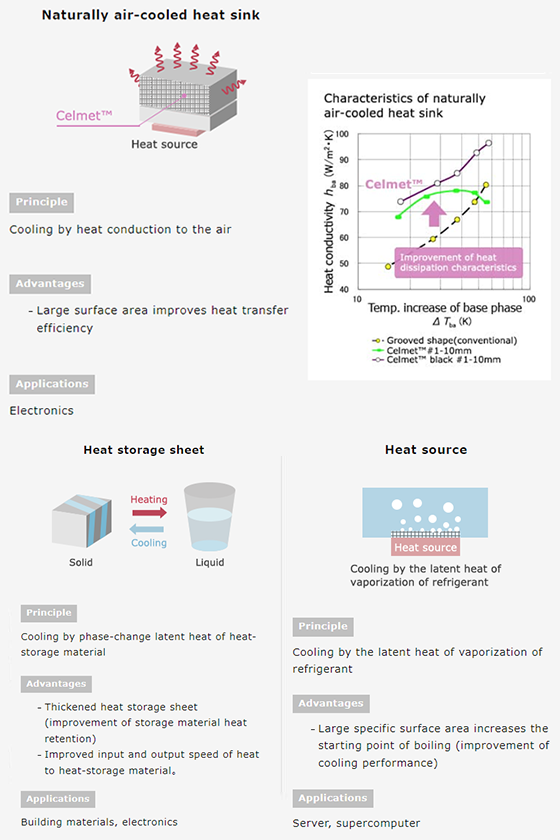

3」Heat Applications

Celmet™ has been considered as naturally air-cooled heat sink for automotive.

-

High performance

Miniaturization by improved cooling performance

-

Materials

Ni

-

Naturally air-cooled heat sink

-

Heat storage sheet (filling the heat-storage material)

-

ebullient cooling (the starting point of boiling)

-

electrical heating (Ni-Cr)

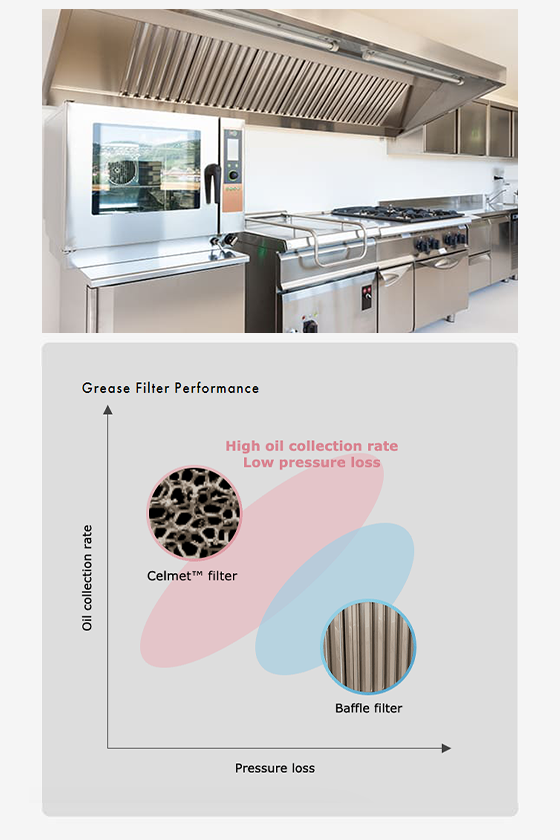

4」Grease Filter

Celmet™ has been adopted in restaurants and commercial facilities.

-

Compared to baffle filter, Celmet™ has higher collection performance due to its large surface area.

-

The material (nickel) can be repeatedly used by alkaline washing.

-

Compared to metal fiber or ceramic, Celmet™ has less chipping and mechanical degradation, improving safety.

-

Compared to stainless steel baffle filter, Celmet™ has better fireproof performance due to lower thermal conductivity.

-

The weight is one-third of baffle filter.

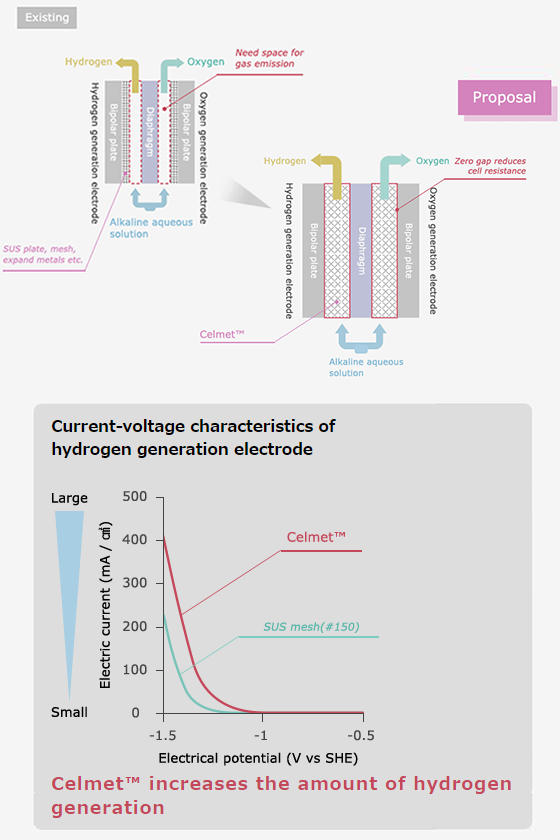

5」Electrodes of Alkali Water Electrolysis

Celmet™ has been considered as industrial hydrogen generator.

- Advantages of applying Celmet™

-

Voltage reduction of alkaline water electrode cell

Celmet™ is metal foam so that a zero-gap structure is possible and can reduce resistance of solution.

-

Improvement of hydrogen generation efficiency

Compared to lath or mesh, applying Celmet™ to hydrogen electrode can increase the amount of hydrogen without increasing the cell voltage due to its large surface area.

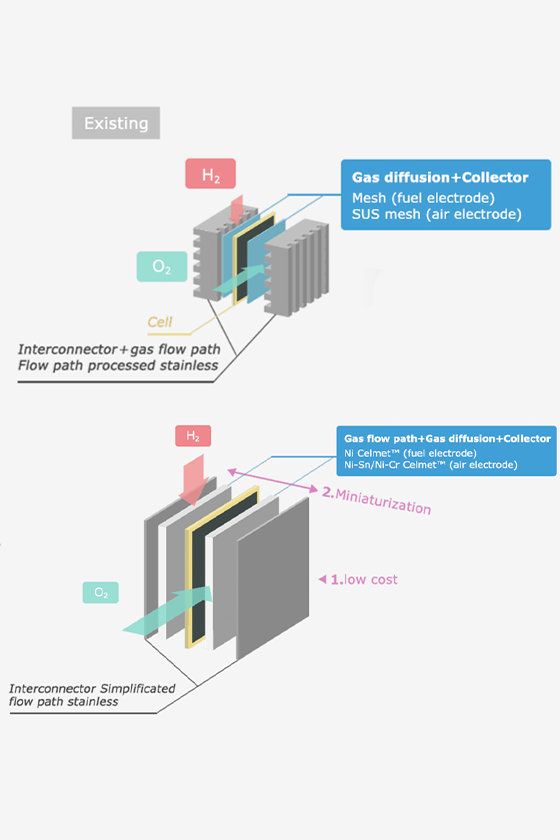

6」Fuel Cells (SOFC)

Celmet™ has been adopted as current collector and gas flow path of industrial and institutional fuel cells.

-

No need for complex gas flow.

-

Celmet™ can make interconnector thinner so that Celmet™ functions as gas flow path and gas diffusion.

-

High porosity can reduce pressure loss.

-

Celmet™ can improve the fuel availability because fuel gas flows uniformly.

-

Ni alloy Celmet™ can be applied as air electrode, because it has good oxidation resistance.

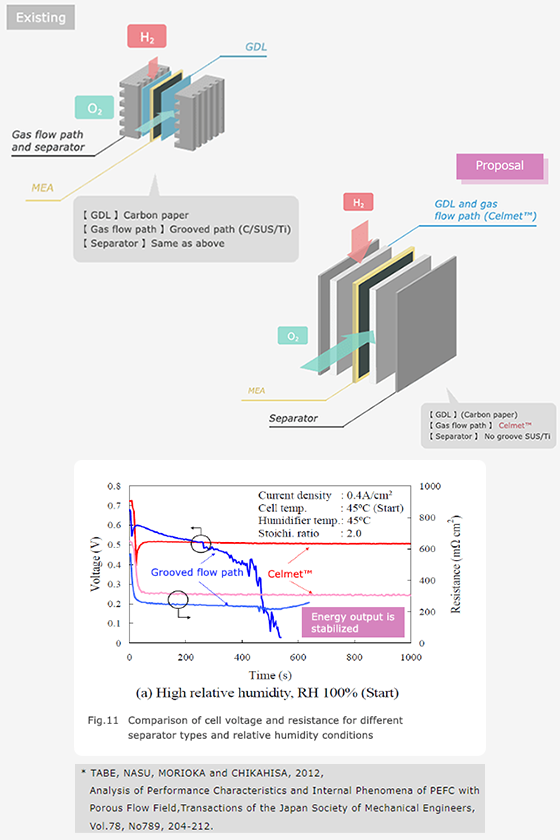

7」Fuel Cells (PEFC)

Celmet™ has been adopted as current collector and gas flow path of fuel cells for lift trucks

-

No need for GDL and separators with complex gas flow path, and lower pressure loss.

-

Celmet™ functions as gas flow path, gas diffusion and current collector.

-

Lower resistance and high-strength compared to carbon paper.

-

Higher current collection performance and improved flooding resistance – drainage is improved by capillary of Celmet™.