Product Information

Grade and Thickness

| Grade | Number of Cell [representative per inch] |

Number of Cell [tolerance per inch] |

Cell Size [mm] |

Pore Size [mm] |

Specific Surface Area [m²/m³] |

■Standard Thickness[mm] | |||||||

| 1.2 | 1.4 | 1.6 | 2.0 | 3.0 | 5.0 | 7.0 | 10.0 | ||||||

| #1 | 8 | 5~11 | 3.18 | 1.59 | 250 | ||||||||

| #2 | 13 | 11~16 | 1.95 | 0.98 | 500 | ||||||||

| #3 | 20 | 16~24 | 1.27 | 0.64 | 850 | ||||||||

| #4 | 30 | 26~34 | 0.85 | 0.43 | 1,250 | ||||||||

| #5 | 40 | 36~44 | 0.64 | 0.32 | 1,850 | ||||||||

| #6 | 47 | 40~53 | 0.54 | 0.27 | 2,800 | ||||||||

| #7 | 50 | 45~50 | 0.51 | 0.26 | 3,750 | ||||||||

| #8 | 55 | 53~58 | 0.45 | 0.23 | 5,800 | ||||||||

※This table shows specifications only for Ni, Ni-Cr, Ni-Sn Celmet™. Please contact us for other materials.

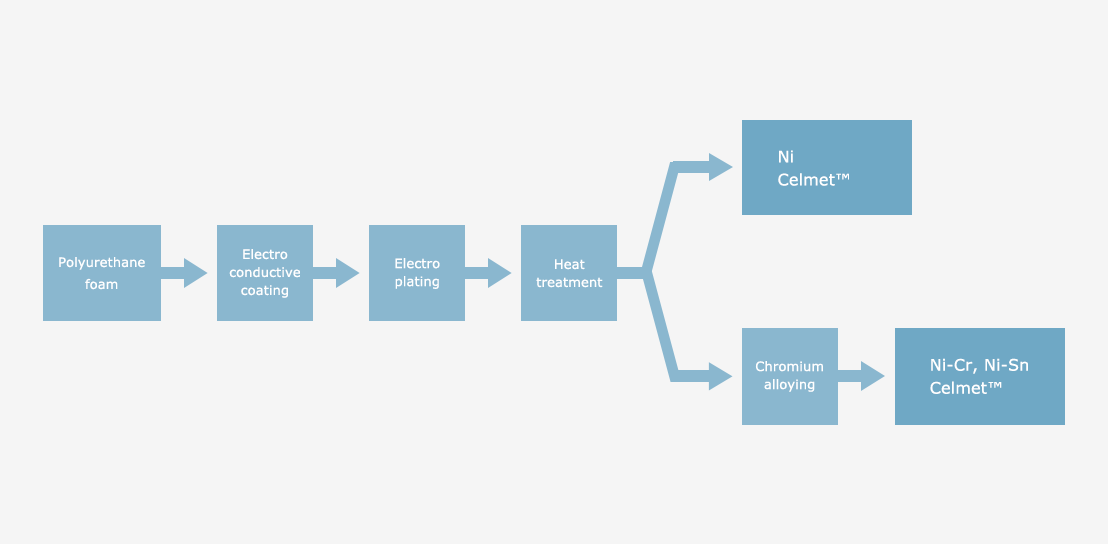

Production Process

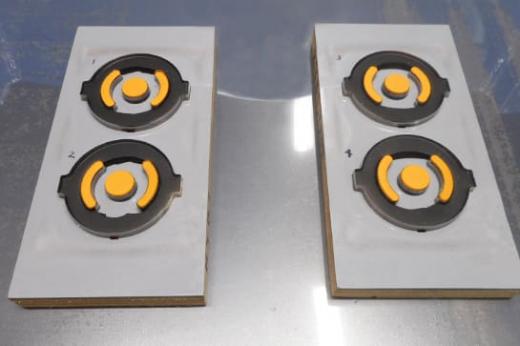

Machining Method

1」Blanking by blade die

-

For serial production

-

Low-cost and short lead time

2」Cutting by laser

-

Cut vertically without hanging

-

Circle, ring or other complicated shapes

3」Cutting by saw or shearing

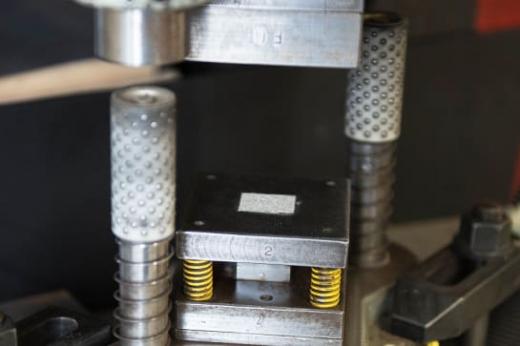

4」Thickness control by precision rolling

5」Blanking with die