Great Challenges Toward Improving Automotive Value and Creating New Value

CASE-Related Products Using the Group’s Integrated Power

Development organization that focuses on a project

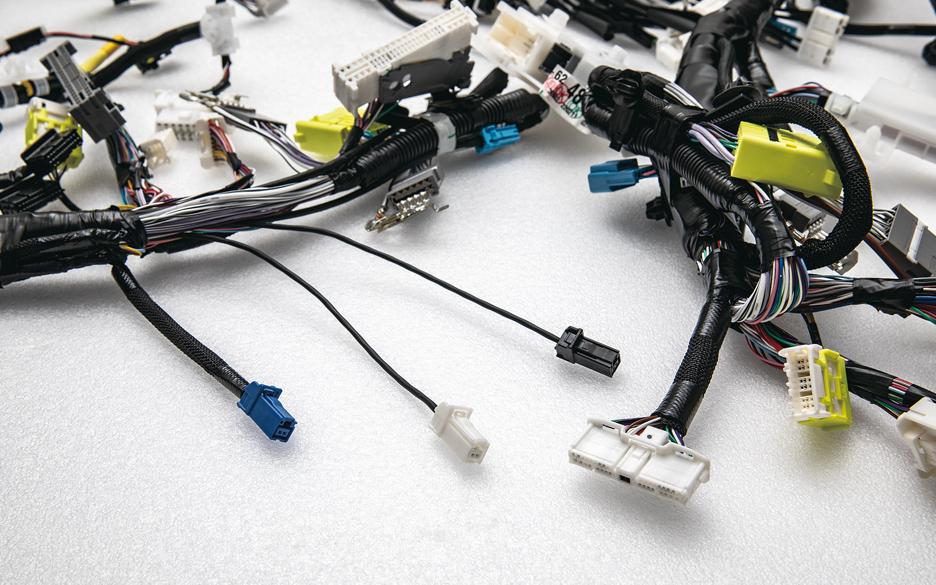

The principles of the CAS-EV Development Promotion Division (CASEV) for CASE are to integrate the Environment and Energy business and the Infocommunications business with the Automotive business, and to create new products and technologies for connecting cars with energy and communications infrastructure. They will expand their business in the Electrification and Energy area and the Connected and Info-communications area, the strengths of the Sumitomo Electric Group. Specifically, they will produce future wiring harness-related products on the basis of the core business of the wiring harness. This is because they have a project-based organization structure. CAS-EV has several sections, but does not use a vertically divided structure to work on CASE. They first examine areas of CASE from the upstream layer, such as infrastructure, then classify issues into architecture, Autonomous (driving), Electric (electrification), MaaS,* Connected, and other CASE-related areas, and finally start development in specific projects. Major on-going projects include high-speed communications, vehicle structure, battery-related, architecture, and infrastructure projects. The following are the results and products produced by these projects.

* Maas is an abbreviation for Mobility as a Service, and means the next-generation transportation service that incorporates existing transportation modes and services with various technological solutions, such as automated driving and AI.

Achieving high-speed and largecapacity communications essential to autonomous driving

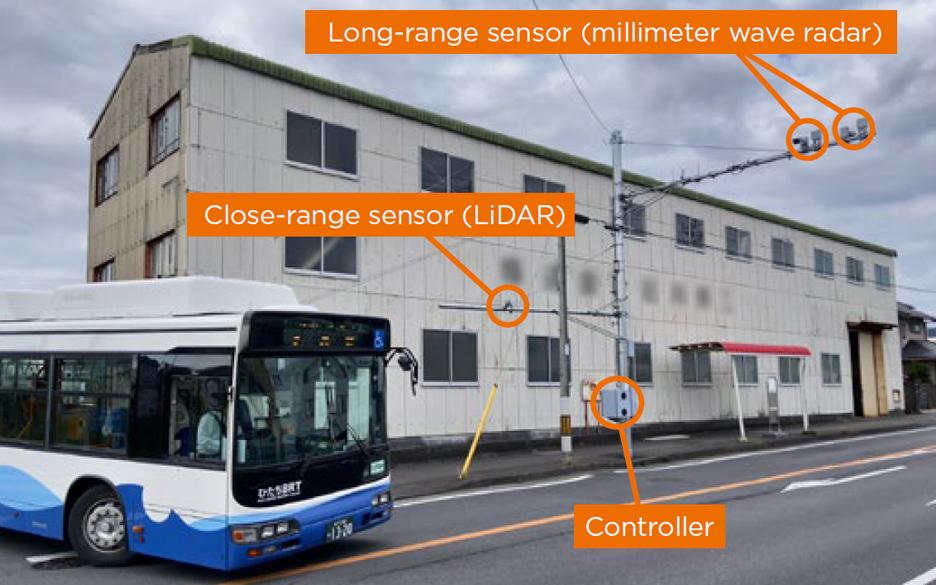

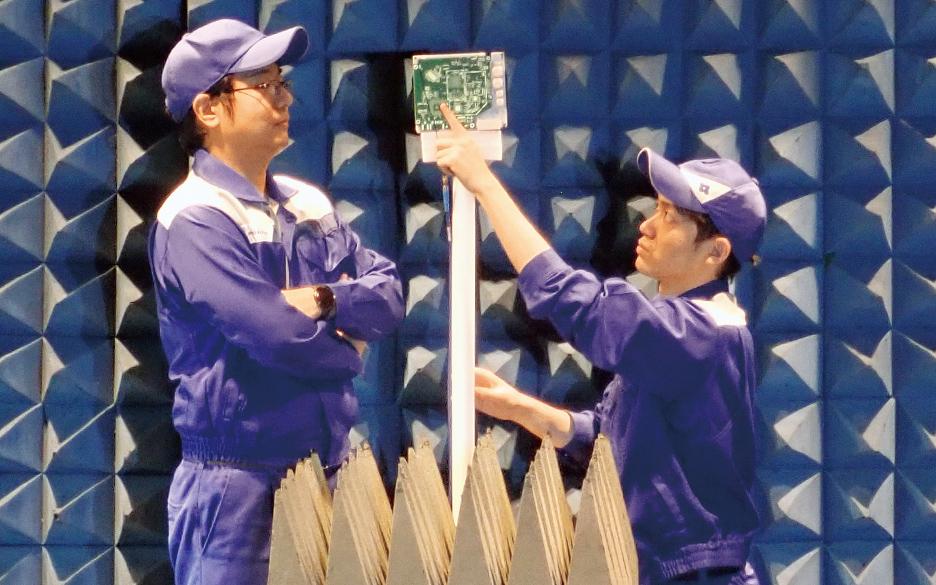

“Connected” in CASE refers to “connected cars.” Various kinds of data, including the vehicle conditions and road conditions around the vehicle, are obtained from sensors, and are accumulated and analyzed through networks. When advancement of “Connected” is achieved and safety is secured, “Autonomous” or fully autonomous driving will be realized. CAS-EV has been committed to highspeed and large-capacity communications to realize autonomous driving with connected cars. They have verified all the requirements for high-current and high-speed communications connectors and high-speed communications harness to realize “Connected,” which enables autonomous driving level 3. Autonomous driving level 3 is a driving mode where the system is in charge of all driving operations under certain conditions and the driver intervenes in an emergency. (Level 5 is fully autonomous driving.) A high-speed wiring harness/100 M ethernet, a wiring harness compatible with level 3, is supplied to automakers for implementation. In addition, they joined a demonstration project introducing autonomous driving buses in Hitachi City, Ibaraki Prefecture, as part of efforts to achieve “connected cars” communicating with the outside. They installed road-side sensors and vehicleto- road communication devices cooperating with vehicles to explore issues relating to autonomous driving buses running on specified roads. In the future, many cameras and detection sensors of other surrounding objects will be installed on vehicles, in-vehicle communication speed will be further enhanced, and eventually conventional electronic communications must be replaced with optical communications and an optical harness. Through high-speed, large-capacity communications, they aim to realize connected cars communicating with devices inside and outside the vehicle.

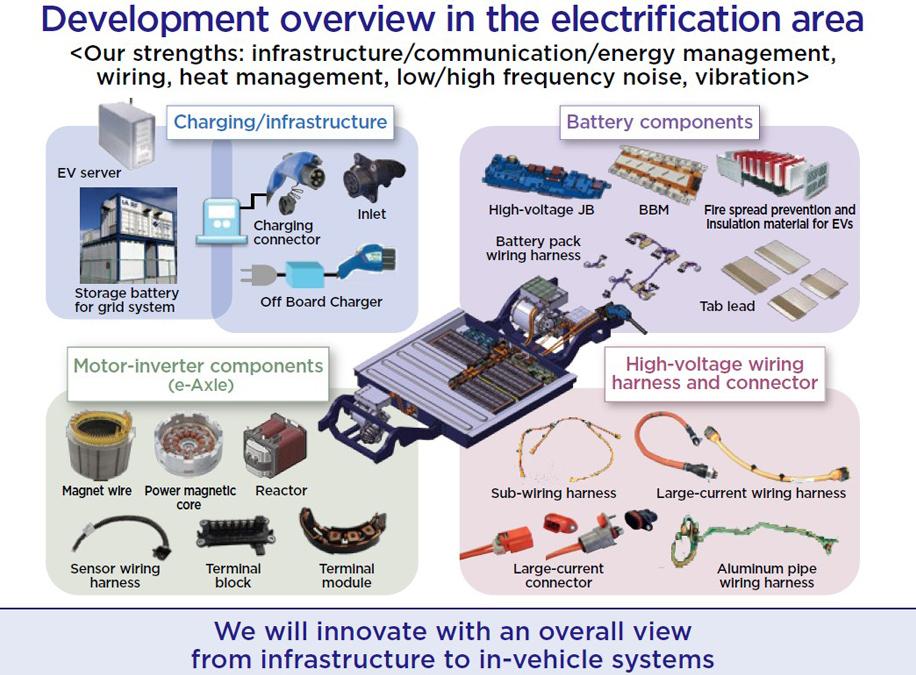

End-to-end electrification from infrastructure to batteries/motors

Electric (electrification), an aspect of CASE, is an area where the Sumitomo Electric Group has competence, and CAS-EV has been developing many parts in the area. First, it addressed the increase in capacity of batteries installed in EVs. A high-voltage battery pack integrates a battery with an electronic control unit (ECU) that regulates a high voltage of approximately 400 V, a sensor that measures the voltage, and a wiring harness that connects them to achieve weight reduction, high durability, safety, and cost efficiency in EVs. The ultimate aim is to produce housing-free, vehicle-integrated battery packs. Another result of CASEV is a high-voltage junction box, which connects more complicated electric circuits of a battery pack.

Electric power is controlled by an inverter to drive a motor, which rotates tires through the use of gears. The powertrain is integrated into an e-Axle, which has great advantages of reduced size, weight, and cost. Rectangular magnet wire improves motor driving efficiency, a powder magnetic core contributes to downsizing, and a bus ring simplifies wiring operations. Around an inverter, a reactor maintains a constant current, and a terminal block eliminates the effects of generated noise on circuits. CAS-EV have been developing harnesses for sensors, terminal modules, and other various parts and devices essential to an e-Axle.

Other efforts are focused on building charging infrastructure and developing product technologies specific to EVs, including high-power charging connectors and inlets to reduce charging time, energy management systems to efficiently supply electricity to power grids and households, and battery reuse to pursue sustainability. Thus, CAS-EV have actively promoted the development and sales of products for electrification.

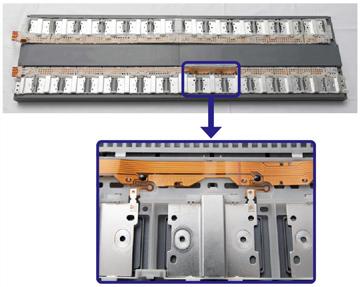

Battery bus bar module (BBM)

Batteries incorporated into EVs comprise a group of laminated and connected single-unit batteries called “cells,” which are sufficiently powerful to generate power for driving. The bus bar module is used to connect the electrodes of the cells and the voltage detection circuit. This is an essential part allowing the flow of a large current, and affects charging and discharging efficiency. CAS-EV has contributed to low-resistant connection between the electrodes and the bus bar, and a space-saving design.

Since more cells are used to increase the capacity over a longer range, parts in a pack are required to save more space. To solve the issue, FPCs (flexible printed circuits) are adopted. FPCs, which allow wiring to be denser and thinner than electric wire, contribute to reducing the thickness of battery packs.

High-voltage connector

Waterproof and electromagnetically shielded connectors suitable for high-voltage wiring used in EVs, HEVs, and FCVs. They are used for electrical connections between inverters, motors, and batteries.

High-voltage junction box (JB)

Equipped with circuit protection devices, such as relays and fuses, JBs centrally connect electric circuits in battery packs. With a function that trips circuit breakers when an abnormality is detected, JBs play an important role in securing high-voltage safety. In addition, a technique to dissipate heat from complicated circuits is required.

Driving the times with the integrated capabilities of the Group

It has been about two-and-a-half years since CAS-EV officially started as a division. General Manager Hirai described their efforts thus far.

“We have sincerely made efforts to become a development partner of automakers. The results are highly evaluated by automakers. However, I really feel that we have not gone far enough with our attitude and mindset toward the job, not as a supplier but as a partner. I believe that members have steadily grown since CASE-EV started, but we must reach a higher level of awareness and thinking. We must always have a car-centric perspective and awareness that our job is to improve the value of cars. We will continue efforts to receive a high evaluation from automakers as a partner,” said Hirai.

What is needed to accelerate the efforts of CAS-EV and to establish a solid presence of the Sumitomo Electric Group?

“The primary issue of CAS-EV members is to grow into a higher-level partner different from other companies by accumulating experience and gaining knowledge and skills. The next issue is to exploit various seeds in the Group, and to optimally transform them into a powerful driving force. Efforts on CASE cannot be pursued only by the Automotive Business Unit. I think it is important to collaborate with other Business Units or to involve affiliate companies. When we use the Sumitomo Electric Group’s integrated power, I am sure that we can work with automakers in the CASE era and become a driving force,” said Hirai.

The advent of CASE has impacted every aspect and is introducing drastic changes in the auto industry. As cars and society enter a new era, the great challenges the Sumitomo Electric Group has taken on should yield encouraging results in the future.

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.