Meeting the Needs of the Automotive Revolution

Transformation from a Supplier to a Partner

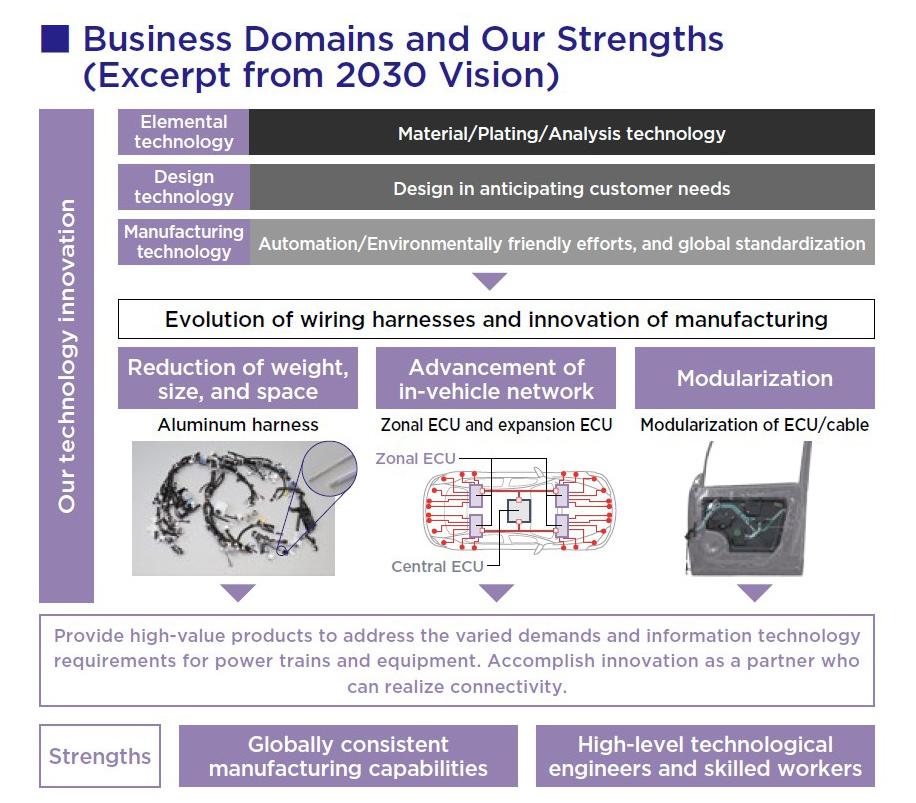

Wiring harness, the core business of mobility

The Sumitomo Electric Group has set the wiring harness as a core business in the mobility area. The wiring harness is a collective component that bundles multiple electrical wires for in-vehicle power supply and signal transmission purposes. It is akin to the blood vessels or the nervous system in a human body, and serves as the lifeline of an automobile. The wiring harness business has shown aggressive development since 2000. How will Mitsuo Nishida—who has engaged in the automotive business, including that of the wiring harness, for about 40 years—face this new era where CASE is promoted around the world?

“We have established three principles of action for the wiring harness business: Professionalism, Teamwork, and Challenge. Among these, I believe that Professionalism is particularly important and that PROin Professionalism stands for the three factors of Profit, Reliability, and Originality. Profit doesn’t mean what is good will sell, but rather, what sells is good. Originality means ‘Be a craftsperson.’ I think Reliability is most important, and have strived to ensure this. The Analects of Confucius say ‘Without trust, we cannot obtain a foothold.’ I think that the same applies in business. I have focused on establishing Reliability, such as trust relationships with stakeholders, manufacturing without cutting corners, and unrivaled technology in the wiring harness field. This will not change in the CASE era,” said Nishida.

Connecting partners will expand the Connected business

We set a vision for the wiring harness business in 2000. At first, the vision was to achieve the world’s top market share. But after achieving the top share, we aimed to become a megasupplier, setting the wiring harness as the core of our business.

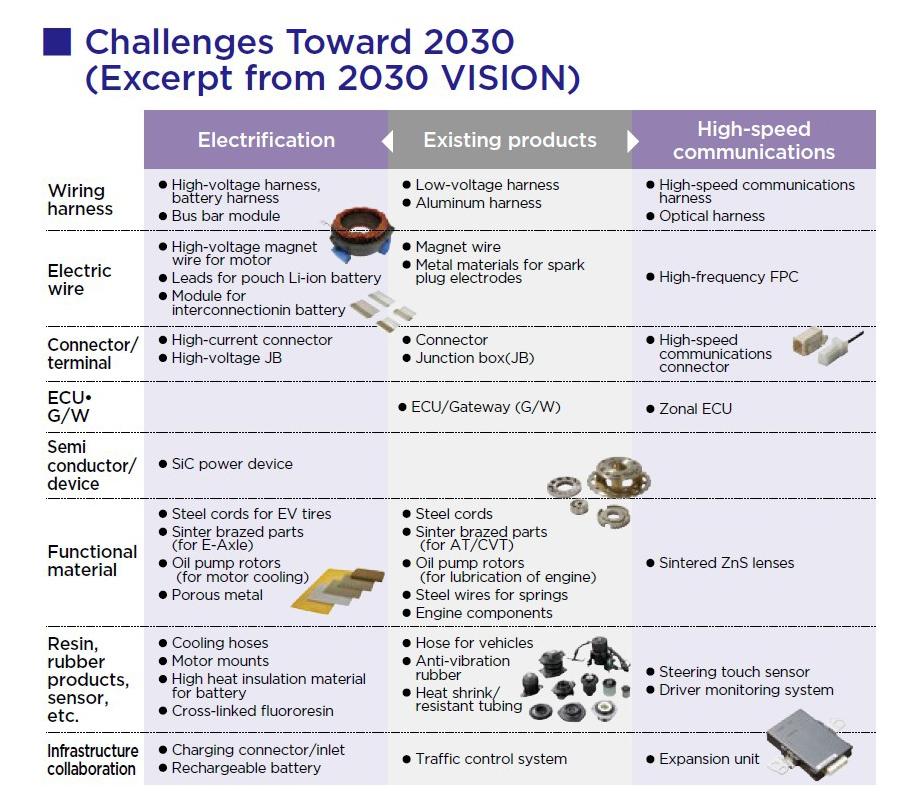

“We have been a supplier thus far. We have supplied our products as a Tier 1 automotive supplier (prime contractor). We have manufactured products as an auto parts maker, emphasizing costs, quality, and delivery. However, we are facing a drastic paradigm shift in the CASE era. To put it simply, automakers request that we consider how cars will change from now on from the viewpoint of an auto parts maker. To help shape a better future of the automobile society, they seek our cooperation and collaboration with them. Under these circumstances, we have set the aim of expanding the Connected business as a Connecting partner in mobility as a new vision in the wiring harness business. Transitioning from a supplier into a partner is a major change that CASE has brought about,” said Nishida.

To transition from a supplier into a partner, we must change our mindset. Furthermore, we must obtain a bird’seye viewpoint, new knowledge, and skills to see the big picture of cars. The mobility business of the Sumitomo Electric Group has entered a new phase.

Started the CAS-EV Development Promotion Div. to become a partner

“Technology proposal capabilities are essential to becoming a partner of automakers. First, we started the predecessor organization, the CAS-EV Development Promotion Office, to improve and cultivate such capabilities. I requested staff members to thoroughly discuss how cars will change and what auto parts will be required. Since this is a for-profit business, we have to obtain a high evaluation of our proposal from automakers. Recently, the CAS-EV Development Promotion Division has gradually been producing favorable results, and I want to accelerate these activities. In addition, since we have many auto-related sections in our company, we will integrate them and launch new businesses under the initiative of the Automotive Business Unit,” said Nishida.

While focusing on CASE, Nishida points out that turning steady profits from existing products is important. The wiring harness, which is the lifeline of a car, will not be abandoned unless the structure of the automobile drastically changes.

“Although the CASE trends are developing, high demand for existing products will continue at least until 2030. In detail, we expect that sales of existing products will account for about 80% of sales in the mobility business in 2030, and CASE-related products for 20%. We have determined to develop CASE-related products while earning steady profits from existing products as a group of professionals in the wiring harness field. Therefore, strengthening the wiring harness business is also a major challenge from the viewpoint of the whole mobility business. Recently, our group has been seriously damaged by the COVID-19 pandemic, the global semiconductor shortage, and the Russian invasion of Ukraine. We must attain flexibility and strength to address such various risks,” said Nishida.

Nishida has a strong attachment to the wiring harness. Currently, the wiring harness is produced in about 30 countries worldwide, and 2% of the total is produced at eight plants in Japan. Technical innovation, such as automation, is promoted at those plants.

“The plants in Japan have a mother function. As wiring harness manufacturing hubs, they support technical development and provide skill training and instruction. Manufacturing operations based on strong worksites are an aspect of Japanese culture we can rightly be proud of. Passing on Japanese manufacturing know-how is one of our missions,” said Nishida.

NEXT

Mobility × Energy × Communication = Connected Society

– Impact of CASE and the Goal of CAS-EV –

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.