Path to Commercialization of the Irradiation and Cross-Linking Process

A technology that has underpinned the basic industries in Japan

Development of an electron beam processing system;

accelerate electrons by applying a high voltage

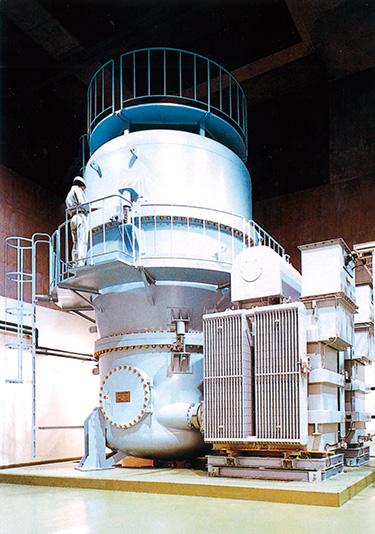

Soon after the discovery of cross-linking phenomenon in the 1950s, the Japanese government launched studies on industrial applications of radiation (mainly electron beams and gamma rays). The Sumitomo Electric Group started research on the irradiation and cross-linking process by inviting career bureaucrats in the engineering field from the Ministry of International Trade and Industry (currently the Ministry of Economy, Trade and Industry). The objective was to develop new materials and products with unique characteristics such as heat resistance, abrasion resistance, oil resistance and chemical resistance by irradiating electron beams on polymer materials to create cross-linking. Two new organizations were established in the research group. One was the Applied Physics Laboratory to develop an electron beam processing system, and the other was the Product Development Section to study potential products derived from the application of the irradiation and cross-linking process. During the study to develop a system, the staff members of the Applied Physics Laboratory contacted Nissin Electric, a capacitor manufacturer whose engineering capability was highly evaluated, to consider the possibility of joint development. In 1957, the two companies embarked on the development of a system. An electron beam processing system (EPS) is designed to take out electrons accelerated in a high vacuum by a high voltage into the atmosphere. The accelerated electrons are irradiated on polymer materials to trigger a chemical reaction called cross-link bonding. The irradiation and cross-linking process is characterized by high-speed cross-linking (in seconds) compared to other cross-linking techniques that use heat and chemicals. Other advantages include fewer restrictions on the materials subject to cross-linking and low environmental impact.

Development of high-value-added products by utilizing

the proprietary material blending technology

The irradiation and cross-linking process is achieved by composite technologies such as high voltage technology, beam engineering technology and high vacuum technology. Sumitomo Electric overcame those technical challenges and set up the first electron beam accelerator for commercial production at its plant in Osaka (Kumatori) in 1964. Basic research and product development were promoted to reform and improve various polymer materials by irradiating electron beams and creating cross-linking bonds. However, there was a concern from the beginning of the development. The equipment cost of the electron beam accelerator was high. It was imperative to improve productivity in an economically efficient manner and develop products.

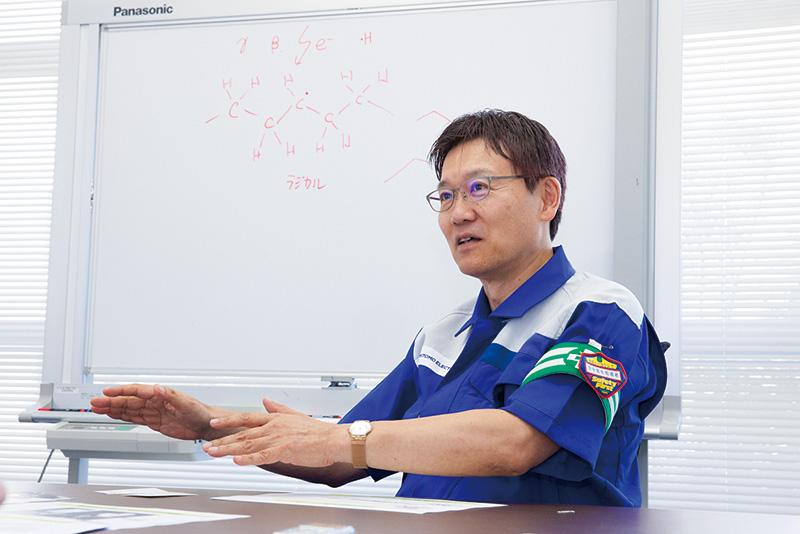

“For the most part, the irradiation and cross-linking business was initiated by ‘the seeds of the ideas’ instead of ‘needs’. However, efforts were made to identify needs that could utilize the cross-linking. Against this backdrop, we have been working to date to develop high-value-added products that leverage our proprietary material composite technology. This technology is one of the major factors that have achieved the widespread use of our irradiated and cross-linked products and ensured differentiation from competitors,” said Hiroshi Hayami, General Manager of the Energy and Electronics Materials Laboratory.

Subsequently, the two companies took different courses. The Sumitomo Electric Group focused on product development by applying the irradiation and cross-linking process, while Nissin Electric focused on improvement of the system. The Sumitomo Electric Group registered the IRRAX® trademark for irradiated and cross-linked products, and commercialized IRRAX® electric wires, IRRAX® tubes, IRRAX® tapes and SUMITUBE® heat-shrinkable tubing by using the electron beam accelerator for research. Meanwhile, irradiated and cross-linked polyethylene was applied to package bags for udon noodles. Sumitomo Electric promoted development of pioneering products for food packaging. Based on the positive feedback from the market, Sumitomo Electric set up a new system in Kumatori and started full-scale industrial production.

Supplying irradiated and cross-linked products to the electronics industry and auto industry

Japan was in its high economic growth period. The economic growth was led by the electronics industry (for home appliances and information equipment, etc.) and the automotive industry. This served as a springboard for the development of the irradiation and cross-linking business of the Sumitomo Electric Group. High heat resistance was required for electric wires used for interconnect wiring of electronic equipment including electric home appliances such as TV sets and air conditioners. The irradiated and cross-linked electric wires played an important role. Electric wires and cables were required to meet the flame retardancy, heat resistance and electrical insulation requirements from the viewpoint of safety. The Sumitomo Electric Group was highly evaluated for supplying cross-linking electric wires that met market needs. Regarding automobiles, high heat resistance and oil resistance were required in the engine bay and for sensors due to the enhanced functionality. Wiring harnesses are assemblies of electric wires that are arranged throughout an automobile. About 10% of the electric wires used for wiring harnesses are cross-linked polyvinyl chloride (PVC) and cross-linked flame-retardant polyethylene electric wires. PVC can be cross-linked only by the irradiation and cross-linking process. The cross-linked PVC electric wires came into widespread use as heat-resistant electric wires for automotive wiring harnesses. Antilock brake system (ABS) sensor cables are noteworthy in the automotive field. These cables transmit electric signals from the sensors that detect the rotational speed of the wheels to the engine control unit. They are used for wiring in the severe environment adjacent to the wheel wells. The sheath is made from polyurethane resins with improved reliability derived from the process. The commercial application of ABS, which increased the safety performance of automobiles, was underpinned by the Sumitomo Electric Group’s cross-linking electric wires. As for the heat-shrinkable tubing, it has been used for various applications such as insulation process of the electric wire terminals, electric field relaxation of power cable terminals, environmental seal for connections and branches of wiring harnesses and corrosion protection for automobiles. Since its early days, the irradiation and cross-linking process has helped Sumitomo Electric offer products in a timely manner to meet the needs of the changing times, and has underpinned the development of the electronics and auto industries that are Japan’s key industries.

Meanwhile, Nissin Electric was improving the electron beam processing system in various aspects.

“The electron beam processing system has advanced to meet the needs of customers. We worked to increase the output. In 1989, we developed the world’s largest electron beam accelerator of 5 MV. We have since been making continuous efforts to refine auxiliary equipment to improve productivity, reduce the size of the overall system, minimize the need for maintenance and extend the service life. The collaboration between our system and the product development capability of the Sumitomo Electric Group has played a key role in developing the market. We hope to maintain this close relationship to launch into new fields of application toward the next generation,” says Yasuhisa Hoshi, Standing Advisor, Nissin Electric.

NEXT

Identifying and meeting the needs of the changing times to develop products

—Current status of the irradiation and cross-linking process and sales network

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.