Titanium

We provide titanium alloy parts with excellent tensile strength, Young's modulus, and wear resistance.

Although pure titanium and titanium alloys are widely used as general-purpose lightweight structural materials, their applications have been limited due to their inferior characteristics of wear resistance, tensile strength, and Young's modulus.

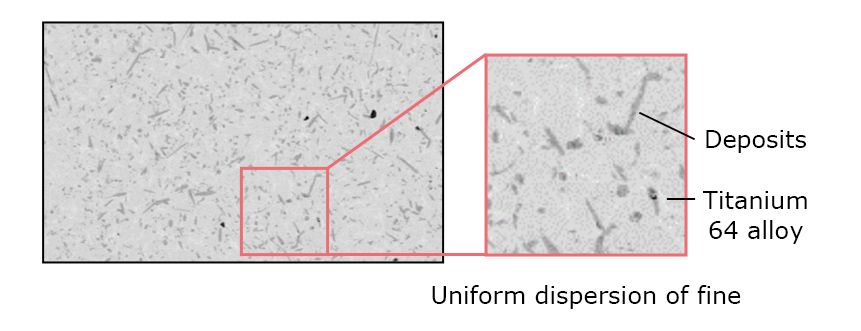

Accordingly, we have developed a titanium alloy in which fine ceramic particles are uniformly dispersed using titanium 64 alloy as a base material. Its strength, rigidity and hardness (wear resistance) are superior to those of conventional titanium 64 alloys. This development has enabled the use of pure titanium and titanium alloys in harsh environments where it had previously been difficult to apply them.

Proposed applications : Semiconductor manufacturing equipment, industrial pumps

Material structure

Material characteristics

| Material | Titanium64 alloy | Developed material※2 | ||

| Young's modulus | GPa | 110 | 140 | |

| Tensile strength | Room temperature | MPa | 980 | 1100 |

| 400℃ | MPa | 680 | 710 | |

| Abrasion depth※1 | ㎛ | 1050 | 220 | |

| Hardness | HRC | 30 | 37 | |

※1 Amount of wear in a test using a pin-on-disk grinding test machine under the same conditions.

※2 Material characteristics shown above are an example. It is possible to adjust the material characteristics by changing the base titanium alloy composition and deposits content.

Titanium alloy powdered metal parts

Use case #1: High-Speed Rotation x High-Precision Parts

Applications

Motor parts, reducer parts, rotating tool holders

Advantages

High dimensional accuracy of parts is maintained in the actual usage environment since their deformation due to centrifugal force is suppressed.

Use case #2: Corrosive Environment x Sliding Parts

Applications

Bearings, rotating parts of chemical pumps (impellers, rotors, etc.)

Advantages

The corrosion resistance and wear resistance of parts are achieved at a high level.

Use case #3: Lightweight x High-Strength Parts

Applications

Bicycle sprockets and drone parts

Advantages

Its strength is higher than that of titanium 64, which can enable products to be thinner and smaller than conventional titanium alloy products.