19 November 2024

Sumitomo Electric Signs a Contract with DPS Inc. for International Resource Circulation through Recovery of Rare Metal from Wastewater during Flexible Printed Circuit Manufacturing

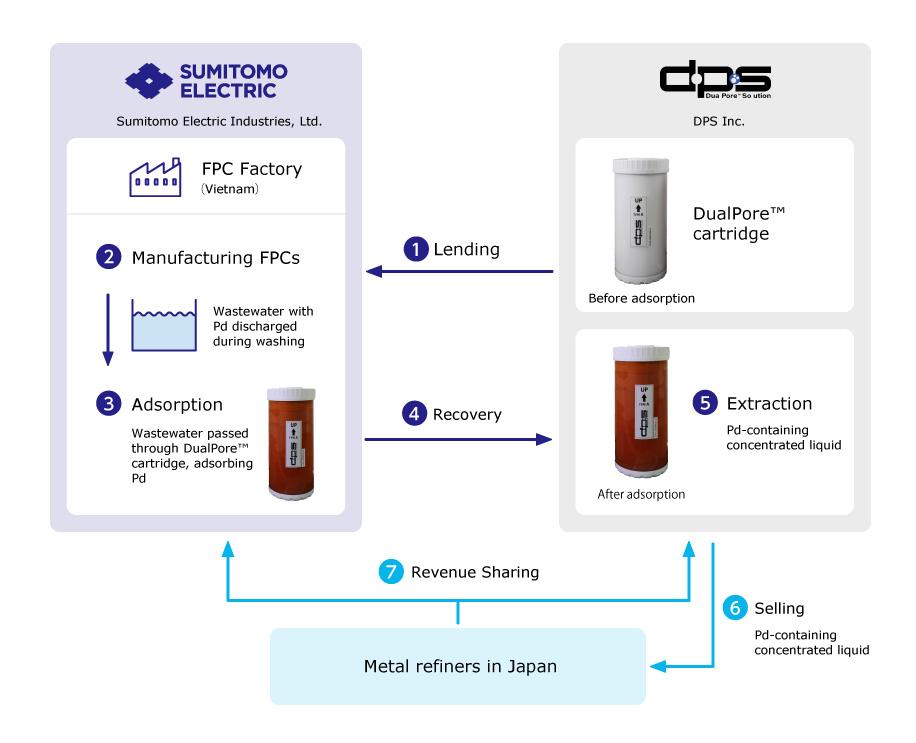

Sumitomo Electric Industries, Ltd. concluded an agreement with DPS Inc. on November 8 for the recovery of rare metals used in the manufacturing process of flexible printed circuits (FPCs).

In the manufacturing process of FPCs, various plating processes are performed, such as copper plating to make conductive circuits formed in layers and gold plating to surface-treat the external connections. Palladium (Pd), a rare metal, is often used as a catalyst to efficiently perform these plating processes. When the chemical solution containing Pd adhering to the FPC surface is washed away in the washing process, a small amount of Pd has conventionally been treated as wastewater without recovery.

Through the "Asia Business Creation Platform*1," DPS recently proposed a technology to our FPC manufacturing base in Vietnam*2 for adsorbing and recovering Pd contained in wastewater at ultra-low concentrations with the application of its proprietary silica gel structure, DualPore™. Following successful verification, we decided to adopt the technology.

In addition, by establishing a scheme to sell the recovered Pd to metal refiners in Japan, we aim to reduce costs, promote the international resource circulation of Pd, and reduce the environmental impact associated with mining and refining.

We are currently considering applying DPS's technology to other FPC manufacturing bases and non-FPC manufacturing processes. We are committed to promoting initiatives to realize a sustainable society, including carbon neutrality and circular economy.

Comment from President Haku of DPS DPS's

DualPore™ technology has been officially adopted after field trials at Sumitomo Electric, which has the most advanced production technology including FPC manufacturing. This fact is a testament to the high evaluation of the technology's potential not only for Pd recovery but also for a wide range of applications in production technology. This project is a model case of using DualPore™ to concentrate and immobilize rare metals and other valuable resources from dilute liquids and transport them back to Japan as a means of international circulation. We hope that this initiative will further contribute to the development of our country, which has few mineral resources.

DPS Inc.

Established in 2017, DPS manufactures and sells products based on DualPore™particle technology.

https://www.dps-inc.co.jp/en/

*1Asia Business Creation Platform (ABC Platform)

An initiative to promote cooperation among companies and organizations in human resources, technology, services, etc. to create business and revitalize the economy in Asia and Japan. The initiative was launched in April 2019 through collaboration with the Kansai Economic Federation (Kankeiren) and economic organizations from the seven nations (Indonesia, Malaysia, Myanmar, Philippines, Singapore, Thailand, Vietnam) of the Association of Southeast Asian Nations (ASEAN).

https://www.abc-pf.org/en/

*2 SEI Electronic Components (Vietnam), Ltd.

[Reference]

DualPore™

A new adsorbent material with a special three-dimensional structure developed by DPS (patented). By applying surface processing technology to silica gel, a well-known desiccant, this environmentally friendly material can efficiently adsorb not only water but also various substances.

https://www.dps-inc.co.jp/en/t-dp/