Making Strides in Seawater Desalination and Rare Earth Recovery

PTFE Hollow Fiber Membrane Designed for Membrane Distillation

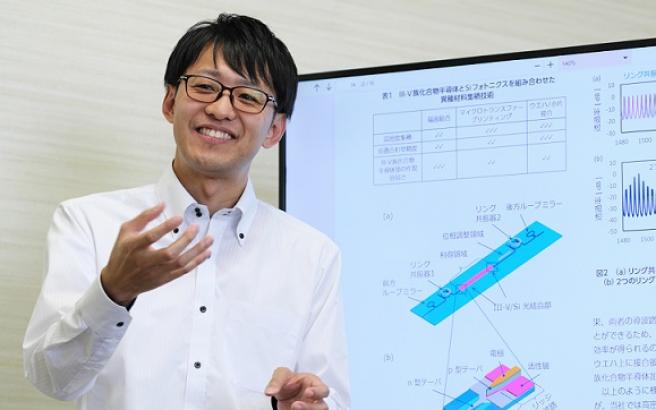

Hiroki Miyata

Assistant Manager, Energy and Electronics Materials Laboratory

The Earth, often described as a "water planet," faces a paradox where only 0.01% of its water resources are directly accessible for human use, primarily due to the vast majority being seawater or trapped in polar ice caps. Given the critical role this scarce resource plays in sustaining life and supporting various industries, addressing the growing water shortage is crucial.

The Sumitomo Electric Group has harnessed its globally recognized expertise in polytetrafluoroethylene (PTFE) porous technology to develop POREFLONTM hollow fiber membranes, now a cornerstone of advanced water treatment solutions. This innovative water treatment technology, which filters and purifies water, plays a key role in environmental conservation efforts throughout Asia and North America. Our latest research has furthered this commitment by successfully commercializing a next-generation PTFE membrane that desalinates seawater and recovers rare earth elements from water resources, thereby addressing water scarcity and environmental issues.

Focusing on membrane distillation for seawater desalination

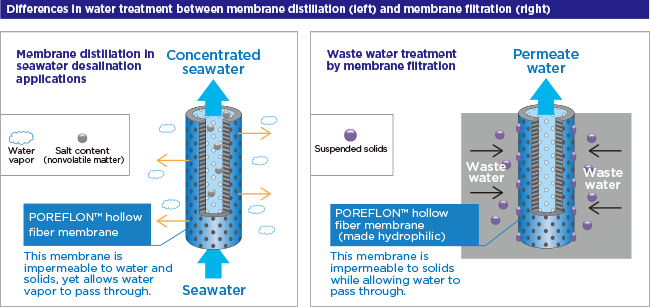

Sumitomo Electric Group's PTFE membranes* have led the market in the treatment of sewage and industrial wastewater. Traditionally, these membranes have filtered wastewater to remove solids. Nonetheless, the escalating demand for seawater desalination had driven us to engineer a method that can separate not only solids but also salts dissolved in seawater.

We focused on membrane distillation, which can produce fresh water with a high recovery rate. In this process, seawater is heated and only water vapor passes through the membrane to produce fresh water. However, despite extensive research, no membrane had been developed that met the requirements of this process. This led us to consider the deployment of PTFE membranes as a potentially suitable solution.

*PTFE (polytetrafluoroethylene tetrafluoride) membrane

PTFE is a plastic material used in various industrial applications due to its non-adhesiveness, low friction, chemical resistance, weather resistance, electrical properties, and heat resistance. It is highly hydrophobic and, as a hollow fiber membrane made from a single material, it is 8 to 10 times stronger than other materials. The Sumitomo Electric Industries Group takes advantage of these properties of PTFE and uses it as a filtration membrane for water treatment.

Developing the world's first PTFE membrane suitable for membrane distillation

The challenge was to achieve both high water pressure resistance and gas permeability. When large amounts of water vapor pass through, it exerts significant pressure on the membrane. Decreasing the size of the pores does make the membrane robust, but it simultaneously hinders water vapor permeability, thereby reducing the amount of fresh water produced and lessening efficiency.

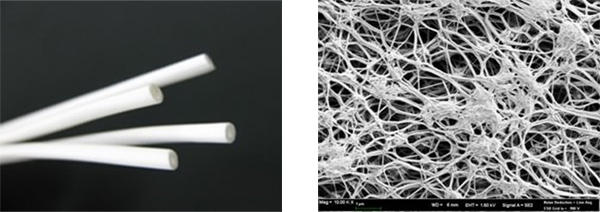

To address these issues, we initiated by transforming the conventional multilayer structure of the hollow fiber membrane into a single-layer and minimizing its pore size to fortify it against water pressure. Subsequently, we increased gas permeability by making the membrane thin and densely packing it in a module. These adjustments enhanced both the permeability of the membrane and the flow rate of the entire module. This, coupled with collaborative efforts with Sumitomo Electric Fine Polymer, Inc. in the rigorous evaluations of materials and prototypes, culminated in the development of a PTFE membrane module. This module achieves an average water flow rate of 17 L/h/m² and a remarkable 99% salt removal rate. These results mark a significant breakthrough and make this the world's first PTFE membrane module practical for membrane distillation, with potential applications in desalination, rare earth recovery, and salt pollution removal.

Microstructures of PTFE POREFLON™ hollow fiber membrane (left) and its surface (right)

Seeking solutions to global water shortages

Since I joined the Company, my goal of solving the world's water shortage has remained steadfast. Although we are a small R&D unit, our team has been tasked with a wide range of activities, from basic research to overseas production expansion, and I have been entrusted with a variety of responsibilities regardless of my age. The most rewarding part of this job is seeing the impact our products have on society. Currently, we are focusing on improving the production technology of PTFE membranes to make them available at a lower cost. Looking ahead, we intend to go beyond providing innovative water treatment systems and customer services to developing businesses that solve water treatment problems on a global scale by leveraging the comprehensive strengths of the Sumitomo Electric Group.

Related Information

[Press release] Sumitomo Electric commences joint development of membrane distillation technology with KMX Technologies

[Products] Water Treatment Membrane

[Project id] ‘“Water Planet” Increasingly Suffering Water Shortage’

[Project id] “Accelerating Membrane Distillation Technology Development to Expand Sumitomo Electric’s Water Treatment Business”

Sumitomo Electric Fine Polymer, Inc.

SUMITOMO ELECTRIC TECHNICAL REVIEW

A journal of technical papers explaining the Sumitomo Electric’s technologies. Technical papers are available in PDF format.

Learn more