Abrasion-resistant parts/materials

Products about Abrasion-resistant parts/materials

Teralink™ is a cross-linked thermoplastic polymer for optical components used in SMT applications. Mechanical grades for wear-resistant gears are also available.

Products Lineup

Teralink™S (sliding grade)

Teralink™ is a thermoplastic engineering plastic material that is cross-linked by irradiating electron beams onto molded components. Characterized by low abrasion loss, a low friction coefficient, and high fatigue strength, Teralink™S (sliding grade) ensures a longer service life than commercially available nylon and POM, and helps reduce the face width in design, thereby achieving reduction in space.

-

Teralink™S is characterized by low abrasion loss, a low friction coefficient, and high sliding performance.

-

Due to the high fatigue strength, this material achieves a longer service life than commercially available materials.

-

The face width can be reduced by 15%–40% compared with nylon 66.

-

Sliding parts including gears, washers, and sliders

FEX™ (cross-linked fluoroplastics)

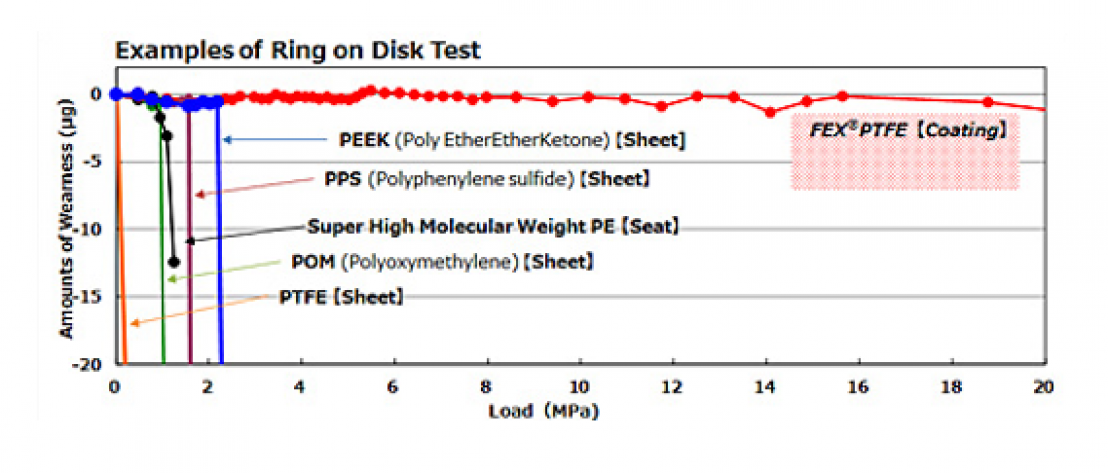

FEX™ (cross-linked fluoroplastics) is characterized by significant improvement in abrasion durability and adhesion with base materials, while retaining a low friction coefficient. The fluoroplastics are cross-linked by irradiating electron beams. Sumitomo Electric has been developing FEX™-coated products and other application products, which are expected to reduce torque and increase durability, heat resistance, wear resistance, weather resistance, mold releasability.

Discover more

For more details about the products or for any other inquiries please use the buttons below.