TERALINK™ Thermoplastic Molded Components

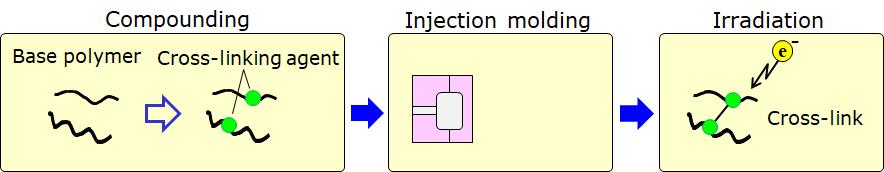

What is TERALINK™?

TERALINK™ are thermoplastic molded components cross-linked by irradiating electron-beam.

Advantages

-

High structural stability at temperatures above melting point

-

Higher strength at temperatures above Tg

-

Improved resistance to wear and fatigue

optical connectors

lens for LEDs

Products

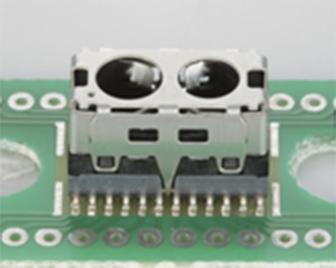

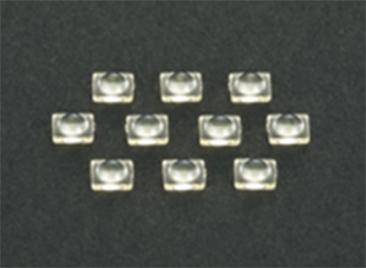

Optical components (TERALINK™ T)

- Lens for infrared SMD-type LEDs

- Lens package for optical connectors

-

High structural stability retained under reflow (260℃) process

suitable for SMT process

-

Transmittance* is over 90% in the range of 600nm~1100nm, and ~90% at 1300nm

*measured at RT with 2mmt plate

-

Injection molding applicable

cost effective compared to silicone or epoxy<br> high flexibility in designing of lens or/and supporting package

-

Hybrid structures of lens & holder realized in single molding process

no need for adhesives

gears , washers

Mechanical components (TERALINK™ S)

<Applications>

-

Gears and mechanical parts for industrial machines as well as commercial products

-

Low frictional sliding parts

-

Include high fatigue strength, low abrasion loss, and low friction coefficient

-

Longer service life than conventional nylon and POM

-

Components such as smaller (space-saving), more durable gears are available