A 50-Year History of Optical Fibers (Part 2)

A 50-Year History of Optical Fibers

Steadfast Commitment to Connecting the World through Fiber Optics

Part 2: An Ongoing Commitment to Pioneering the Future

Growth Period: 1990-2000

Belief in the Future of Optical Fiber

Complete Dedication to Technology

With the introduction of dense wavelength-division multiplexing (DWDM), the 1990s saw a period of dramatic progress in fiber optic communication technologies.

By applying DWDM around the zero chromatic dispersion wavelength, nonlinear optical impairments become non-negligible due to interactions of signals at different wavelengths, which degrades the signal quality. To reduce nonlinear impairments, a non-zero dispersion-shifted fiber (NZ-DSF) designed to purposefully avoid zero chromatic dispersion in the 1.55 µm band, followed by a dispersion compensating fiber (DCF) with negative chromatic dispersion to cancel the accumulated dispersion, were applied.

However, manufacturing NZ-DSF and DCF required the accurate formation of triple or quadruple concentric refractive index profiles. Forming such complex structures was not easy with the VAD method, and manufacturing saw constant struggles.

During this period, subscriber system technologies for bringing optical fiber to the home were also advanced. As application of SM fiber for subscriber systems in Japan was decided in 1988, Sumitomo Electric focused on the development of various cables and wiring products, in fierce competition with its competitors. The developed technologies culminated in the realization of Fiber To The Home (FTTH) networks that Japan pioneered in the 2000s.

Optical fibers began to spread in earnest worldwide from the late 1980s. To outperform the competition, Sumitomo Electric pursued plant construction for the mass production of optical fiber, aiming to establish an integrated production line that applied the latest technologies to all processes from preform fabrication to drawing and coloring. A mass production plant was completed and came into service at Yokohama Works in 1994, which was followed by a plant located in the Kiyohara Industrial Park in Tochigi Prefecture in 1999.

This period of advanced development witnessed the crystallization of Sumitomo Electric engineers’ power to continuously pursue and dedicate themselves entirely to technology.

Period of Radical Change: 2001-2011

Technologies of the Future

The Continuing Pursuit of Low-loss Optical Fiber

Investments in communications-related companies gained speed worldwide and peaked in 2000, with what became known as the dot-com bubble. However, the bubble, which was not supported by real demand, burst dramatically in 2001.

Nevertheless, demand for communications grew steadily with the full-fledged spread of the Internet and the emergence of new services such as image exchange via mobile phones. After bottoming out in 2004, optical fiber demand recovered to around 100 million km per year in 2006, the same level as during the dot-com bubble period, and since then demand for optical fiber has increased steadily. Sumitomo Electric, in the years that followed, overcame headwinds such as the Lehman Shock, the extremely strong yen, and the Great East Japan Earthquake by thoroughly reducing costs in line with its mission of "connecting the world through fiber optics.”

The revolutionary transmission technology following DWDM was digital coherent technology. Transmission capacity of 10 Tbps (= 100 wavelengths x 100 Gbps) per single optical fiber was also realized, and commercial use of digital coherent systems began from 2006.

With the adoption of digital coherent technologies, optical signal distortion caused by chromatic dispersion could be equalized at the receiver. As a result, requirements for suppressing chromatic dispersion in optical fibers became less strict, while demands for low loss and the suppression of nonlinear impairments increased. The nonlinear impairments could be suppressed by enlarging the core area of optical fiber to reduce the light power density. This was an advantageous development for the VAD method, which is capable of low loss and excels with relatively simple structures.

Relentless in its pursuit of low-loss optical fibers to deliver light farther, Sumitomo Electric continued to persevere and conduct developments that led to trends turning again in the direction of those areas in which Sumitomo Electric excelled.

Toward a New Society: 2012-

The Endless Battle for Ultra-low-loss

In the 2010s, growth in demand for communications accelerated even further, with global optical fiber demand reaching 500 million kilometers annually in 2018.

Since around 2013, when cloud services came into wide use on a global scale and cross-border data exchanges began to emerge, the number of transoceanic submarine fiber-optic cable projects continued to increase up to the present day. Accompanying this, Sumitomo Electric’s pure-silica core optical fibers (PSCFs) attracted much attention worldwide as ultra-low loss optical fibers for ultra-long distance transmission in submarine cables.

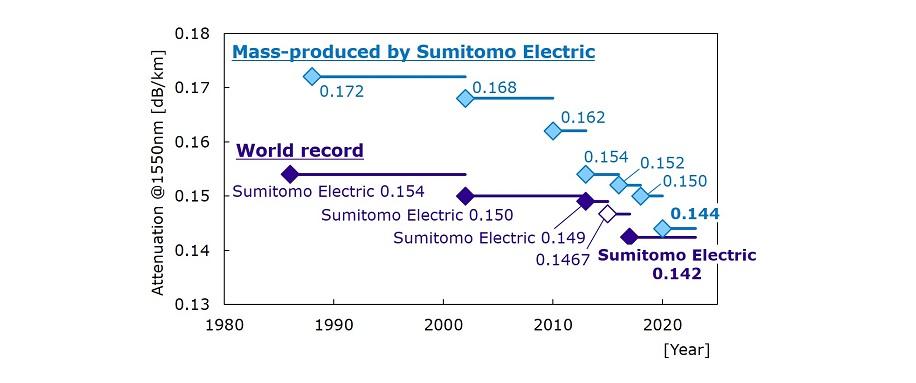

Sumitomo Electric developed PSCFs in the 1980s and has since set successive world records for low loss. The current best performance for transmission loss at 1.55 µm is 0.142 dB/km. Not only best performance, but also transmission loss for mass-produced products has been improved. Ultra-low-loss optical fiber products with a loss of 0.144 dB/km are now manufactured and commercially supplied.

Large-core-area ultra-low-loss optical fibers (such as Z-PLUS Fiber 150 ULL) with an effective core area of 110 to 150 µm2 for suppressing nonlinear impairments also have been commercialized and applied to submarine cables.

In recent years, major IT service providers have been actively constructing data centers for storing massive amounts of data.

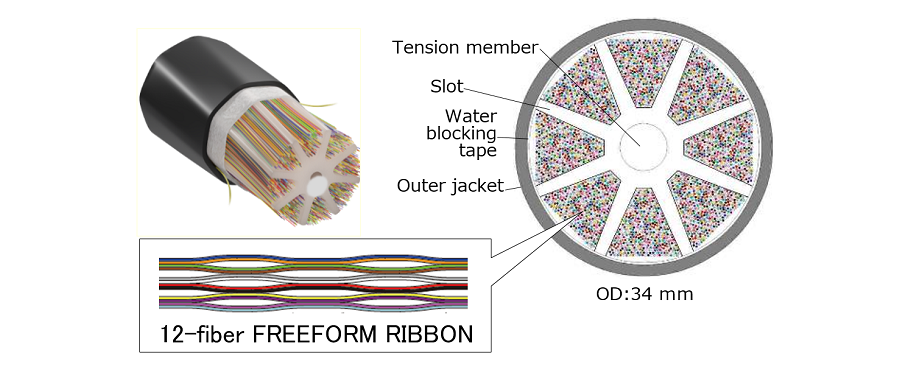

Large-scale data centers exhibit a strong need for installing large numbers of optical fibers in outdoor ducts, which requires the ability to densely pack optical fibers into a restricted space. Sumitomo Electric developed in response an ultra-high-density multi-fiber optical cable containing more than 3,456 fibers by using 12-fiber FREEFORM RIBBONs, and commercialized this for the first time in the world. FREEFORM RIBBONs consist of multiple optical fibers arranged in a ribbon-like configuration, with adjacent optical fibers intermittently bonded to each other. While enabling fusion splicing of these 12 fibers at once, the enhanced flexibility of the ribbon allows for dense arrangement in the space inside the cable, enabling ultra-high-density multi-fiber optical cables with 3,456 to 6,912 fibers.

Expansion of optical fiber transmission capacity has grown dramatically, and the transmission capacity in a conventional fiber is now approaching the theoretical limit of 100 Tbps. Multicore fiber (MCF), having multiple cores in a single fiber, is currently being proposed as the next-generation of optical fiber capable of breaking through this limit, and thereby, is attracting a great deal of attention. Sumitomo Electric has been leading cutting-edge research in areas such as proposals for MCFs that clarify and solve the phenomenon of crosstalk between multiple cores, along with developing MCFs in terms of their practical application.

Sumitomo Electric’s mission is to connect the world through optical fiber so as to deliver greater happiness to people around the globe. As such, its engineers will continue to challenge themselves in developing new technologies for fulfilling this mission. Therein lies the unwavering belief of Sumitomo Electric’s engineers.

Z-PLUS Fiber and FREEFORM RIBBON are trademarks or registered trademarks of Sumitomo Electric Industries, Ltd.