A 50-Year History of Optical Fibers (Part 1)

A 50-Year History of Optical Fibers

Steadfast Commitment to Connecting the World through Fiber Optics

Part 1: The Determined Pursuit of New Challenges

Founded in 1897, Sumitomo Electric Industries, Ltd. has over a 120-year history. Recognized as one of the world’s leading optical fiber manufacturers, the company has continuously challenged itself over the years to reduce transmission loss, setting new world records along the way.

Sumitomo Electric supplies the world with high-quality optical fibers and cables, including ultra-low-loss optical fibers, using the VAD method as its core technology – an optical fiber manufacturing method widely used throughout the industry today. To this day, the company continues to take on new challenges, while supporting the expansion of optical fiber communication networks, which serve as an indispensable lifeline to society.

We will now look at the evolutionary course optical fibers have taken over the past 50 years as well as the measures Sumitomo Electric has employed to contribute to the development of these fibers.

Early Days: 1964-1974

The Dawn of Optical Fiber’s History

Optical Fiber’s Technical History Begins Here

In 1966, Charles K. Kao of Standard Telecommunications Laboratories in the UK predicted the possibility of realizing transmission loss of below 20 dB/km with transition-metal-free high-purity glass fiber. Years later in 2009, Kao was awarded the Nobel Prize in Physics for this achievement. His prediction led to research on eliminating impurities in glass fibers, and in 1970, a silica glass optical fiber with a transmission loss of 20 dB/km was realized in the United States. From here on, optical fiber began its journey toward practical application.

This marked the dawn of optical fiber’s history for Sumitomo Electric as well. Important optical fiber technologies, such as pure-silica core fibers (PSCFs) and a concept of preform manufacturing techniques – which led to the Vapor-phase Axial Deposition (VAD) method that later became Sumitomo Electric’s core technology – were invented in the early 1970s.

Development Period: 1975-1984

Sumitomo Electric Begins Developing Optical Fibers in Earnest

Birth of the Foundation of Optical Fiber Technology

Japan’s Original VAD Method

In 1975, Nippon Telegraph and Telephone Public Corporation (now NTT), Sumitomo Electric, and two other cable manufacturers established a joint optical fiber research team.

Through their research, they developed the VAD method, an original Japanese preform manufacturing technique. Optical fiber is made by fabricating a preform consisting of a cylindrical block of glass, and then heating and melting it, to draw it out into thin threads. To promote the widespread adoption of optical fibers, a manufacturing method suitable for mass production was necessary as well as for ensuring low transmission loss. The key to the mass production of optical fibers was how best to manufacture a sufficiently large preform.

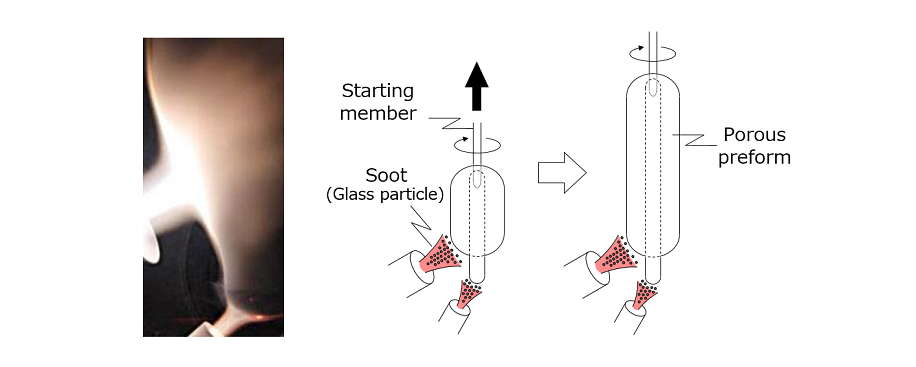

VAD is a method in which gaseous glass material is fed into an oxyhydrogen burner, at which point the generated fine glass particles (soot) are deposited on the tip of the starting material to produce a porous preform. As the porous preform can be grown in the axial direction by lifting the starting material upward, large preforms are capable of being fabricated. The porous preform becomes a transparent glass preform through processes of high purification by heating in a dehydrating gaseous atmosphere, and then making transparent by heating at even higher temperatures.

Many difficulties were encountered in the early days, including deformation or cracks in the porous preform during deposition and the formation of bubbles during the transparency process. The members of the joint research team worked day and night to solve these problems, leading to an important first step toward the completion of the VAD method. As such, the joint research team laid the foundation for fiber optic communications in Japan.

After 1978, improvements in dehydration techniques for the VAD method brought rapid progress to the development of low-loss optical fibers. A transmission system using GI fiber*1 developed as a result of this was then adopted in 1982 for actual use following commercial testing in 1980.

Development of SM fiber*2 using the VAD method was then advanced in anticipation of the future need for high-capacity, long-distance transmissions. Although the technical challenge was significant due to having a thinner core than that of GI fiber, the VAD method came to surpass other methods in terms of both its properties and productivity as a SM fiber manufacturing method, thanks to the results of various innovations including the improved structure of a soot depositing burner for stable growth of the thin core. The culmination of the joint research’s achievements was the construction of a trans-Japan fiber optic trunk line connecting Asahikawa and Kagoshima from 1983.

In 1981, when the commercialization of optical fibers and cables was first witnessed, Sumitomo Electric established the Fiber Optics Development Division, which was renamed the Fiber Optics Division in 1984.

Sumitomo Electric engineers continued to take up new challenges in fiber optics after the expiration of the joint research agreement in 1983, and VAD technologies remain the foundation of Sumitomo Electric's optical fiber technology to this day. In addition to Sumitomo Electric, nearly 60% of the world's optical fiber preforms are manufactured using the VAD method now. The VAD method developed in Japan has today spread around the world and was even recognized as an internationally prestigious IEEE Milestone in 2015.

Popularization Period: 1984-1990

Fierce Competition in Development

Sumitomo Electric’s World-class Technology and Know-how Light up the Seafloor

The stage was now set for the unfolding of fierce competition among manufacturers.

Sumitomo Electric took on the wholly-synthesized VAD method, in which a glass layer is synthesized around the dehydrated and transparent preform by another cycle of the VAD process. With the wholly-synthesized VAD method, the preform size could be increased dramatically, leading to an expected improvement in productivity. In the mid-1980s, low-loss, high-strength optical fiber was realized through the wholly-synthesized VAD method, and was introduced in the trans-Pacific submarine optical cable (TPC-3), which came into service in 1989.

For all optical fiber engineers, low transmission loss presented the ultimate challenge. Optical fiber has a double-layered structure, consisting of a core, which is the pathway for light, and the cladding around it. For propagating light in the core, a refractive index difference between the core and cladding is necessary. In conventional optical fibers, germanium is doped to increase the refractive index of the core. However, germanium doping is not preferred due to purity concerns. Aiming for even lower transmission loss, the engineers then arrived at a change of viewpoint. By choosing pure silica as the core material for high transparency, and doping fluorine to the cladding to lower its refractive index, a pure-silica core optical fiber (PSCF) was created.

This idea had already been conceived in the 1970s – an early stage of optical fiber development. In the early 1980s, a fluorine-doping technique was developed, in which the porous preform produced by the VAD method was heated in a fluorine-containing atmosphere, making it realize a PSCF. Sumitomo Electric achieved a world record with the lowest transmission loss of 0.154 dB/km with a PSCF in 1986, compared to the conventional value of 0.20 dB/km.

The next issue that emerged was chromatic dispersion.*3 Chromatic dispersion causes optical signal distortion. This limits the transmission distance in the 1.55 µm wavelength band, where transmission loss is at a minimum, in standard SM fibers. Therefore, a dispersion-shifted fiber with zero chromatic dispersion in the 1.55 µm band was required. This fiber could extend repeater intervals, which had previously been limited to around 40 km, to more than 100 km, and it was applied to a 120 km submarine optical cable between Oita and Matsuyama in Japan in 1987. Moreover, NTT fully adopted this fiber in their terrestrial trunk lines from 1988 onward.

Sumitomo Electric started to expand its business overseas in the early 1980s, when the superiority of the VAD method was recognized globally.

[Technical Terms]

*1) GI fiber (Graded-index fiber)

A type of multimode fiber in which the refractive index profile of the core is parabolic. Since core diameters of GI fibers are as large as 50 μm, they are relatively easy to connect to light sources and receivers.

*2) SM fiber (Single mode fiber)

An optical fiber with a core diameter of about 10 μm that can propagate only a single mode. Since there is no interaction with other modes, high-speed and long-distance optical signal transmission is possible.

*3) Chromatic dispersion

A phenomenon in which the velocity of an optical signal propagating through an optical fiber differs depending on its wavelength. A single optical signal contains components with slightly different wavelengths each propagating at a different velocity, which brings distortion of the optical signal waveform. This distortion increases as the transmission distance increases.