Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form. To delete your registration, please visit here.

October 2021 No.93

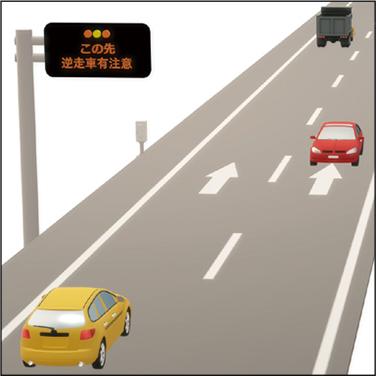

In recent years, serious accidents caused by wrong-way driving on expressways have become a problem. Expressway administrators have taken measures to prevent vehicles from running the wrong way particularly at entrances and exits, but no effective measures have been taken on the main lanes. We have developed software that detects wrong-way driving vehicles using the loop-type vehicle detectors already installed on expressways. Further, we have developed a system that notifies the expressway control center when a wrong-way driving vehicle is detected. In this paper, we present the false detection suppression algorism that has been field tested to improve accuracy, and report on the results of accuracy evaluation of the detection system.

1.3 MB

1.3 MB

Due to the rapid growth of internet traffic, the transmission capacity of optical coherent communication is about to reach 800 Gbit/s. Photodetectors for coherent receivers are required to have three key features: wide frequency bandwidth to support 100 GBaud operations, high responsivity to mitigate the power consumption of local oscillators, and multifunctional integration to reduce footprint and cost. We have developed a wide-bandwidth and high-sensitivity InP-based optical mixer-integrated photodetector that can be installed in an 800 Gbit/s coherent receiver, and a multifunctional integrated photodetector that enables the downsizing and cost reduction of coherent receivers.

1.5 MB

1.5 MB

The rapid growth of optical network traffic has dramatically increased the demands for high-density optical interconnects in data centers. To realize high-density multi-channel optical connections with easy handling, single-fiber connectors with multi-core fibers (MCFs) are expected. In this paper, we present a new type of LC-interface MCF connector. The connector has passed the Telcordia GR-326-CORE reliability test and achieved low insertion loss compatible with IEC 61753-1 Grade B for low-loss SMF connectors.

3.1 MB

3.1 MB

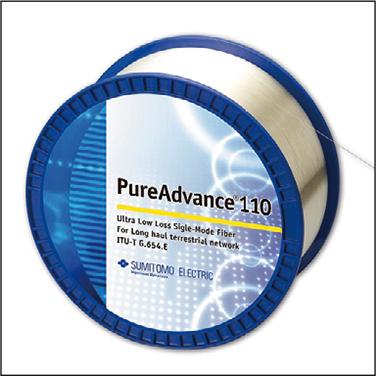

We have developed “PureAdvance,” a low-loss and low-nonlinearity pure silica core fiber complying with ITU-T G.654.E, and started supplying it for terrestrial long-haul networks. The excellent practicality of PureAdvance, including reliable terrestrial cabling, low splice loss, and stable Raman amplification, have been demonstrated for actual deployment as terrestrial links. Transmission systems using PureAdvance exhibit higher transmission performance than those with SSMF or NZDSF, making PureAdvance ideal as a transmission medium to support long-haul, high-capacity terrestrial applications including telecom trunk lines, datacenter interconnection, and transmission lines between submarine landing stations and datacenters.

1 MB

1 MB

With the ever-increasing demand for reducing the environmental impact, there is a need for overhead transmission lines that can reduce transmission loss. We have been working to improve the conductivity of aluminum alloys for overhead transmission lines. This time, by improving the alloy composition and processing methods, we have developed a new thermal-resistant aluminum alloy wire with an allowable continuous operating temperature of 150°C and high conductivity of 61%IACS. In this paper, we introduce the development of the aluminum alloy wire and the characteristics of overhead transmission lines using the new wire.

2 MB

2 MB

With the expansion of the use of renewable energy, it is necessary to construct not only AC distribution systems that connect renewable energy power plants to the existing grid but also long-distance large-capacity DC transmission lines. The AC cable systems are prone to various problems such as AC harmonic resonance and current zero missing, which require designs based on power system simulation. The large-scale DC transmission lines are expected to play an important role as multi-terminal transmission systems in the future, and their electrical system design and submarine route design require advanced cable technology. This paper reports on our new cable system design methods for AC distribution lines and DC transmission lines that contribute to the increasing use of renewable energy.

3.3 MB

3.3 MB

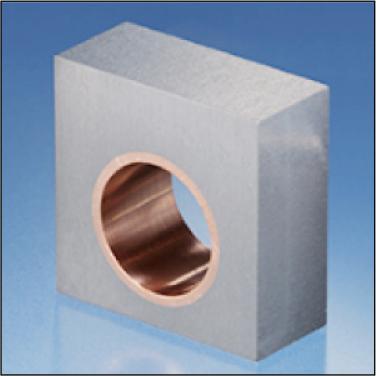

The ITER project is being promoted as an international megaproject to scientifically and technically demonstrate the feasibility of fusion energy, which is one of the most promising candidates for achieving a decarbonized society. Among the components of ITER, tungsten (W) is used for a divertor, which is exposed to ultra-high temperatures above 2000°C. For stable operation of ITER, W is required to exhibit excellent thermal shock resistance under a high-temperature heating/cooling cycle. In this study, we have newly developed a W with an improved thermal shock resistance by suppressing the grain growth due to high temperature. Using the developed W, monoblocks were fabricated for small-scale mock-ups and plasma facing unit (PFU) prototypes, and their performance was evaluated by high heat flux test (HHFT) simulating a fusion reactor. HHFT results showed that no cracks occurred even under severe conditions. In particular, the evaluation results of the prototype greatly exceeded the requirements of ITER, and the developed W was certified as “unbreakable tungsten” for the first time in the world.

3.4 MB

3.4 MB

High-performance F-theta (Fθ) lenses are applied to CO2 laser drilling machines of printed wiring boards to drill micro-via holes with high precision, high speed, and high throughput. They are generally made of zinc selenide (ZnSe) or germanium (Ge), but Ge is more temperature sensitive and has higher absorption than ZnSe. Therefore, as laser power increases, deterioration in the stability and quality of laser drilling tends to occur. Taking advantage of our strength as a comprehensive optics manufacturer that produces a complete range of products from ZnSe materials to finished laser optics products, we have developed a new F-theta lens using ZnSe for all lens elements and a cover window with a diamond-like carbon (DLC) coating. Here, we provide the technical outline of the development

2.9 MB

2.9 MB

In steel machining, particularly in the automotive industry, various efforts are being made to reduce the environmental impact and to use resources efficiently. We released the AC8000P series for steel turning in 2016, which uses the new chemical vapor deposition (CVD) coating technology “Absotech Platinum,” and are continuously expanding the product lineup. Meanwhile, there is a strong need for cutting tools that demonstrate a long tool life and stable performance. To satisfy these demands, we have developed a new steel turning carbide grade, AC8020P, which shows excellent wear resistance and chipping resistance in high-efficiency machining. Together with the existing AC8000P series, the new AC8020P will reduce machining costs in a wide range of steel turning operations.

2.8 MB

2.8 MB

We have been developing the iDS coating system series with improved productivity and film performance since 2012 by reviewing the conventional coating systems from the basics. The iDS series has increased compatibility with a variety of applications by expanding the lineup of chamber sizes. This time, we have developed and launched iDS-720, which is suitable for mass production of tools and manufacturing of large punches and dies.

3.3 MB

3.3 MB

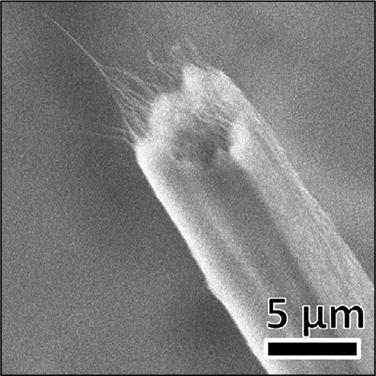

We have been focusing on carbon nanotubes (CNTs) as a material for next-generation electric wires that are lighter and more conductive than copper and aluminum wires. CNT single fiber has a greater conductivity than copper and the highest tensile strength of any known material. Aiming at the practical application of CNT electric wires, we have discovered the effectiveness of applying tensile stress to CNTs during the growing process from iron catalysts. In addition, at the University of Tsukuba, where a joint research was conducted, the growth of centimeter-class single fibers was observed in high-speed airflow, suggesting that stress applied during the growth contributes to the lengthening of CNTs. Using this principle as a basis for the growth method, we have created a metric-class CNT yarn that aggregates these long CNT single fibers. The new yarn has several times the strength of the conventional CNT yarn and exceeds the tensile strength of commercially available carbon fibers. This yarn will not only replace carbon fibers but also create new applications that have never been seen before.

3.4 MB

3.4 MB

Magnesium alloys have the lowest density of all practical metals. Our AZ91 magnesium alloy sheets are used for thin and light laptop computer bodies due to their superior strength and corrosion resistance in addition to their lightweight. In the electronics industry, 5G devices are being implemented to take advantage of IoT or AI, which can cause heat generation in electronic devices. One of the solutions to this is to improve the thermal conductivity and heat dissipation of the device bodies. In this paper, we introduce a new magnesium alloy sheet, SMJ140, having thermal conductivity in a range from 120 to 140 W/(m·K). These values are doubly higher than that of the AZ91 sheet. The heat dissipation of the SMJ140 is similar to that of a commercial aluminum alloy sheet A5052.

3.3 MB

3.3 MB

In 2030, Japan will enter a super-aging society where one in three people will be 65 years old or older. In a social environment, where all kinds of services are changing with the rapid digitization, elderly people with low IT (information technology) literacy are isolated from society. In addition, the aging of supporters who take care of the elderly in the community and the shortage of those supporters have become major social issues. In addition, the prolonged pandemic of COVID-19 has led to a new problem of the elderly becoming isolated due to the lack of face-to-face contact. In the field of welfare, where people support people, the need for IT-based non-contact monitoring systems is expected to grow further in the future. This paper introduces the joint research that Nissin Systems Co., Ltd. has conducted with the Kurobe City Council of Social Welfare in Toyama Prefecture since 2019, based on the company’s concept of “Anyone can easily connect with the community.” The authors present an ICT (Information and Communication Technology) terminal that was developed in the research project for the elderly at home and the support services using the terminal.

2.4 MB

2.4 MB

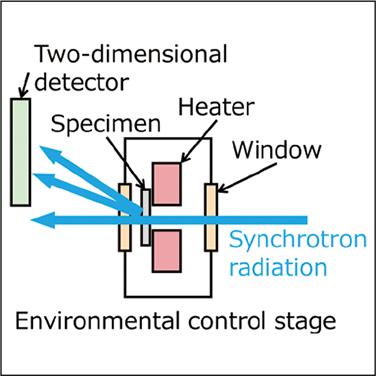

The properties of electric wires made of copper and aluminum are largely affected by the temperature and time of heat treatment. In order to optimize heat-treatment conditions, we have developed an in-situ measurement technique that uses synchrotron X-rays, which have high transparency and intensity. While this technique is expected to reduce measurement and analysis time, its application to actual operation has been limited due to the opportunities for measurement and the time required for data analysis. In this paper, we report new environmental control systems at our synchrotron beamline in SAGA-LS and a newly developed program for the automatic analysis of large amounts of data. We have confirmed that the in-situ measurement of copper and copper alloys is possible and the difference in softening behavior can be analyzed in a short time.

1.9 MB

1.9 MB

Conventionally, halogen lamps have been used for automotive headlamps and rear lamps. Recently, however, LED lamps have been increasingly used due to their long service life, low power consumption, and quickness to attain maximum brightness. Regarding the internal structure of in-vehicle LED lamps, an LED lamp and a driver module are built into the housing, as shown in Fig. 1. Automotive low-voltage electric wires are used for the wiring. Electric wires used in LED lamps must have anti-fogging characteristics to prevent fogging of the glass over long-term use. However, the electric wire covering causes fogging of the glass due to outgassing after a long period of use. Thus, the electric wire covering used for wiring in LED lamps must have low outgassing properties. This paper introduces our newly developed insulation material with low outgassing properties derived from our proprietary blending technology.

273 KB

Electric vehicles (hereinafter “EVs”) and quick chargers have come into widespread use around the world toward achieving a decarbonized society. Sumitomo Electric Industries, Ltd. is supplying EV charge Cable with Connector “CHAdeMO conformity” for Quick Charger in the global market to connect EVs with quick chargers. SEVD-11 and SEVD-02, which are supplied by Sumitomo Electric, are shown in Photo 1, and their basic characteristics are shown in Table 1.

0.6 MB

Copyright of the paper contained in SUMITOMO ELECTRIC TECHNICAL REVIEW belongs to Sumitomo Electric Industries, Ltd.

The paper is to be used solely for private, reference purpose, and reproduction without the permission of the copyright holder is prohibited.

Meet the Authors of the SUMITOMO ELECTRIC TECHNICAL REVIEW

We at Sumitomo Electric Group are driven to pursue technological innovations to create value for a better world.

Learn more