Development History

Episode of Development for POREFLON

The history leading to the development of the innovative POREFLON water treatment stretches back over 50 years. This is the story of how Sumitomo Electrics knowledge and passion came together to help solve the world’s water problems.

episode 1: POREFLON, a proprietary material with a 50-year history

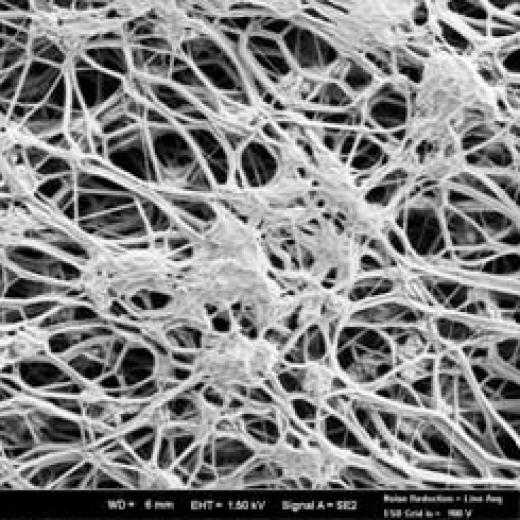

POREFLON is an innovative porous material manufactured by SEI from 100% PTFE with first patent on its PTFE expanding technology in 1962. POREFLON has four important features. Excellent chemical resistance to acids, alkalis and solvents surpass that of PVDF or PE. Robustness allowing prolonged period of use. The highest porosity among competitive membranes and high water permeability. And heat resistance that allows membrane filtration even at up to 200°C.

episode2: Water is a key to the future of POREFLON!

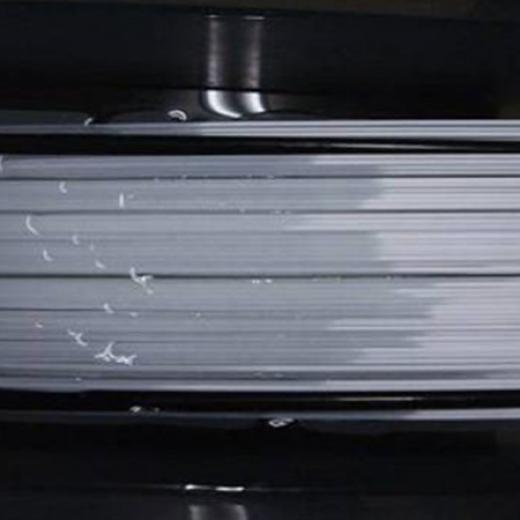

The new prototype employed a composite structure with a hollow fiber membrane with large pores and good permeability wrapped with an ultrathin layer with small pores. The outer membrane had a pore size of 0.1 μm, while the inner membrane pores were 2μm, for an overall porosity of 80%. This PTFE composite hollow fiber membrane offered both high strength and flow rate. Successive improvements increased the flow rate nearly four-fold while decreasing the cost to one-fourth that of previous products.

episode 3: POREFLON used in major construction in Korea

After progress of the technology, a businessman who was interested in POREFLON started marketing in Korea. Water treatment system builders at that time were also developing technology and testing modules from competitors, but they could not meet the performance requirements. When Daewoo E&T, a major Korean construction company, decided to incorporate SEI's POREFLON water treatment membrane module in several sewage treatment plants in Sinpyeong, it was clear that POREFLON’s time had arrived.

The water treatment modules for the Sinpyeong sewage treatment plant needed to handle a daily sewage of about 10,000 m³, a totally different scale than the prototypes. Initially, the flow rate of the modules did not reach the targets, due to the overall assembly structure. A manual trial and error approach was used to find out the optimal structure. All of this hard work led to the successful development of POREFLON membrane modules for a large-scale commercial plant.