Featured Stories

VRFBs: A Sustainable Solution for Long-Duration Energy Storage

As the global energy landscape shifts towards renewable sources, the demand for efficient, safe, and sustainable energy storage solutions has never been greater. Vanadium Redox Flow Batteries (VRFBs) have emerged as a promising long-duration energy storage solution, offering exceptional recyclability and serving as an environmentally friendly battery alternative in the clean energy transition.

◇ The Sustainability Edge of VRFBs

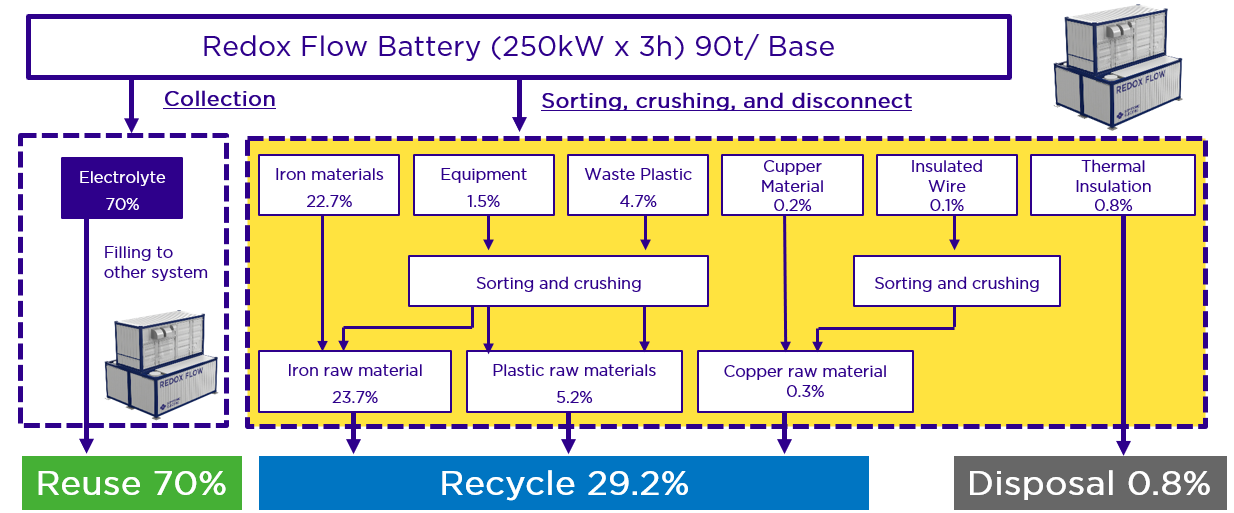

VRFBs stand out in the energy storage sector due to their unique design and use of vanadium electrolyte. The electrolyte, which does not degrade over time, can be reused across multiple systems, contributing to high sustainability. Sumitomo Electric’s VRFBs, for example, achieve a recyclability rate of up to 99.2%, with 70% of the electrolyte reused and 29.2% of components recycled, leaving only 0.8% for disposal.

Moreover, VRFBs are non-flammable and operate safely across a wide temperature range, minimizing risks associated with thermal runaway, a concern prevalent in some other battery technologies. Their long operational lifespan, up to 30 years with minimal capacity degradation, further enhances their sustainability profile.

◇ Challenges in Lithium-Ion Battery Recycling

While lithium-ion batteries are widely used for energy storage, their recycling infrastructure and circularity remain limited. The International Energy Agency (IEA) reported in 2023 that global lithium-ion battery recycling capacity exceeded 300 GWh, yet over 80% is concentrated in China, with less than 2% in North America and Europe.

According to a 2024 World Economic Forum study, only around 50% of retired lithium-ion batteries are collected for recycling, with many stockpiled, exported, or discarded. Industry experts such as Hans Eric Melin estimate that just 5–10% of batteries are actually recycled in practice.

These challenges came into sharp focus in January 2025, when a high-profile lithium-ion battery recycler filed for bankruptcy protection in both Canada and the U.S. As reported by Reuters and Canary Media, the company cited cost overruns and engineering delays at its Rochester, New York, plant. Despite receiving substantial public funding and being positioned as a key player in North America’s battery recycling strategy, its financial failure revealed the technological, economic, and operational complexity of lithium-ion recycling at scale.

While lithium-ion batteries offer high energy density and widespread use, their end-of-life treatment remains fragmented and resource-intensive, particularly components like electrolytes, separators, and binders that are rarely recovered. In contrast, technologies like vanadium redox flow batteries (VRFBs) rely on reusable liquid electrolytes and recyclable hardware, enabling a more robust and predictable pathway toward circular energy storage.

◇ Supporting Studies and Industry Insights

• Long-term durability: A commercial-scale VRFB evaluated over a decade demonstrated exceptional electrolyte stability and minimal capacity fade (Li et al., 2024). These findings align with other peer-reviewed research showing high efficiency and consistent output over 20+ years of operation (ACS Sustainable Chemistry & Engineering, 2021).

• Recyclability and circularity: Vanadium electrolyte is not only stable but also recoverable and reusable, as evidenced by U.S. Vanadium’s 97% recovery rate from decommissioned systems. Research in ScienceDirect further validates the recyclability of key components including membranes and carbon felt electrodes.

• Life cycle assessments: Studies by the California Energy Commission (2021) and Journal of Industrial Ecology (Blume et al., 2022) highlight that while manufacturing impacts (e.g. vanadium processing) can be significant, they are outweighed over time by long lifespan, reusability, and minimal degradation.

• Real-world example: Sumitomo Electric has reused electrolyte across two decades of commercial deployments—demonstrating practical circularity, from a customer system (2001–2011) to continued operation at Yokohama Works since 2012.

While VRFBs offer significant sustainability advantages, they are not without limitations. Their lower energy density compared to lithium-ion batteries makes them less suited for mobile or space-constrained applications. In addition, the initial capital cost can be higher, though this is often offset by longer system life and lower maintenance needs. Some environmental impacts associated with vanadium extraction and membrane manufacturing have also been noted in LCA studies, underscoring the importance of responsible sourcing and ongoing material innovation. Nonetheless, for stationary, long-duration energy storage where safety, recyclability, and total lifecycle performance matter most, VRFBs remain a highly compelling option.

◇ Conclusion

In the pursuit of sustainable and reliable energy storage solutions, Vanadium Redox Flow Batteries offer a compelling combination of safety, longevity, and recyclability - key attributes of any truly environmentally friendly and long-duration energy storage technology. As the energy sector continues to evolve, embracing technologies like VRFBs will be crucial in achieving environmental goals and ensuring a resilient energy infrastructure. As policymakers and industry leaders seek long-term, sustainable energy strategies, VRFBs present a practical and future-ready option that aligns with both environmental and economic priorities.

Reference:

Blume, N., Becker, M., Turek, T., & Minke, C. (2022). Life cycle assessment of an industrial‑scale vanadium flow battery. Journal of Industrial Ecology, 26(5), 1796–1808. Retrieved from https://doi.org/10.1111/jiec.13328

California Energy Commission. (2021). Life Cycle Assessment of Emerging Battery Technologies for Stationary Energy Storage. CEC-500-2021-051. Retrieved from https://www.energy.ca.gov/sites/default/files/2021-12/CEC-500-2021-051.pdf

Canary Media. (2024, May 23). Li-Cycle’s quest to recycle lithium-ion batteries ends in bankruptcy. Retrieved from https://www.canarymedia.com/articles/recycling-renewables/li-cycles-quest-to-recycle-lithium-ion-batteries-ends-in-bankruptcy

International Energy Agency. (2023). Global EV Outlook 2023. Retrieved from https://www.iea.org/reports/global-ev-outlook-2023

Li, Y., Kienbaum, D., Lüth, T., & Skyllas-Kazacos, M. (2024). Long Term Performance Evaluation of a Commercial Vanadium Flow Battery System. SSRN. https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4753805

Melin, H. E. (2023). Recycling lithium-ion batteries: Status, challenges and outlook. Retrieved from https://www.linkedin.com/pulse/recycling-lithium-ion-batteries-hans-eric-melin/

Reuters. (2025, May 15). Li-Cycle files for bankruptcy protection in Canada and U.S. Retrieved from https://www.reuters.com/world/americas/battery-recycler-li-cycle-files-bankruptcy-protection-canada-2025-05-15/?

Sumitomo Electric Industries. (n.d.). Electrolyte Recycling for VRFBs. Retrieved from https://sumitomoelectric.com/products/flow-batteries/electrolyte-reuse

U.S. Vanadium. (2022). Technical Summary: Reprocessing and Recovery of Vanadium Electrolyte from Decommissioned VRFB Systems. Retrieved from https://usvanadium.com/u-s-vanadium-successfully-recycles-electrolyte-from-vanadium-redox-flow-batteries-at-a-97-recovery-rate/

Wang, Q., Li, Y., Chen, X., Yang, Y., & Zhang, H. (2024). Sustainable recycling and regeneration of redox flow battery components. Journal of Energy Chemistry, 94, 244–259. Retrieved from https://www.sciencedirect.com/science/article/pii/S2950264025000231

World Economic Forum. (2024). The lithium-ion battery end-of-life market: A baseline study. Retrieved from https://www3.weforum.org/docs/GBA_EOL_baseline_Circular_Energy_Storage.pdf

Follow us on LinkedIn!

If you enjoyed this Feature Story, be sure to follow Sumitomo Electric U.S.A on LinkedIn. We share updates there whenever new stories are published. (Note: Sumitomo Electric Group also has a global LinkedIn account for corporate updates.)