Sumitomo Electric Launches Technology Development on AI-based Defect Detection of Products with DATAGRID Inc.

— Promoting digital transformation at manufacturing sites

to strengthen manufacturing —

At Sumitomo Electric, the IoT R&D Center (established in 2017) has taken the initiative to improve productivity and safety using IoT/AI technology toward promoting digital transformation at manufacturing sites. As part of such efforts, the company has been working on the development of defect detection AI to automate the appearance inspection of products conducted by skilled workers. However, to train the defect detection AI to attain advanced detection capabilities, it is necessary to prepare a large amount of training data that covers various patterns. Collection of training data requires considerable time and cost. This is why the defect detection AI has not been fully utilized by manufacturers, including Sumitomo Electric.

This project aims to develop AI capable of defect detection comparable to that of skilled workers even if only a very small amount of real training data is available.

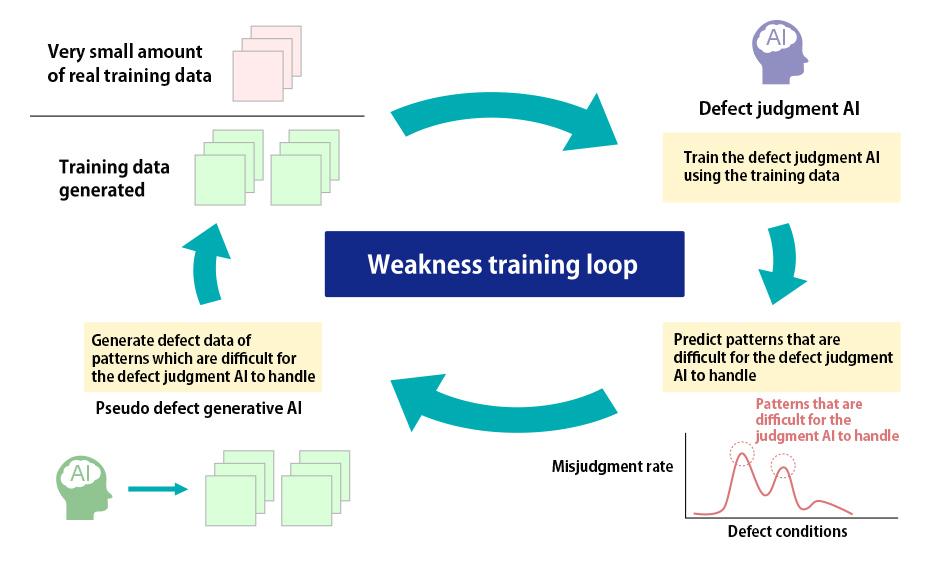

Sumitomo Electric’s defect detection technology is used to predict patterns that are difficult for the AI to handle and cause misdetection, and DATAGRID’s pseudo-defect generative technology is used to generate defect data that are difficult for the AI to handle. The project also aims to overcome difficult patterns by repeatedly applying the technology to overcome difficulties by training (anti-weakness training loop), in which the defect detection AI is retrained using data generated, and thereby increase the accuracy of the defect detection AI.

Q.What is noteworthy about this joint technology development project?

The technology to achieve coordinated training of the defect detection AI and the pseudo-defect generative AI has not been established. This would be the world’s first such technology if we could develop it.Students take mock examinations to identify their weak subjects and intensively study those subjects to efficiently increase their scores.

Likewise, this technology is expected to increase the development speed of the defect detection AI by tens or hundreds of times by allowing a computer to repeat the anti-weakness training loop automatically. The technology to overcome difficulties through training is also effective for various data, including time series data, in addition to image data. It can be applied to various processes at manufacturing sites, such as automation of the appearance inspection process, failure prediction of equipment, and inventory control. Thus, the technology is expected to accelerate automation at manufacturing sites. We will take advantage of these technologies to improve the manufacturing capabilities.