A.L.M.T. Corp. Wins a Contract to Supply a Component Developed for the Fusion Experimental Reactor ITER

– International Project Attracting Attention as a Solution to Energy and Environmental Problems –

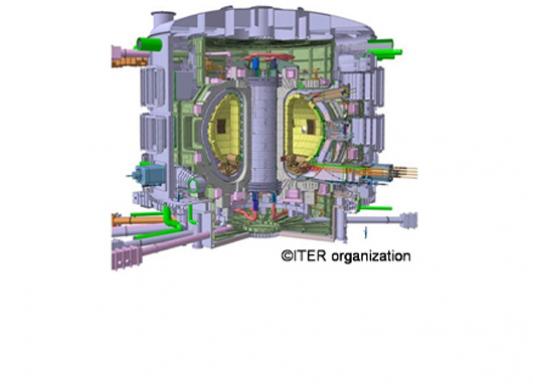

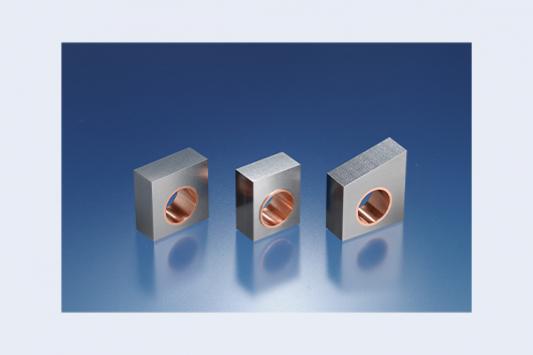

As global momentum to realize a carbon-free society is growing, “fusion power generation” is attracting attention as a fundamental solution to energy and environmental problems. Nuclear fusion is a reaction in which light nuclei combine to form a heavy nucleus, and the sun produces energy through this phenomenon. With the aim of producing fusion energy on the ground and using it for power generation, research and development of fusion power generation is underway. Unlike nuclear power generation, which uses fission reactions, fusion power generation does not generate high-level radioactive waste and the fusion reaction can be stopped easily. Due to these safety characteristics, its realization is highly anticipated. Under such circumstances, the construction of the fusion experimental reactor ITER is underway in France with international cooperation among six countries and one region (Japan, the EU, the United States, Russia, India, China, and South Korea). Recently, the tungsten monoblock developed and manufactured by A.L.M.T. Corp., a Sumitomo Electric Group company, has been adopted as an important component of the divertor,* a key device in the ITER.

* Divertor: A device for receiving high heat flow and particle flow generated by plasma and discharging and removing impurities unnecessary for maintaining plasma.

In the process of fusion power generation, nuclear fusion reactions, which act as the energy source, take place in a plasma exceeding 100 million degrees Celsius confined in a magnetic field. Since the surface temperature of the divertor reaches a maximum of 2,300 degrees Celsius, the materials of the fusion reactor are required to have extremely high heat resistance. The tungsten monoblock developed and manufactured by A.L.M.T. Corp. has been confirmed to have characteristics that suit the fusion reactor, withstanding a thermal load of more than 2,000 degrees Celsius and remaining unbreakable even for a period of more than three times the number of operation cycles required in the specifications of the ITER, which led to the award of the contract this time.

As there is growing need for the stable supply of environmentally friendly clean energy, the “unbreakable tungsten” developed by the Sumitomo Electric Group is expected to contribute to the realization of fusion power generation.

The Sumitomo Electric Group will continue to contribute to solving social issues through its innovative products and technologies.

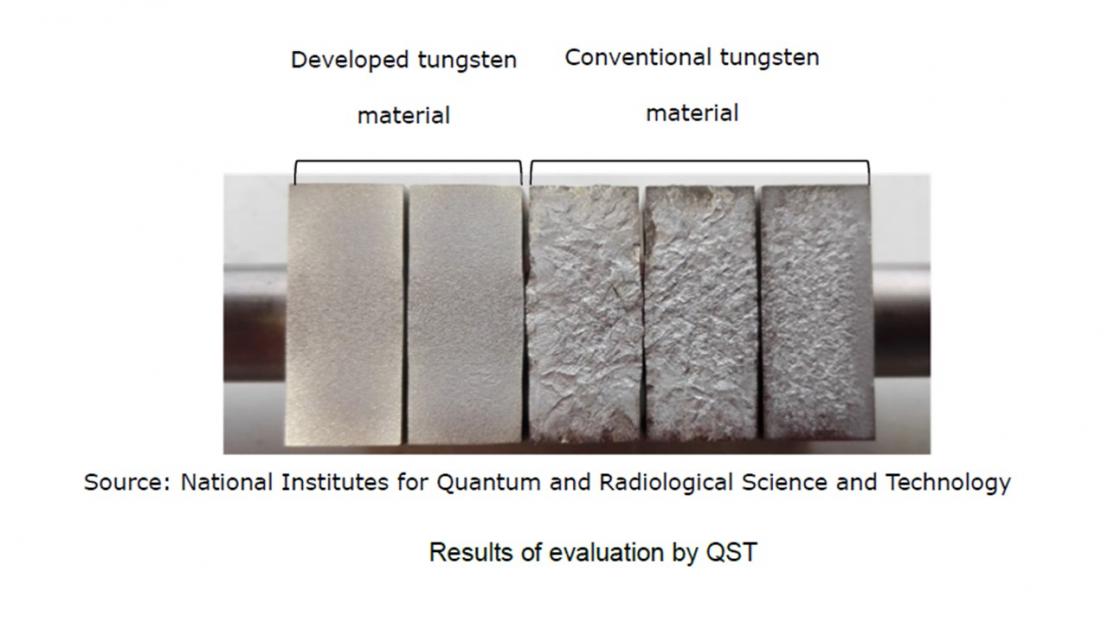

Results of evaluation by the National Institutes for Quantum and Radiological Science and Technology (QST)

It was confirmed that the developed tungsten material has excellent thermal stability since it exhibited no remarkable elevation of the surface due to deformation, unlike the conventional tungsten material.

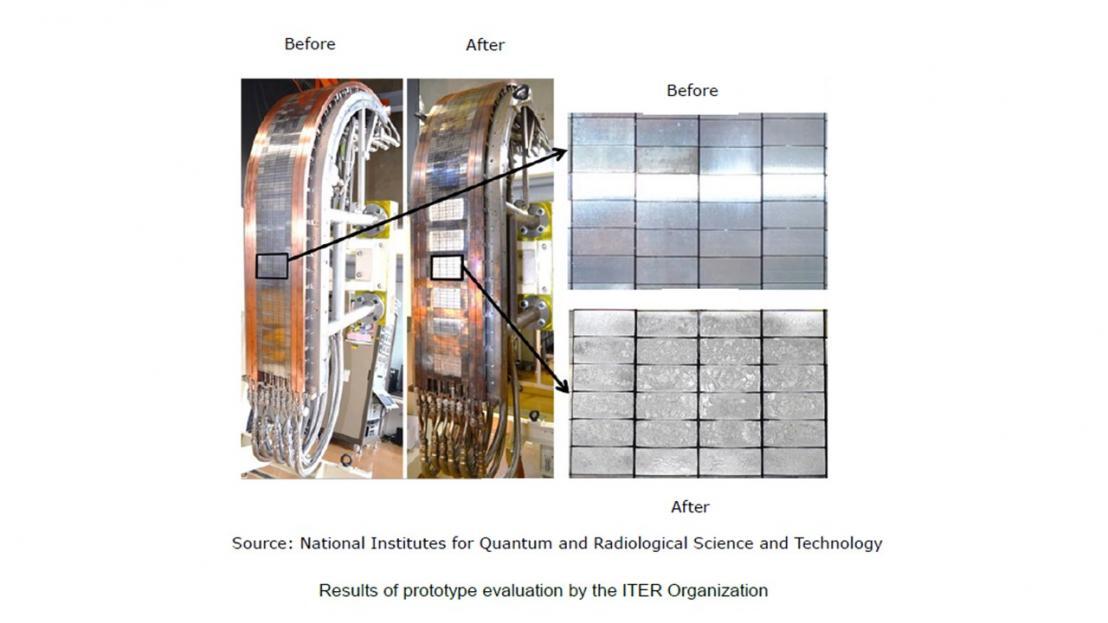

Results of prototype evaluation by the ITER Organization

The prototype exhibited excellent thermal shock resistance since no cracks were observed even for an evaluation period of more than three times the number of operation cycles required in the specifications of the ITER.