Contributions of Celmet™ to the Realization of a Decarbonized Society

Focusing on “fuel cells” and “hydrogen production systems”

Efforts to gain customers for fuel cells and hydrogen production systems

At the forefront of sales operations are three members of the Celmet Group, Energy Devices Sales Div. of Sumitomo Electric. Masaki Yamaji, who is the head of the group, has been working on CelmetTM for seven years. He pointed out that the business has entered a new phase.

“The commercial value of CelmetTM has improved thanks to support from many customers, including in-vehicle battery manufacturers. We will continue to ensure the stable supply of products that meet customers’ needs and contribute to their production activities. In line with the decarbonization trend, efforts have been accelerated to promote the social implementation of hydrogen energy. Our new mission is to work with the R&D staff and gain customers for our fuel cells and hydrogen production systems,” said Yamaji.

To accelerate product development, the New Business Development Section was established at Sumitomo Electric Toyama in 2022. Meanwhile, the Sales Group, including Yamaji, launched overseas promotion activities by revamping the CelmetTM website and through digital marketing. At present, more than 100 inquiries are received annually, and the number of promising projects has been increasing at customers, mainly hydrogen production system manufacturers.

Making proposals globally in collaboration with overseas group companies

Yumie Kikuchi and Erina Hagihara, who are in their sixth year and third year at the company, respectively, are in charge of sales of CelmetTM with Yamaji. They contact manufacturers of fuel cells and hydrogen production systems.

Kikuchi, who is in charge of sales in Japan, said: “It is crucial to identify the needs of hydrogen production system and fuel cell manufacturers in Japan as the manufacturing methods and required product properties, including high thermal resistance and long service life, vary. If a customer needs an alloybased CelmetTM derived by material modification, we develop a new CelmetTM in collaboration and cooperation with the R&D Group to meet the requirements. We need to work as a partner of manufacturers, not as a supplier. This gives me a sense of fulfillment.”

On the other hand, Hagihara is in charge of sales overseas, where the market for hydrogen production systems is ahead of Japan's domestic market. The company seeks to be designed into systems at an early stage. Last year, they made progress in negotiations with a new business partner. “The customer is an Israeli manufacturer that became interested in our products after we responded to their inquiry. Following a plant tour of Sumitomo Electric Toyama, we coordinated the specifications. Eventually, we received an order to fabricate a prototype. We must not assume a passive attitude in overseas sales. We hold workshops and share information so that respective group companies can take the initiative in activities through the overseas sales network. We were able to receive the order in cooperation with a sales company in Europe,” said Hagihara.

At present, the profile of CelmetTM is not high. Sumitomo Electric Toyama will actively access promising markets and propose competitive applications both on the web and through participation in overseas exhibitions.

Huge potential of Celmet™

It is interesting to know how CelmetTM has survived. Demand for Ni-MH batteries decreased in the 2000s when Li-ion batteries started to gain market share. It was often expected that production of and demand for CelmetTM would decline. However, the business has overcome difficult situations and recovered from a temporary setback each time. Managing Executive Officer Hidetoshi Saito, who has experienced these developments, sees huge potential for CelmetTM in the future.

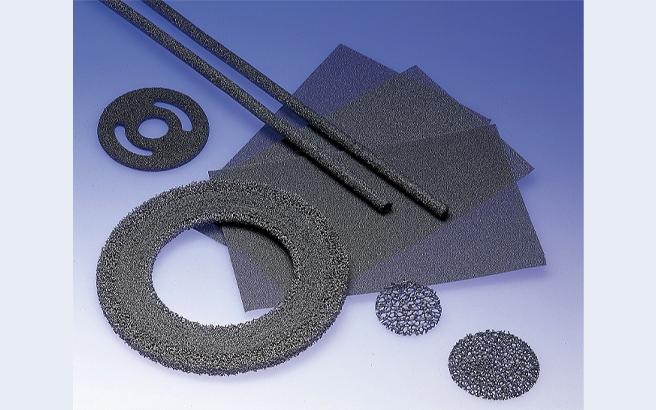

“Li-ion batteries installed in electric vehicles (EVs) are highly regarded for their high energy efficiency and high capacity. However, they are not the ultimate solution and are deployed as a makeshift measure. Li-ion batteries pose safety concerns and are inferior to Ni-MH batteries in terms of durability. All-solid-state batteries, which will replace Li-ion batteries, are under development, to which CelmetTM is highly likely to be applicable. In the future, fuel cell vehicles (FCVs), which drive by generating electricity through a chemical reaction between hydrogen and oxygen, are also expected to increase in addition to EVs. CelmetTM is useful in all steps of hydrogen use. It can be used not only for fuel cells but also for catalyst supports for the production, transport, and storage of hydrogen. I am convinced that CelmetTM will contribute significantly to a hydrogen society in the future,” said Saito.

Saito gave an encouraging message to younger employees. “I expect that you will do your utmost in your work. This will provide you with new findings and enable you to experience the joy of work through personal development. The Sumitomo Electric Group also has a culture where other members support you when you face a difficulty. I hope you will further develop the CelmetTM business with other members,” said Saito.

Nurtured by the predecessors of the Sumitomo Electric Group, CelmetTM has marked its 50th anniversary. How will CelmetTM be passed on over the next 50 years? The future deployment of CelmetTM toward the next generation deserves your attention.

“We will continue to ensure the stable supply of CelmetTM depending on customers’ needs and meet the expectations of our customers, including manufacturers of in-vehicle batteries. Hydrogen-related fields have huge potential, so we will achieve further growth of CelmetTM by offering new value.”

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.