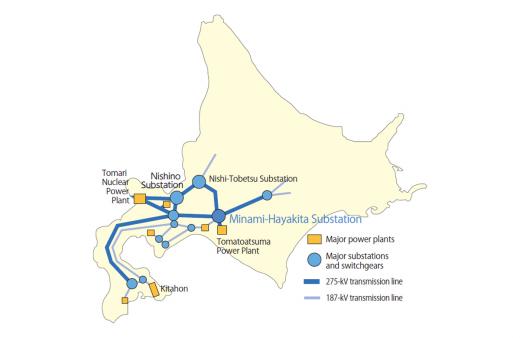

Grid Storage Batteries for Power Supply Stabilization– Minami

Hayakita Substation, Hokkaido Electric Power Network

The meaning in introducing grid storage batteries

Abira-cho, Yufutsu-gun, Hokkaido: the operation of grid storage batteries (redox flow batteries) was started in April 2022 at the Minami-Hayakita Substation of HEPCO Network. A broad field having dimensions of about 150 m × 45 m and bristling with around 40 redox flow battery facilities is spectacular. The capacity is 17 MW × 3 hours = 51 MWh. It is one of the largest redox flow battery systems in the world.

Since the amount of renewable energy generation from solar and wind farms reached the interconnectable capacity in Hokkaido, many renewable energy companies have installed storage batteries at their sites to independently decrease the output variations of wind and solar power generation. However, these batteries were installed on the power grid side by the power grid company. The installation of large storage batteries on the grid side is economically rational because each power provider does not have to install its own storage batteries and the number of storage batteries in a single grid can be reduced. Moreover, since power providers do not have to reduce output variations, they have a large advantage in that the load of operation management will be reduced.

Since the scale of the grids in Hokkaido is primarily smaller than that of power companies in other areas, expansion of the amount of renewable energy raised the problem of limited control capability before. Thus, HEPCO Network have phased in an interconnectable capacity for renewable energy. This introduction of grid storage batteries is an effective solution to the issue. Ryosuke Nakamoto, who was in charge of grid plans and engaged in the energy storage battery introduction project at HEPCO Network recounted the details.

“Hokkaido has enormous potential for renewable energy, such as wind power generation. HEPCO Network has made efforts to phase in the introduction of renewable energy. However, our control capacity was reaching the limit, so we requested wind farms to satisfy new requirements for output variation mitigation. In other words, we required each farm to install storage batteries to level output variations. While the number of wind farms has increased, however, a national committee submitted a report stating that central operation of storage batteries on the grid side is efficient. We solicited wind farms to participate in the large energy storage battery installation project on a cost-sharing basis and have determined to introduce the large energy storage batteries,” said Nakamoto.

Taking the initiative, HEPCO Network started a grid energy storage battery project in which wind farms jointly participated.

Construction during COVID-19 pandemic and frigid, inclement weather

Sumitomo Electric conducted a large-scale demonstration test of redox flow batteries with HEPCO at Minami-Hayakita Substation for three years from 2015. Since then, Shuji Hayashi, the manager of the 1st Energy Storage Engineering Group, Flow Battery System Engineering Dept., has been in charge of technical aspects.

“We have established stable and safe operations of grid storage batteries by trying to develop optimum control and operation techniques that mitigate the impact on the grid due to power fluctuations of renewable energy and maximize the efficiency and lifetime while evaluating the performance of redox flow batteries. In 2019, HEPCO decided to introduce and operate grid storage batteries and launched a solicitation process for procurement. We took part in the solicitation,” said Hayashi.

Although jointly conducting the demonstration, Sumitomo Electric did not have any advantage. The solicitation process was totally fair and transparent. Makoto Hashimoto, the manager of the Hokkaido Branch Office, looked back.

“The greatest problem was the cost of redox flow batteries. We understood the price disadvantage; however, we received favorable feedback on and gained their confidence in our technological prowess through communication with HEPCO. I felt a sense of great relief when hearing their decision. I also felt tense with a renewed awareness that we were just at the starting line of actual operations,” said Hashimoto.

Thus, the construction of the redox flow battery system was started in July 2020. After that, Hayashi managed the project as a project manager. He reduced time and costs by cutting waste in all processes. However, the COVID-19 pandemic blocked the project. Kazutoyo Mitani faced the construction work as a deputy at the site.

“The COVID-19 pandemic stopped port functions, prevented goods transportation, and limited the number of construction workers. The construction work was delayed from the beginning, and the deadline of March 2022 was approaching. I struggled with the construction, feeling anxiety. When winter came, it became frigid at the construction site. The construction work started in the early morning at a temperature of −25°C. We suffered from troubles, such as the highest accumulation of snow ever recorded and a rainstorm like a typhoon. We carried on the struggle to catch up on the construction progress,” said Mitani.

To increase the potential of renewable energy in Hokkaido

The construction work was almost completed in November 2021, and then tests were conducted until the time of handover. Shohei Fukumoto was charged with the tests. Fukumoto had studied storage batteries at university and mainly taken charge of overseas redox flow battery projects in Morocco, Taiwan, and Belgium since joining the Company. During the tests, problems related to the power conditioning system (PCS) occurred.

“The PCS is a device that converts direct current to alternative current so that the electricity can be used for home appliances. The role is to convert generated electricity to connect a power grid. The PCS is the most important device in a redox flow battery system. The problems caused unstable operations of the system. Since it was made by an overseas manufacturer, we asked them to come to Japan for adjustment, but they could not come due to the pandemic. I clearly remembered that we communicated with each other online to solve the problems,” said Fukumoto.

In combination with the efforts of Fukumoto and other members, the construction work was completed as planned on March 31, 2022. It seemed to Mitani a miracle that the construction was completed by the deadline. The project manager Hayashi said that he was moved to tears when the energy storage battery system was connected to the grid. “We made the most of the collective strength of Sumitomo Electric in this project,” said Hayashi. Thus, the redox flow battery facility was handed over to HEPCO Network. The aforementioned Nakamoto said in acknowledgment, “I felt the staying power of Sumitomo Electric when the project was completed as planned even during the COVID-19 pandemic.”

In this project, HEPCO Network installed grid storage batteries and (about 90% of) the incurred construction costs are shared with wind farms. HEPCO Network first commenced the solicitation process for wind power generation utilizing grid storage batteries (phase I). The solicitation approved 15 priority grid interconnection companies totaling 162 MW. Nakamoto talked about future development as follows.

“To gradually expand the interconnection amount of wind power generation while checking the impact on power grids, HEPCO Network launched the solicitation process in two phases. The solicitation capacity of phase I is 600 MW, which is a capacity that can assure technical reliability. The remaining capacity is 438 MW, and an additional solicitation process is underway. We will introduce more storage batteries to exploit the maximum potential of renewable energy in Hokkaido,” said Nakamoto.

Sumitomo Electric has already started taking on the challenge of establishing the presence of redox flow batteries in Hokkaido.

Facility for the large-scale demonstration test of redox flow batteries together with HEPCO in 2015

NEXT

Using Microgrids to Generate Power for the Wholesale Market

– A Demonstration of VRF Technology with NEDO in California, USA –

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.