Uncovering new value by continuously asking “Why?”

For engineers and researchers, the pursuit of knowledge through original research—asking why something happens and pursuing the answer wherever it takes them—can yield benefits that ripple throughout the company and for customers. In the case of Shoshi Katakai, it meant remaining committed to solving the mystery of why the world’s highest alternating current (AC) voltage cross-linked polyethylene (XLPE) cable failed after seven years of operation. In the face of skepticism, Katakai was able to reproduce the failure in the lab after six months of trial and error. The practice of answering the “why” question resulted in important improvements in the quality of existing products—and helped fuel the creation of a revolutionary new technology.

Shoshi KATAKAI

Ph.D.

Fellow

Power Cable Division

Specialized in development and research of insulating materials and EHV cables.

Most distinguished achievement: Development of a new polymeric insulating material for DC power cables.

Making a long-anticipated technology a reality

While the cable whose failure Katakai had previously examined carried AC, there was also strong interest in direct current (DC) transmission. Each type of current has its advantages, and while AC has been widely adopted due to the ease of reducing voltage levels for home use, DC has advantages such as efficient long-distance transmission.

In 1979, the first DC power cable used in Japan for long-distance transmission was an oil-filled (OF) insulated cable, an insulation technology that had a long track record of successful use with AC. The industry began adopting cables insulated with a polymer called XLPE, which provided excellent performance for AC transmission. However, using XLPE cable “as is” for DC did not bring out the full potential for the cable’s performance. Ultimately, this material did not become the standard for DC, despite many advantages such as eliminating the risk of environmental damage caused by oil leaks under water and a reduced need for maintenance. The widespread adoption of DC XLPE cables had been an unrealized dream of cable engineers, academics, and materials researchers.

In 1985, Katakai began his trial-and-error research to seek the truth about why XLPE was not the ideal insulator for DC transmission that it should have been. Specifically, XLPE had low DC breakdown strength. He investigated a number of facets of the issue: identifying and describing the root cause, searching for new materials, establishing an evaluation method, developing quality thick and extra-long cables, to name just a few.

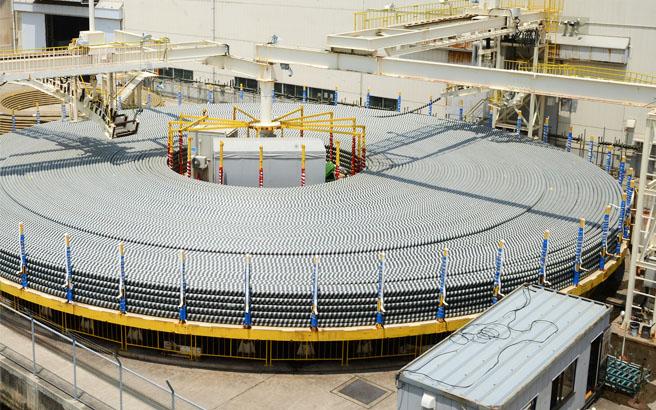

Thanks to some 25 years of persistence and dedication, Katakai successfully developed a viable DC XLPE cable—one that could carry large loads over long distances with all the benefits of the solid XLPE technology over oil-filled cables. In 2012, Sumitomo Electric laid the new DC XLPE cable between Hokkaido and the mainland of Japan, putting it into operation for the first time. It’s also in use as a key transmission line in Europe, connecting the UK to Belgium.

Success requires being open to new possibilities

A major element of Katakai’s success came in the examination of two insulating materials with very different characteristics: pure polyethylene and filled polyethylene. When Katakai began his work, he believed that pure polyethylene had the greatest potential and it performed well in his experiments. But as he increased its thickness to a level appropriate for use in a transmission cable, its performance faltered. On the other hand, filled polyethylene, which seemed less promising, was ultimately selected because the filler that is mixed into polyethylene helps improve DC insulating performance, no matter how thick the cable was.

The lesson was clear: never rule out any possibilities. For Katakai, seeking the truth also meant pursuing solutions without preconceptions. The path to success can push you beyond initial assumptions.

“I specialize in electrical engineering, but the truth I seek may not always be found in the field of electric engineering,” says Katakai. “If chemistry is necessary, I will learn the necessary knowledge of chemicals. If analysis technology is required, I will study applied physics. If I need a new material, I will visit various materials manufacturers. To seek the truth, I organize a team of experts in various fields and investigate from a wide range of perspectives and many different angles.”

This openness led to new perspectives, collaboration with talented colleagues across industry and academia, and unexpected discoveries. Together, they were the driving force behind the development of the DC XLPE cable. And, ultimately, all of these accomplishments are evidence of the real-world benefits of a simple goal: seek the truth.