Ceramic Technology Enables Cutting Edge Energy Science

MRI has helped millions of patients around the world as a diagnostic tool able to create images of soft tissue like the heart and brain and to identify tumors. But the technology would not be possible without superconductors. Superconductors are metals and other compounds that, when subjected to extremely low temperatures, can conduct electric currents without losing energy (what we call zero resistance) and produce strong magnetic fields.

The concept of zero electric resistance is understandably appealing when developing energy infrastructure, and the Japanese government is promoting further development of this technology. It’s believed that the transmission loss of electric power is 5%, so reducing or eliminating that loss represents huge energy savings with major financial and environmental benefits.

But deploying superconductor technology, whether in an MRI machine or to transmit power in the outside world, requires overcoming major practical challenges. The phenomenon of superconductivity was discovered in 1911 when mercury displayed zero resistance when cooled below what’s called its critical temperature. In order to use superconductors at that time, a cooling system that generated a temperature of 4 kelvin was required, which was expensive and an obstacle to the practical application of superconductivity.

In the decades that followed this discovery, researchers tested a variety of materials with the aim of identifying superconductors with higher critical temperatures, but it wasn’t until the late 1980s that scientists began to discover “high-temperature superconductors” that work at comparatively warmer 77 kelvin (-196℃) and higher. While these are still very cold temperatures, superconductivity in this range also becomes more financially feasible because it means we can use liquid nitrogen (with its boiling point of -196℃) which is inexpensive, especially when compared to the liquid helium (boiling point -269℃) required for earlier superconductors.

From such background, Sumitomo Electric has been focused on finding superconducting materials with higher critical temperature and developing practical products from such superconductors. Over the years, we have achieved considerable success in these areas while continuing to push for new discoveries and innovations.

Applying our wire manufacturing expertise to a new challenge

Sumitomo Electric traces its origins back to 1897, when it was known as the Sumitomo Copper Rolling Works and pioneered the domestic manufacture of electric wire and cable in Japan. For 125 years, we have been committed to improving transmission technology, and in 1966 we began researching the possibility of using superconductor technology to create zero electrical resistance wires.

When the discovery of a bismuth-based superconducting compound was reported in 1988, it spurred a global wave of research into practical applications of the material. Sumitomo Electric focused on the bismuth-based superconductor and took on the challenge of developing its practical use wire, achieving success within just a few years.

The key to the success of the newly developed wire is the special pressurized sintering process. In this process, sintering superconducting materials with very high pressure to eliminate the void for increasing density can achieve higher critical current and stronger mechanical strength of the practical use wire.

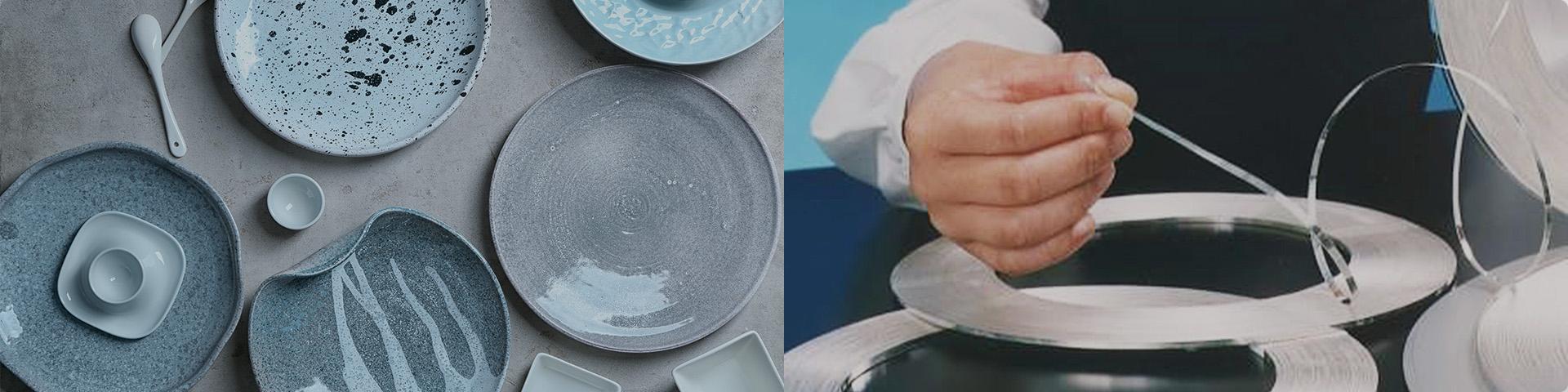

Ceramics manufacturing technology creates reliable superconductors. The bismuth-based compound that Sumitomo Electric uses is a kind of ceramic material, using the same method as other ceramics. Newly developed wires could be cooled by liquid nitrogen, immediately lowering its application cost compared to conventional superconducting materials that needed liquid helium. So, we are currently working on the mass production of these superconducting wires.

Sumitomo Electric has completed various verifications as one of the world’s top manufacturers of bismuth-based superconducting wire, and we have built a long record of achievements. Our bismuth compound is considered the first generation of high-temperature superconductor materials, one that has proven reliable and stood the test of time. Some in the industry have adopted next-generation yttrium-based superconducting materials, but bismuth-based superconductors do not use rare earth elements such as yttrium, so we can provide our customers with superconductors while maintaining environmental sustainability.

Superconductivity will continue to benefit society

As superconducting technology progresses, it will enable advances in many parts of life. In healthcare, if stronger magnetic fields become a reality, that would create the potential for smaller MRI machines or increased sensitivity to detect medical issues sooner. For electric power transmission, the use of superconductors may enable significant energy-saving.

Sumitomo Electric remains committed to developing technology that will yield superconductivity at higher temperatures, making opportunities like these, and so much more, possible.