Soft Magnetic Composite Products Create a Sustainable Future

Product line of soft magnetic composites products

Taking on the challenge of creating a market for axial flux motors

A Specialized Sales Group Aiming to Drive Increased Adoption

As the development of soft magnetic composites intended for incorporation into axial flux motors progressed, a specialized group was formed. This group was established as the New Business Sales Group. Daichi Azuma, who has long been involved in materials research and development, has taken on a role in charge of soft magnetic composites. The reason for his transfer to the sales department was that indepth knowledge was essential to encourage the use of soft magnetic composites.

“This position is best described as technology development sales. I serve as a liaison between the research department and our customers and am currently working to enhance the recognition of soft magnetic composites. Soft magnetic composites have potential for adoption in various industries where motors are used and where there is a need to reduce size and weight, such as in home appliances, industrial machinery, and automobiles.

We are promoting activities to generate interest and highlight the advantages of soft magnetic composites, including product promotions at exhibitions, and on our website, and through our internal network. Most of our customers are engineers in the design and development departments. We listen to each customer’s needs, present them to the development department, and then proceed with creating prototypes and making proposals.” (Azuma)

In the course of these activities, we learned that Daikin Industries, Ltd. (hereinafter referred to as Daikin), a global leader in air conditioning manufacturer, was preparing to develop an axial flux motor. As Azuma continued to communicate with Daikin’s designers, he sensed a positive response to the adoption of soft magnetic composites. The person who took over the helm from Azuma was Midori Nakae.

Axial Flux Motors Installed in Home Air Purifiers

“The entire sintering department came together, determined to ensure that the product would be adopted. We were already doing business with Daikin for sintered products, including bearings, and had contact with their procurement department. However, as this was a new initiative, we asked a member of the design department to join us in the meetings. We also organized a technical exchange session for the engineers from Daikin, which included discussion on soft magnetic composites. Daikin was proactive about developing the axial flux motor, and I believe the engineers were able to understand each other and reach an agreement quite smoothly.” (Nakae)

Unlike the automotive industry, where the adoption of soft magnetic composites can take more than a couple of years, an extremely tight schedule of just one year from development to mass production was required. To achieve this, close cooperation between the manufacturing and development departments was necessary.

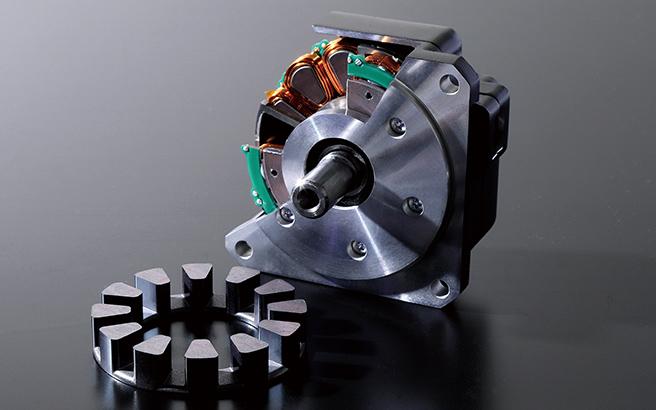

There was also a possibility that electromagnetic steel sheets, used in previous models, would be adopted. Nakae emphasized the superiority of soft magnetic composites, namely their freedom in terms of shape. A further challenge arose, which was the need for a soft magnetic composite with a flange shape on both end faces, a feature patented by Sumitomo Electric Industries. This soft magnetic composite would make it possible to make the device thinner while maintaining its performance. However, since it had no track record of mass production, research into how to make it a reality was conducted at a rapid pace. In this way, the company was able to quickly receive an order in January 2023 and start mass production in May of the same year. Nakae said she felt a great sense of relief.

Mr. Yoshinori Takayama, a Daikin representative, said the following:

“When we started developing the axial flux motor, we intended to incorporate new technological elements. During this process, we came across Sumitomo Electric’s soft magnetic composites, which offer high design flexibility and are well-suited for small-scale production.

One of the key features is the incorporation of a flange shape on both ends. This allows us to shorten the average winding circumference while maintaining the area facing the magnet, thereby achieving a thinner motor and improved efficiency.

We hope that Sumitomo Electric will continue to propose one-of-a-kind products in the future. Additionally, to further expand the use of soft magnetic composites for motors, we would like to see them challenge themselves in developing both cost-effective materials and manufacturing processes.” (Mr. Takayama)

Soft Magnetic Composites Catering to Robust Demand for Motors

The mass production of soft magnetic composites for axial flux motors represents a pioneering effort not only domestically but also internationally.

“At our company, the history of soft magnetic composites spans a quarter century, during which time they have consistently evolved in terms of efficiency and energy conservation. My mission is to promote the transition from magnetic steel sheets to soft magnetic composites in the design and development of motors. Axial flux motors are ideally suited to leverage the properties of soft magnetic composites, and they represent a very large market. Our goal is to identify the challenges that hinder our customers’ design and development processes, and create new markets for soft magnetic composites.” (Azuma)

The sales department of the Sintered Metal Components Division is led by General Manager Hiroyuki Shibai. Shibai is responsible for overseeing the sales of all sintered metal components manufactured by the Sumitomo Electric Group, and has great expectations for soft magnetic composites.

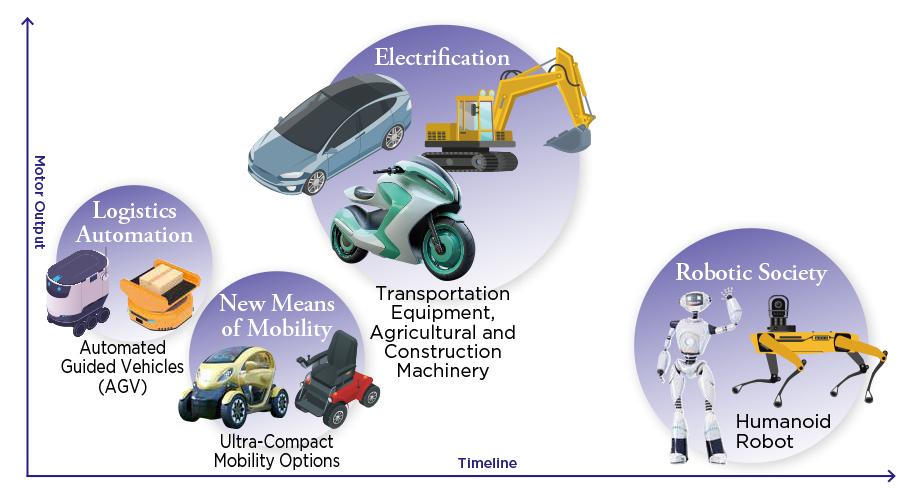

“Initially, the markets we will approach will include industries such as industrial equipment, home appliances, and automobiles. In particular, as the electrification of automobiles is accelerating, we believe there is significant demand for compact and lightweight axial flux motors.

Furthermore, humanoid robots are gaining popularity. Humanoid robots equipped with advanced technologies like generative AI are now being developed one after another in Japan and overseas. The era when robots will take over various kinds of labor is not far off.

Movements such as walking, as well as motions of the arms, elbows, fingers, feet, etc. are all controlled by motors, and ultra-small motors are required for the joints of the fingers. I believe soft magnetic composites we have been pioneering will demonstrate their potential, creating a great business opportunity.” (Shibai)

Sumitomo Electric’s soft magnetic composites, which have a history of a quarter century, have entered a new phase. The widespread use of soft magnetic composites will surely change the world of motor development. The time is not too far off when compact, lightweight, high-output, and recyclable energy-saving technologies will play a part in supporting a sustainable society.

Awarded the Grand Prix at the 46th JPMA Awards in 2024

Sumitomo Electric won the 46th Japan Powder Metallurgy Association (JPMA) Grand Prix in 2024 for its development of integrated double-flange soft magnetic composites that contribute to improving the performance of axial flux motors.

In this development, the soft magnetic composite was designed with overhanging flanges on both the top and bottom sides of the section where the copper wire is wound. The integrated double-flange soft magnetic composite was found to demonstrate high dimensional precision along its entire length and to have superior quality compared to magnetic steel cores.

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.