Opening Up a New World of Soft Magnetic Composites

Axial flux motor and soft magnetic composite (in the foreground)

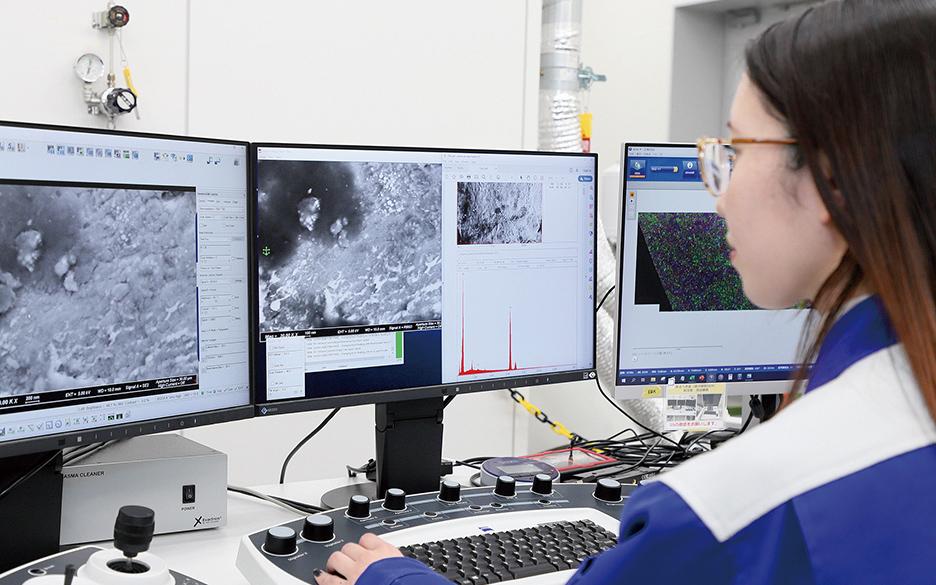

Development of soft magnetic composites for axial flux motors

High Performance and Lightweight Disk Structure

Since around 2005, the Sumitomo Electric Group has been conducting research and development of soft magnetic composites for axial flux motors. Tomoyuki Ueno has continued to be involved in the research and development since that time. He has been involved with soft magnetic composites since his days at the Advanced Materials Laboratory. In 2023, he took up the post of General Manager of the Electric Module Development Department at Sumitomo Electric Sintered Alloy, Ltd., which was newly established with the aim of expanding the use of soft magnetic composites in axial flux motors.

“In 2005, when motors were installed in hybrid vehicles, we started to look into the possibilities for axial flux motors. The soft magnetic composites available at the time had poor insulation performance, heat resistance, and strength, and did not meet the required performance. Then, around 2014, against the backdrop of environmental concerns, including improving fuel efficiency and combating global warming, the market once again demanded smaller, lighter motors.

We believed that soft magnetic composites would have an advantage over magnetic steel sheets in terms of compactness and light weight, so we restarted our research and development. We repeatedly constructed prototypes and accumulated knowledge.

The motor market is huge, providing significant business opportunities, and we believe that the widespread use of axial flux motors equipped with soft magnetic composites, which are highly energy-efficient, will contribute to a sustainable society, which is why we have accelerated our research and development.” (Ueno)

The soft magnetic composite developed by Ueno and his team changed the basic structure of the motor from cylindrical to disk form, achieving a lighter and thinner design. Compared to conventional radial flux motors, it has achieved a reduction in weight and thickness while maintaining performance equivalent to that of conventional radial flux motors in terms of torque and maximum efficiency.

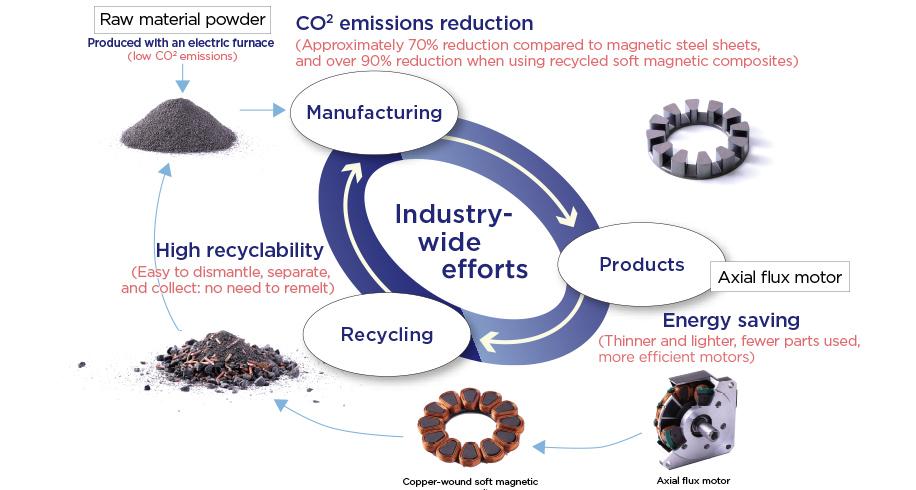

Significantly Reducing CO² Emissions and Recyclable

The soft magnetic composites were first used in axial flux motors for industrial machinery in 2020. Tatsuya Saito, who works in the same Electric Module Development Department as Ueno, has been involved with the soft magnetic composites since joining the company and has proactively approached customers to encourage them to adopt soft magnetic composites for axial flux motors.

“I accompanied the sales representative and highlighted the advantages of soft magnetic composites to a customer. The magnetic core determines the performance of a motor. The soft magnetic composite has properties not found in electromagnetic steel sheets, such as being compact, enabling high torque, low energy loss, and the ability to form three-dimensional shapes. I stressed these properties to the customer.

We then created further prototypes and made repeated design changes to meet the customer’s needs. Furthermore, soft magnetic composites also have advantages from a sustainability perspective. Because the raw material is a powder, it can be crushed and recycled.

Furthermore, CO2 emissions can be reduced by approximately 70% when using new powder for soft magnetic composites compared to magnetic steel sheets, and by more than 90% when using recycled soft magnetic composites. The customer recognized the value of these diverse properties and decided to adopt the product. I felt that we had taken a solid step forward.” (Saito)

It was Masaaki Eida who considered manufacturing and mass-producing soft magnetic composites for customers. He has been involved with soft magnetic composites since the startup.

“The timeframe for starting mass production was tight, making close collaboration crucial. Based on preliminary shape proposals from the research department, we studied the costs and quality that would be viable for mass production, designed molds, and created prototypes. We cycled through this process quickly.

We particularly focused on improving the molding accuracy. Through repeated discussions within our team, we succeeded in achieving high precision by ensuring uniform filling of the magnetic powder in the molding process using a molding press. Not only did we respond to the customer's request, but we also proposed our own pioneering technology and brought it to mass production. This achievement brought us great joy.” (Eida)

Demand for High Motor Efficiency and Energy Saving

Motors have long been recognized as a challenge due to their energy consumption, which is said to account for nearly half of the world's electricity consumption. By improving the efficiency and energy-saving features of motors, this reduction in power consumption leads to a decrease in CO2 emissions, contributing to the mitigation of global warming.

“We believe that soft magnetic composites, which help achieve a small size, light weight, and high output, offer a major advantage in creating more efficient motors. Furthermore, going forward, we will need to provide added value. Establishing recycling technology is one aspect of this. In addition to simply supplying magnetic cores, we also want to gain a deep understanding of the motors themselves, so that we can identify issues before our customers do and enhance our proposals for axial flux motors. We are committed to remaining at the forefront and providing new value to the world.” (Ueno)

NEXT

Soft Magnetic Composite Products Create a Sustainable Future

- Taking on the challenge of creating a market for axial flux motors -

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.