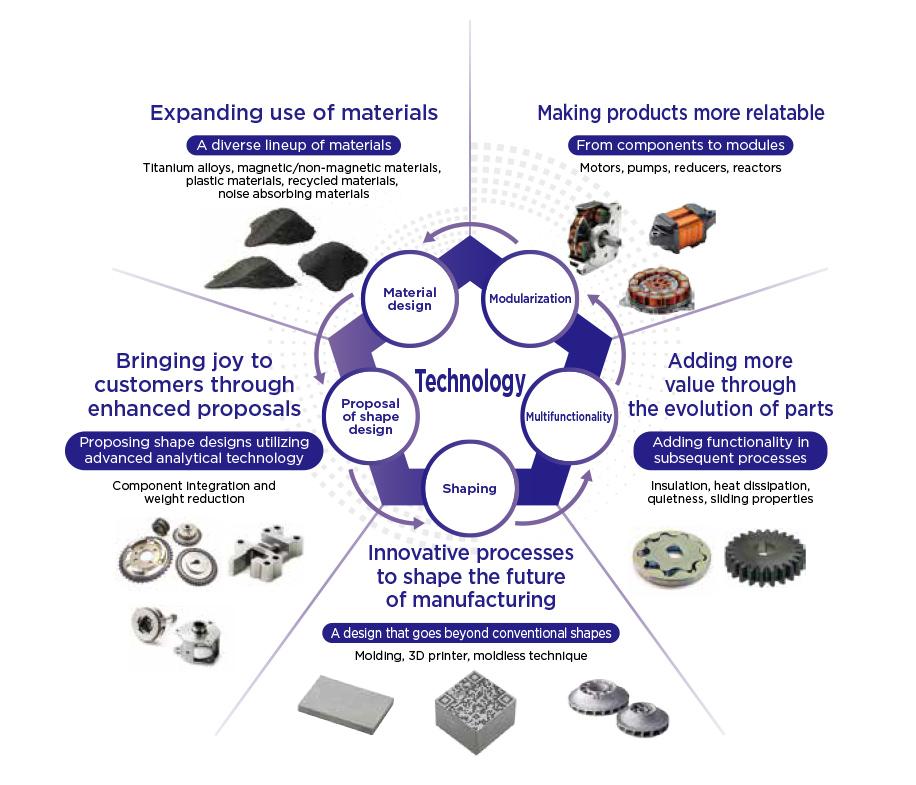

Soft Magnetic Composites Enabling Flexible Shapes, Compact Design, and Weight Reduction

Exceptional characteristics open up new markets

Sumitomo Electric’s Sintered Metal Components Boasting Over Half a Century of History and the World’s Second Largest Share

The sintered metal components handled by the Sintered Metal Components Division of the Sumitomo Electric Group are manufactured by placing powdered iron, copper, or other materials into a mold, compacting it with a pressure of approximately 3 to 10 t/cm2, and bonding the powder together at temperatures below the melting point (approximately 1,100 to 1,300°C) to form a solid product. Compared to forging and casting, this method has many advantages, including higher productivity, lower energy consumption, and the ability to form complex shapes. Currently, sintered metal components are primarily used in automotive components. The division's sintered metal components are used in engine oil pumps, variable valves, transmissions, and various components that make up automobiles.

The manufacture and sale of these sintered metal components began in 1948 at the Itami Works of Sumitomo Electric Industries, Ltd. Okayama Sumiden Seimitsu Ltd. was founded in 1972 with two manufacturing sites: the Head Office/Okayama Plant and the Itami Plant. Afterward, as Japanese automobile manufacturers expanded their overseas production, the company expanded its business by establishing production sites in the United States, Mexico, China, Thailand, Malaysia, Indonesia, and other countries. Currently, the company holds the top market share in sintered metal components in Japan and the second largest market share in the world.

Soft Magnetic Composites Made by Insulating Each Individual Grain of Magnetic Powder

This issue focuses on soft magnetic composites, which are components formed by molding soft magnetic iron powder into a three-dimensional shape using a molding press. The company's efforts in soft magnetic composites began in the early 2000s, as it focused on properties not present in conventional sintered metal components.

These soft magnetic composites use iron powder coated with an insulating film. This insulation coating is one of the key characteristics of these composites.

Conventional magnetic cores, made of laminated electrical steel sheets, can provide insulation only between the layers. In a soft magnetic composite, each particle of powder is coated with an insulating film, allowing the core to achieve both high electrical resistance and high magnetic force. This will enable units equipped with soft magnetic composites to achieve high power, smaller size, and reduced energy loss.

The first product to adopt soft magnetic composites with these outstanding characteristics was introduced to the market in 2003. Specifically, this product was the common rail fuel injection valve for clean diesel engines. Due to the soft magnetic composite, the product contributed to improved fuel efficiency. In addition, the ignition performance of the gasoline engine’s ignition coil was improved, resulting in enhanced fuel efficiency. Mass production of reactors began in 2012, and in 2020, the product expanded to include axial flux motors.

Developing New Markets Under the Theme of “Drive”

The person in charge of steering the sintered metal components business, including soft magnetic composites, was Hideo Kobayashi, who was then in the Sintered Metal Components Division’s Strategic Planning Department, which was newly formed in July 2023. Kobayashi became General Manager of the department in October that year. The new department was formed due to major changes occurring in the automotive industry.

“More than 90% of our sintered products department’s customers are in the automotive industry, which is facing a once-in-a-century period of great change with the emergence of the concept of ‘Connected, Autonomous, Smart/Shared & Services, Electric’ (CASE). This department was established to develop and implement future strategies and plans. In the sintered products department as a whole, about three-quarters of production is done overseas, so we need to optimize our manufacturing sites, including supplementing production, from a global perspective. An even bigger challenge is the demand for automobiles in the near future. On the one hand, the popularity of EVs will grow; on the other hand, the demand for gasoline-powered vehicles will continue to decline. In this context, we are considering supplying sintered metal components, including soft magnetic composites, to markets other than the automotive industry. As a component necessary for drive, we intend to approach new markets, including new mobility (next-generation transportation means and services).” (Kobayashi)

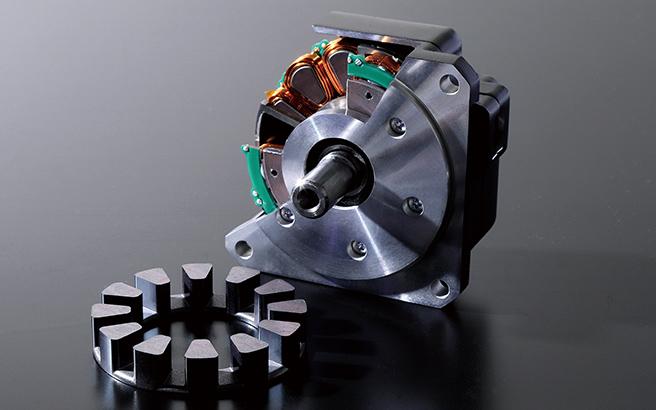

Milestone: Use in Axial Flux Motors

Most of the moving components in a car are equipped with a motor. It is a device that uses magnets to convert electrical energy into motive energy. When an electric current flows, a magnetic field is generated, and the poles attract and repel each other, creating rotation. A magnetic field is generated by coiling copper wire. The magnetic field is made stronger by wrapping the wire around a magnetic core, which helps maximize efficiency and power output.

Until now, most motors have had a radial flux structure, and the material for the magnetic core has largely been electromagnetic steel sheets. In recent years, axial flux motors have been attracting attention as small, highpower motors in fields such as automobiles and industrial robots.

“Our company has developed and supplied products that use soft magnetic composites, such as fuel injection valves, ignition coils, and reactors. A major feature of these products is that the material itself is functional, which makes these products one of the pillars of our business. Furthermore, the adoption of soft magnetic composites in axial flux motors, a pioneering technology in the industry, marks a major milestone for soft magnetic composites, and the marketing of these composites will become extremely important in the future. What markets will we serve? This will lead to the creation of new business models. We need to find new demand and applications, not just in the automotive sector, and link them to sales by highlighting the advantages of soft magnetic composites. I believe we are at a critical juncture.” (Kobayashi)

NEXT

Commitment of All Employees at Sumitomo Electric Focused on the Production of Proprietary Soft Magnetic Composites

- Reactors designed to be compact, lightweight, and optimized for efficient production -

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.