Commitment of All Employees at Sumitomo Electric Focused on the Production of Proprietary Soft Magnetic Composites

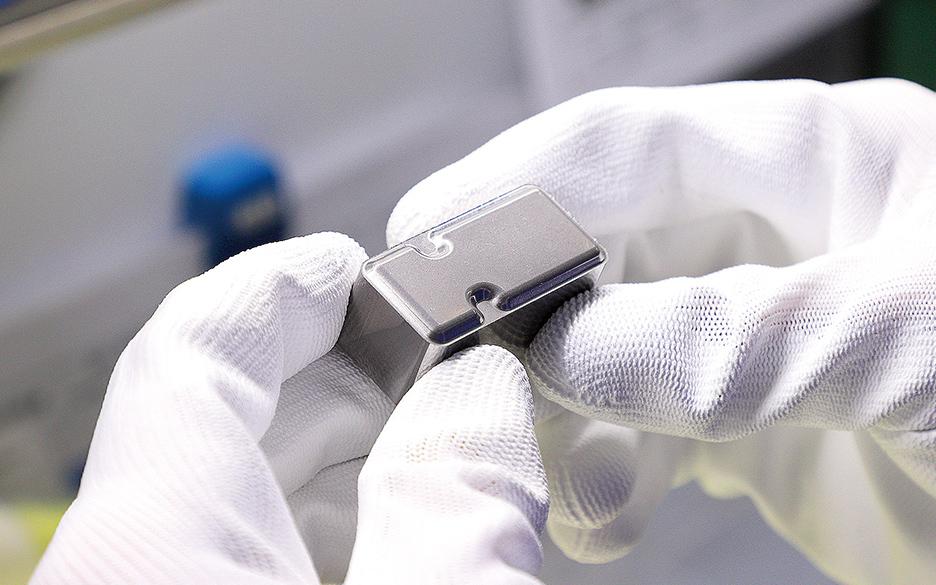

Soft magnetic composite after heat treatment

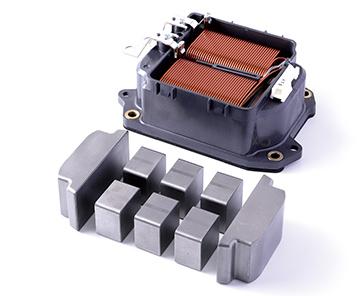

Reactors designed to be compact, lightweight, and optimized for efficient production

Advanced Technology in the Manufacturing Process of Soft Magnetic Composites

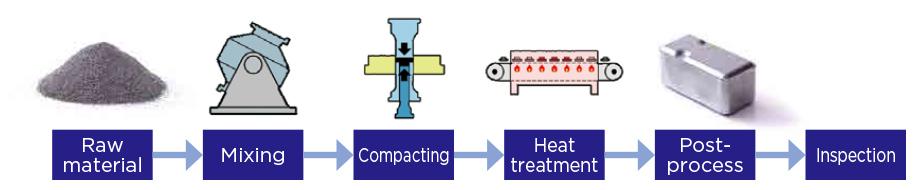

Let’s take a look at the manufacturing process of soft magnetic composites. First, additives are mixed into magnetic powder coated with an insulating layer, and the mixture is press-molded. After that, unlike sintering, which bonds the powder grains together, heat treatment is carried out at low temperatures of about 400 to 800°C to release the strain caused by molding. The lowtemperature heat treatment saves energy, and the powder particles do not bond together, making the product highly recyclable. Compared to magnetic cores made of laminated electromagnetic steel sheets, the soft magnetic composites formed in this way have high magnetic flux density (a quantity that indicates the strength of magnetic force), freedom in terms of shape, and excellent high-frequency characteristics. They also contribute to reducing the environmental impact by enabling products to be more compact, lighter, and have higher output.

Reactors that Boost and Smooth Voltage

In recent years, the electrification of vehicles has progressed rapidly due to environmental concerns and a desire to save energy. There is a need for the entire system to be more efficient and more compact and lightweight in order to further improve fuel efficiency. Meanwhile, higher voltage is also required to achieve driving performance on par with that of gasoline-powered vehicles. One of the techniques for achieving this is to use a boost converter, the key component of which is the reactor. The device boosts and smooths the battery voltage to supply a stable voltage. By providing the optimal voltage boost according to the driving conditions, it plays a role in improving the performance of the motor and the efficiency of the entire power control unit. In response to this need, the Sumitomo Electric Group has brought to the market a reactor that uses soft magnetic composites.

Maintaining Inductance at the Required Level

It was back in 2012 that the Sumitomo Electric Group began mass production of reactors using soft magnetic composites. Since then, there has always been demand for smaller and lighter devices. To meet this demand, the new focus it tackled was on improving inductance, a measure of performance. It is an indicator of magnetic energy storage; the higher this value, the more energy can be stored. However, depending on the driving conditions, inductance may decrease. To achieve a smaller reactor while maintaining inductance within the required range under various driving conditions, it was necessary to increase the saturation magnetic flux density of the soft magnetic composite.

The saturation magnetic flux density is the maximum magnetic force that a magnetic material can handle; the higher the saturation magnetic flux density, the more compact the magnetic core can be made.

To achieve this, pure iron powder, which has a high saturation magnetic flux density, was used, and a three-dimensional shape utilizing the characteristics of the soft magnetic composite made it possible to further reduce the size. In addition, improvements in heat dissipation and a lighter plastic case have achieved a 10% reduction in size and weight compared to previous models.

This research and development initiative is being carried out through the collaborative efforts of the Sumitomo Electric Group. Sumitomo Electric's Automotive Business Unit is responsible for customer negotiations. Design and development efforts by AutoNetworks Technologies, Ltd. respond to these customer needs. The reactor windings (copper wire) are made by Sumitomo Electric Wintec, Inc.; the soft magnetic composites are produced by Sumitomo Electric Sintered Alloy, Ltd.; and the assembly is undertaken by Sumitomo Wiring Systems, Ltd. The manufacturing base for these soft magnetic composites is located at the Itami Plant of Sumitomo Electric Sintered Alloy, Ltd.

Reiko Okuno, currently the Assistant Manager of the Development Group in the Itami Manufacturing Department, has worked in product design for sintered metal components and plant production technology before taking on a role in the development and production of soft magnetic composites.

“I joined in 2018 when the second phase of mass production of reactors began. I have been involved with sintered metal components since joining the company, and in 2018 I was put in charge of magnetic materials for the first time and learned about them from scratch.

Soft magnetic composites are made by pressing iron powder with an insulating coating into a mold. However, friction when removing the core from the mold could damage the insulating layer, causing electrical conduction between adjacent iron powder particles and increasing iron loss.*

The excellent performance of the soft magnetic composite is achieved by insulating each individual grain of iron powder. Therefore, we began looking into how to prevent damaging to the insulating layer during the press molding process.” (Okuno)

* Iron loss: The loss of power as heat in the iron core of devices such as transformers and electric motors.

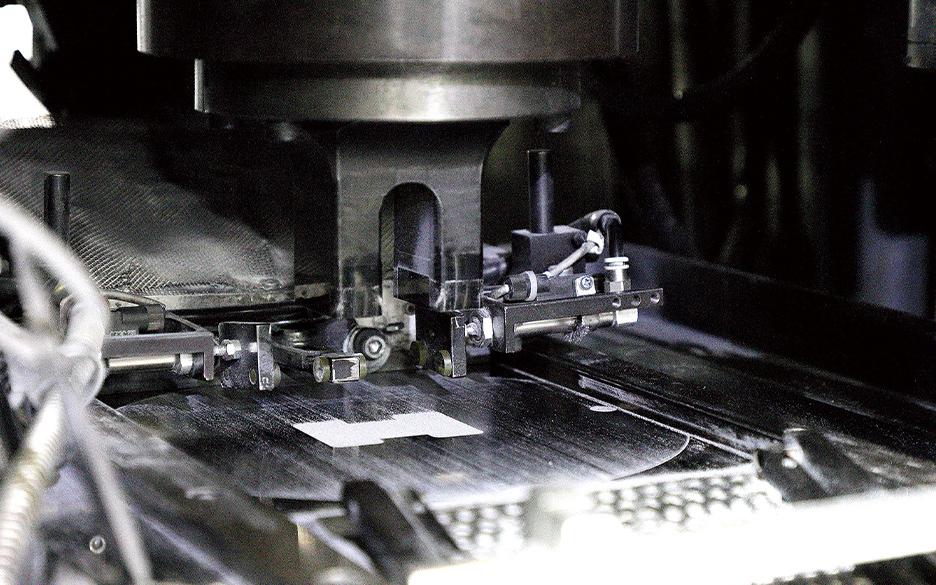

Application of the Revolutionary Manufacturing Technique Core Float

In the first phase of reactors, to prevent iron loss caused by damage to the insulation layer, laser processing was used to generate iron oxide, which blocked the flow of electricity. However, this process resulted in a significant increase in costs due to the additional process steps.

So for the second phase of reactors, the engineers came up with a revolutionary solution: using a floating mold to prevent damage to the insulation layer during removal. This improved the productivity and a patent was obtained. The performance expected of a reactor changes with the times, but the technology is not one that matures. What Okuno is currently focusing on is materials.

“How are customers using reactors? By accurately grasping this and realizing the performance that customers require, we aim to develop the materials themselves, including the composition of magnetic powder and insulation methods. By conducting magnetic analysis in parallel with our customers, we believe this will enable us to provide something extra with our solutions.” (Okuno)

Thorough Adherence to Quality Standards

Masanori Kubo, who was the General Manager of the Itami Manufacturing Department at that time, has been involved in the production of sintered metal components for many years. He has also been involved with soft magnetic composites from the beginning.

“As a plant operator, I always strive to meet quality standards. These are the conditions necessary to achieve the right results in the workplace, such as producing products of guaranteed quality.

In the production of soft magnetic composites, we consider both cost and productivity, such as the quality of raw materials, the movement and pressure of the mold, shape, dimensions, and surface finish, while strictly adhering to quality standards, which leads to providing the products that customers want. I expect that demand for reactors will rise as automobiles become more electrified. To that end, I see it as my responsibility to establish a stable mass production system.” (Kubo)

It can be said that the reactor, which the Sumitomo Electric Group is collaboratively working on, has established a significant presence in the world of soft magnetic composites. The insights gained through this development and production process will contribute to the development of soft magnetic composites used in axial flux motors.

NEXT

Opening Up a New World of Soft Magnetic Composites

- Development of soft magnetic composites for axial flux motors -

Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.