09 February 2021

Sumitomo Electric contracts with 50Hertz, an Elia Group company, to replace the 400kV Germany-Denmark Interconnector land cable on the German side. The new cable will be reliable & environmentally friendly and with innovative technology.

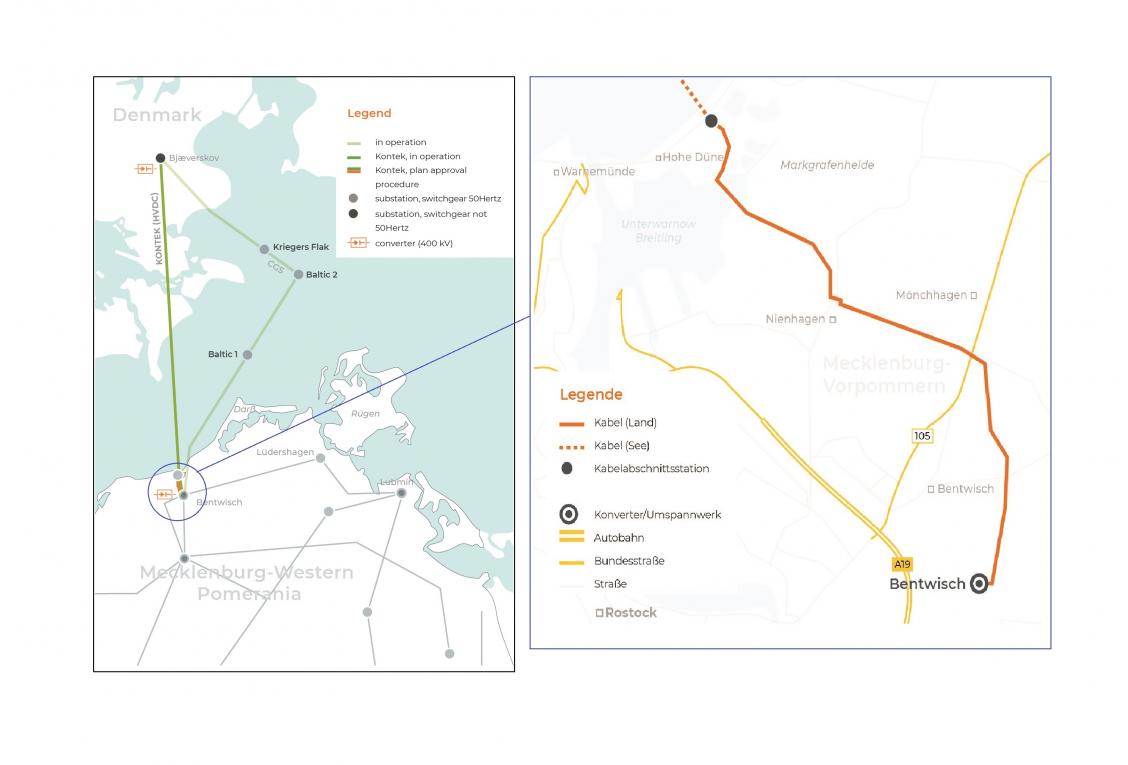

Sumitomo Electric Industries, Ltd. has been awarded a contract by German transmission system operator 50Hertz to replace part of the Germany-Denmark Interconnector (KONTEK). The contract covers design, procurement, production, transport, civil work, and installation of XLPE*1 insulated HVDC cable and ancillary components. It also covers more than 10 years maintenance service including emergency response to minimize the system unavailability.

Sumitomo Electric has developed and commercialized unique HVDC XLPE insulation technology that withstands the Polarity reversal*2 operation required for conventional LCC Converter System. “Sumitomo Electric’s XLPE cable is the perfect solution for the requirement of KONTEK to retrofit aged fluid-filled cable systems to more reliable and environmentally friendly technology. Considering the fact that a number of cable systems in the world with old technologies need to be replaced in coming years, we are confident that our XLPE solution will become a benchmark in the industry,” said Yasuyuki Shibata, Managing Executive Officer of Sumitomo Electric.

In 2019, Sumitomo Electric successfully commissioned the NEMO Interconnector for Elia Group and UK National Grid. As of today, NEMO is the highest voltage HVDC XLPE cable system in operation at 400kV. “With another 400kV KONTEK project for 50Hertz, along with 525kV Corridor A-Nord Project contracted in 2020 with another German TSO, Amprion, we reinforce our position as a technology leader in HVDC cable industry,” said Kazuhira Harada, Executive Officer. Sumitomo Electric recently opened its Power Cable Project office in Germany to enhance the company’s capability to support customers in Europe throughout construction, and maintenance phases.

*1 XLPE: crosslinked polyethylene. Conventionally, mass impregnated cables using highly viscous insulation oil have been utilized for HVDC projects. In recent years, XLPE insulated cables have been commonly adopted by the market due to their high allowable operating temperature and to growing environmental concerns. Sumitomo’s innovated HVDC XLPE technology allow cable system to operate at 90℃ with polarity reversal conditions and the world first commercial system has been operated since 2012 at Hokkaido-Honshu HVDC Link in Japan.

*2 Polarity reversal: interchange between positive and negative voltages (polarity) applied to a cable depending on the operating conditions of an interconnected DC power line.

For all media inquiries, please contact Public Relations Department, Sumitomo Electric Industries, Inc.

e-mail:web@info.sei.co.jp

Contact us

If you have any questions about the product, please contact us throught the following inquires form

Inquires Form