09 February 2026

Sumitomo Electric Launches Sales of Compact Membrane Treatment System Capable of Reducing Industrial Waste Disposal Volume by Up to 90% for Wastewater and Waste Liquids Containing Oil

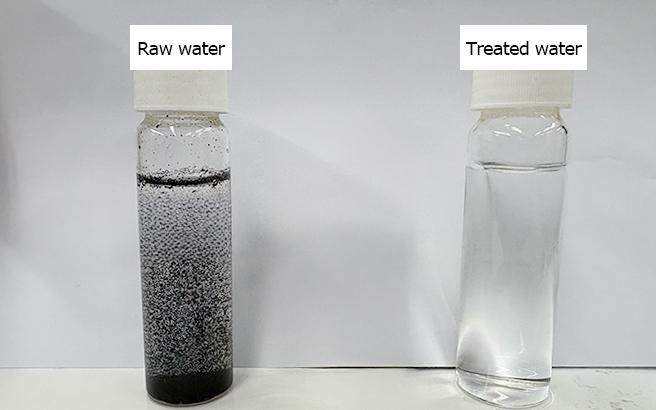

Sumitomo Electric Industries, Ltd. began sales in January 2026 of a compact membrane treatment system that enables the reuse of wastewater and waste liquids containing oil, such as waterjet cutting wastewater and coolant. This system can reduce industrial waste disposal volume by up to 90%*.

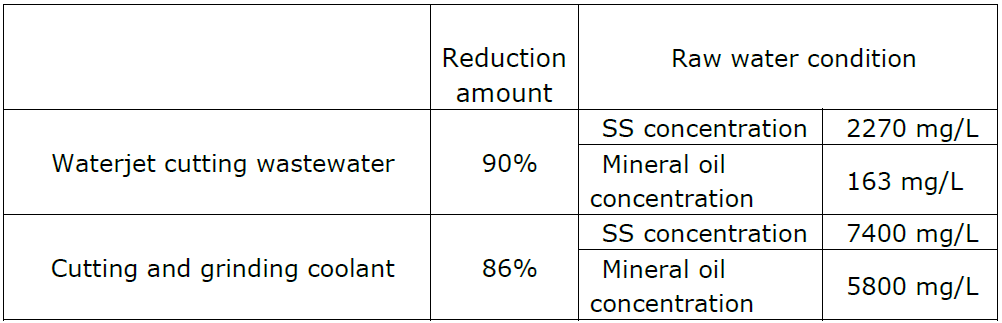

*Based on our company results. Raw water conditions: suspended solids (SS) concentration, 2270 mg/L; mineral oil concentration, 163 mg/L.

This system incorporates our proprietary polytetrafluoroethylene (PTFE)-based POREFLON™ membrane. Through precision filtration, it handles wastewater and waste liquids containing oil while achieving both high concentration and reuse of water and liquids. Its compact design reduces installation and power costs and facilitates operation across multiple sites. We continue conducting verification tests targeting waterjet cutting wastewater and cutting and grinding coolant, confirming excellent treatment performance: a 90% reduction for cutting wastewater and an 86% reduction for coolant.

This system has now been adopted by SHINTORA Holdings Co., Ltd. (Headquarters: Kita-ku, Osaka; President: Takashi Kimura) for treating wastewater generated during waterjet cutting of thick composite materials. SHINTORA Holdings prioritizes enhancing safety by reducing ignition risks during the removal of specialized equipment and minimizing environmental impact by reducing water usage. The system was selected in the recognition of its ability to treat wastewater containing oil, its capacity to achieve both water conservation and industrial waste reduction, and its compact, portable design for ease of use on-site.

We will continue to contribute to reducing our customers' wastewater and waste liquids volumes and work toward realizing a circular economy.

Features

· Achieves both high-precision filtration and increased concentration rates through precision filtration membranes.

· Contributes to reducing wastewater and waste liquids volumes and facilitating reuse.

Our Verification Results

· Sumitomo Electric's proprietary PTFE-based POREFLON™ membrane*1 handles oily wastewater and waste liquids.

· Compact design allows for portability, lowers installation and power costs, and facilitates operation at multiple sites.

*1: POREFLON™ membrane

A proprietary porous material from Sumitomo Electric made from 100% PTFE. A filtration membrane with excellent characteristics of POREFLON™

Applicable Examples

· Waterjet cutting water

· Cutting and grinding coolant

· Lubricating oil, degreasing liquid

· Separation of other special solutions

Equipment Specifications

· Processing flow rate: Up to 5 m³/d (depending on raw water quality)

· Membrane modules: 1 to 5 units

· Power supply: Single-phase 100 V

· Dimensions: 1800 mm x 800 mm x 1700 mm

Features of POREFLON™

Filtration precision: Removes solids 0.1 μm and larger.

Chemical resistance: Withstands chemical cleaning with a pH range of 0 to 14, including high-concentration alkalis.

Contamination resistance: Superior hydrophilic treatment prevents oil adhesion to the membrane surface and facilitates easy desorption, making it suitable for treating wastewater and waste liquids containing oil.

Durability: Made from a material resistant to tearing, vibration, and bending, ensuring long-lasting performance.

Permeability: High permeability due to high porosity enables excellent treatment capacity.

Sumitomo Electric POREFLON™ Website: https://global-sei.com/poreflon