Solution Case 02 Constituting Stable and Reliable Drainage Pump Systems

S-FREE™ Traveling Cables

Driving submersible axial-flow column pumps

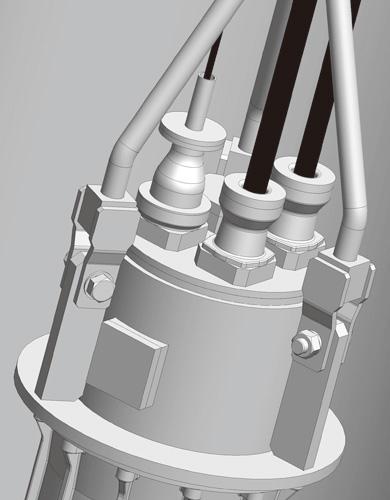

Tsurumi Manufacturing Co., Ltd. (hereinafter, Tsurumi Manufacturing), known for the brand “Tsurumi Pump,” is a traditional pump manufacturer established in 1924, which develops and manufactures various types of pumps for a broad range of applications, such as construction and civil works, agriculture and irrigation, river engineering and flood control, water supply and sewage systems, and environmental systems. In particular, in the category of submersible pumps, the company boasts a leading share of the Japanese market as a pioneer. Tsurumi Manufacturing has production bases in Kyoto and Yonago in Japan, as well as in China, Taiwan and Vietnam. In particular, the Kyoto Plant, which boasts the largest scale and the most advanced facilities in the pump industry, conducts every operation from development to production, accommodating diverse needs for pumps, from small to large sizes and special types. Tsurumi Manufacturing and the Sumitomo Electric Group have had a business relationship for about 40 years since the time when Hannan Electric Wire & Cable Co., Ltd., the predecessor company of Sumitomo Electric Industrial Wire & Cable Inc. was in operation, and traveling cables are part of products supplied by the Group to Tsurumi Manufacturing. Recently, Tsurumi Manufacturing adopted power supply cables for the driving motors of submersible pumps called “submersible axial-flow column pumps,” which are mainly used as sewage pumps to pump rainwater and wastewater, agricultural irrigation pumps, and high-volume lift/discharge pumps. The pumps boast the highest capacity in the category of submersible column pumps, being able to discharge a volume of water equivalent to a normal 25-meter swimming pool in only two minutes. We interviewed Mr. Ikuo Ishida, a unit leader in the Design Department of the Kyoto Plant, about the background to their decision to adopt Sumitomo Electric traveling cables for the pumps.

“Since before this project, we had had great confidence in Sumitomo Electric traveling cables. One of the important issues in this project was accommodation to special specifications designated by our client. The Sumitomo Electric Group accommodated special requirements regarding the diameters and lengths of cables appropriately and quickly. That was one of the reasons why we decided to use their cables. In addition, we were also very impressed with the cables’ properties. They are so flexible and easy to bend, as well as being light and easy to handle when performing cable terminal work. The packing of the cables is also very compact, allowing us to save on transportation costs,” says Mr. Ishida.

Highly accurate cable diameters ensure water sealing

One of the requirements of Tsurumi Manufacturing that the Sumitomo Electric Group accommodated is the arrangement of sealing for the penetrating section of cables. Perfect water sealing is one of the characteristics required for submersible pumps to prevent water from entering the pumps. Mr. Yasushi Miyagawa, the Deputy Manager of the Material Section, Procurement Department, Kyoto Plant highly evaluates the Sumitomo Electric Group’s adaptability.

“To arrange sealing, the accuracy of the cable diameters is very important. Although our requirements for water sealing were very strict, the Sumitomo Electric Group managed to meet them. In addition, the Group proposed a very innovative technology to stabilize cable diameters by using pressure produced by a cable material that the Group had specially arranged,” says Mr. Miyagawa.

Mr. Hideyuki Aikyo, a section manager in the Quality Assurance Department of the Kyoto Plant, expressed his own view of the Sumitomo Electric traveling cables, saying, “I don’t have any particular impression of the products.”

“For example, the products of the Sumitomo Electric Group are seldom a topic in our meetings on quality assurance because their quality is extremely stable. That proves their high reliability. Some time ago, during terminal wiring work, a cable was torn because a worker applied excessive force to it. In response, the Sumitomo Electric Group, not content with the existing product specifications, adjusted the properties of the sheathing rubber material to allow the cables to withstand potential excessive force and become easier for workers to handle, finally providing us with cables with higher tear resistance. This response shows the culture of the Group,” says Mr. Aikyo.

We asked the aforementioned Mr. Ishida what he expects from the Sumitomo Electric Group in the future.

“Submersible pumps are equipment that can make the most of the advantages of S-FREE™ cables, such as flexibility, bendability, durability, and ease of handling for cable terminal work, and therefore the products strongly supported the development of pumps that we aimed to create. I expect the Sumitomo Electric Group to evolve the features of S-FREE™ and develop even lighter and more cost-effective traveling cables,” says Mr. Ishida.

NEXT

Potential of S-FREE™ to Support Next-Generation Society —From Environmental Conservation to Data Centers

(6)Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form.

To delete your registration, please visit here.