15 January 2025

Development and Sales of Coated Carbide Grades AC9115T/AC9125T for Titanium Alloy Turning

Sumitomo Electric Industries, Ltd. (Head office: Chuo-ku, Osaka, President: Osamu Inoue, hereafter "our company") has developed and launched new coated carbide grades AC9115T/AC9125T, which can achieve long tool life in titanium alloy turning, for sale as of January 2025.

Titanium alloys are widely used in the aircraft industry due to their light weight, high strength and excellent corrosion resistance; their applications are also increasing in the medical industry due to its high biocompatibility. In recent years, these industries have been growing rapidly, leading to a yearly increase in the demand for tools able to machine titanium alloys.

Titanium alloy machining has long been subjected to short tool life due to adhesion caused by chemical reactions with the cutting tool, and wear during machining caused by low thermal conductivity. In response, our company has developed and launched new coated carbide grades AC9115T and AC9125T, which have excellent wear resistance and are optimal for turning titanium alloys.

1. Features

Utilizing our proprietary PVD* Absotech™ coating technology in AC9115T/AC9125T, as well as the industry's first tungsten carbide (WC) based composition that suppresses chemical reactions with titanium alloys and significantly increases wear resistance. This achieves long tool life in turning of titanium alloys, significantly contributing to improved productivity and reduced costs.

2. Lineup

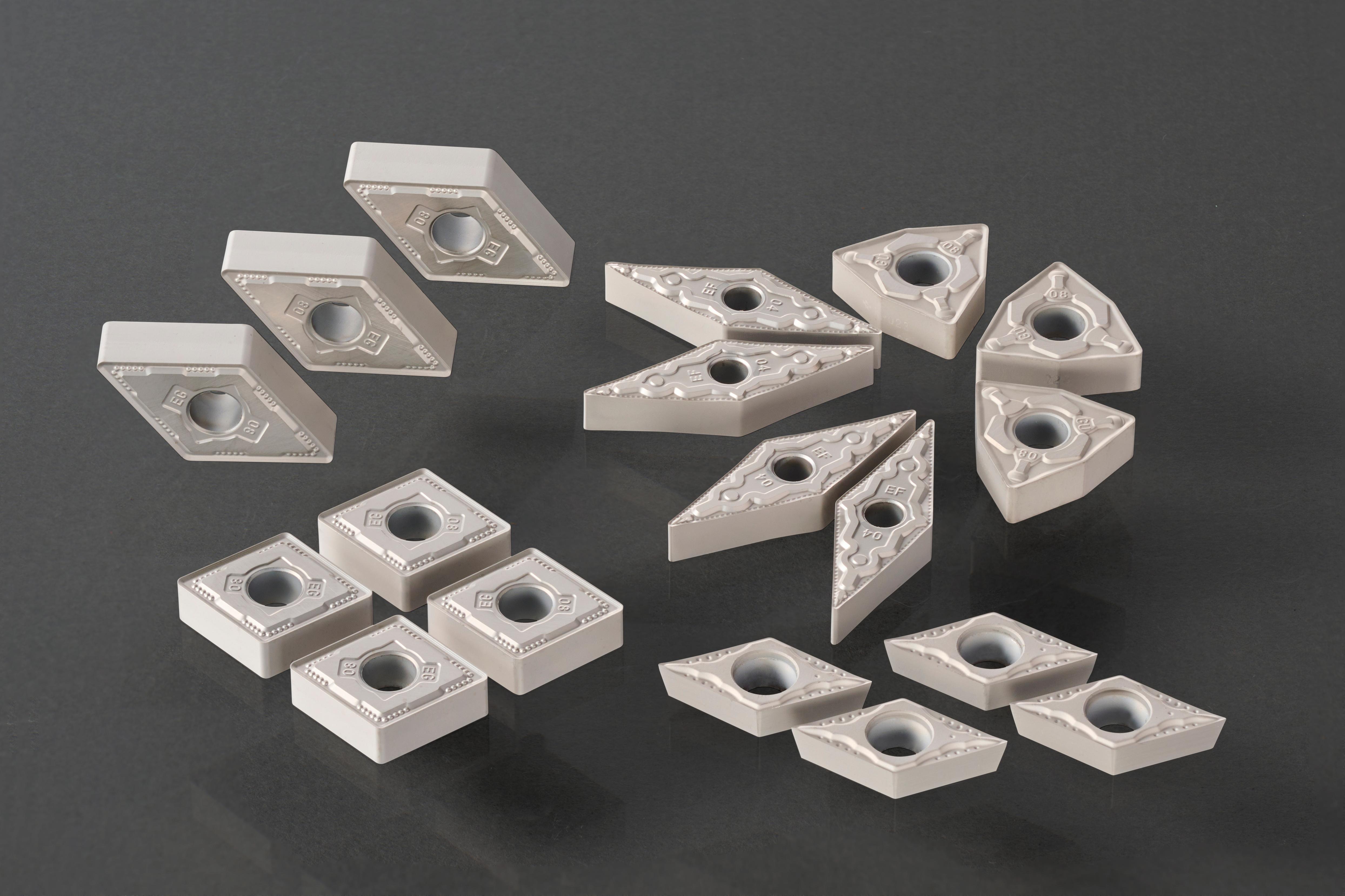

Insert: Total of 165 Cat. Nos.

*AC9115T: 92 Cat. Nos., AC9125T: 73 Cat. Nos.

3. Sales Plan

40 million JPY/year in the first year, 180 million JPY/year after 3 years

4. Standard Price

1,240 to 4,520 JPY (excluding tax)/pc

*PVD (Physical Vapor Deposition)

A method of depositing a thin physical coating on the surface of the target material in the vapor phase.