04 December 2024

Sumitomo Electric Starts Mass Production of Ultra-thin, Insulation-coated Powder Magnetic Cores with High Blocking Voltage

Sumitomo Electric Industries, Ltd. has started mass production of ultra-thin, insulation-coated powder magnetic cores with high blocking voltage, which enhance the output for axial flux motors.

We have been producing insulation-coated powder magnetic cores. Recently, we have developed and started mass production of powder magnetic cores with an ultra-thin, high-voltage insulation coating of 40 μm thickness and 5 kV insulation resistance. This new technology increases the number of turns of the copper wire wound around the stator by approximately 14% and allows efficient heat dissipation of the coil heat, enabling increased output for axial flux motors.

Drawing on our extensive accomplishments in mass production, we will continue to advance our material and process technologies for powder magnetic cores. By providing high-performance magnetic core components essential for various motors, we will add value to our customersʼ products.

Features of Insulation-Coated Magnetic Powder Cores

Motor performance can be enhanced by increasing the number of copper wire turns on the stator or efficiently dissipating heat generated in the coil during operation. Our insulation-coated magnetic powder core combines these methods through its unique properties, as listed below, and eliminates the need for conventional stator insulation materials such as insulating paper and resin bobbins. Thus, the product reduces the capital investment required for the process.

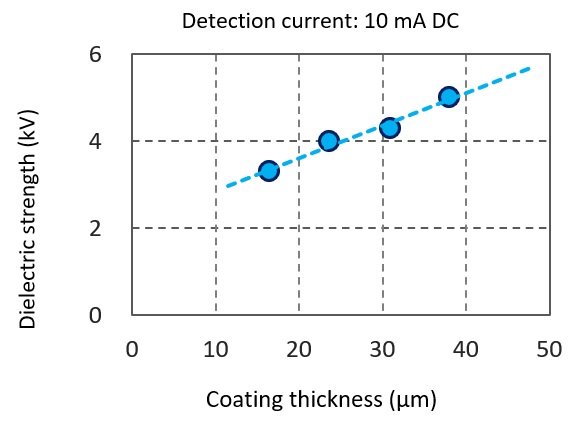

1. Insulation coating is as thin as 40 to 50 μm, allowing a large space (slot space) for copper wire winding.

2. The 40 μm thickness of the insulation coating provides high insulation with a dielectric strength of 5 kV.

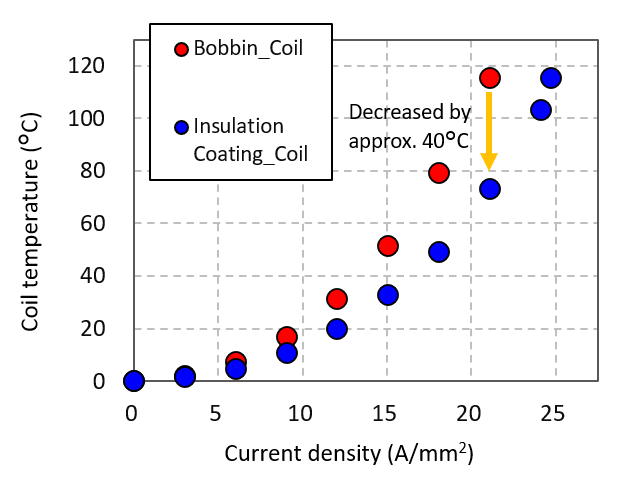

3. The heat generated by the copper wire (coil) is quickly dissipated to the magnetic powder core through the thin insulation coating, significantly reducing the coilʼs temperature rise.

Features of Axial Flux Motors and Our Magnetic Powder Cores

In recent years, the increasing demand for light and high-performance motors has attracted attention to the "axial flux motor," an innovative modification of the basic structure of conventional motors (radial flux motors) that increases output density while achieving a light and thin motor. Our powder magnetic cores (FMCM series) are made from iron powder covered with a nano-order insulation film, formed and heat-treated to exhibit excellent soft magnetic properties and a high degree of three-dimensional shape freedom. Thus, they are suitable for the stator cores of axial flux motors.

We are striving for technological innovation and continuously providing valuable products for our customers.

(Reference)

Features of Axial Flux Motors

https://sumitomoelectric.com/products/softmagneticcomposite/axialfluxmotor

Soft Magnetic Composite / Axial Flux Motors

https://www.youtube.com/watch?v=lG_qZSX0J_c