The Cross Linked Fluorine Resin FEX™

What is FEX™?

FEX : Crosslinked Perfluorinated Polyethylene

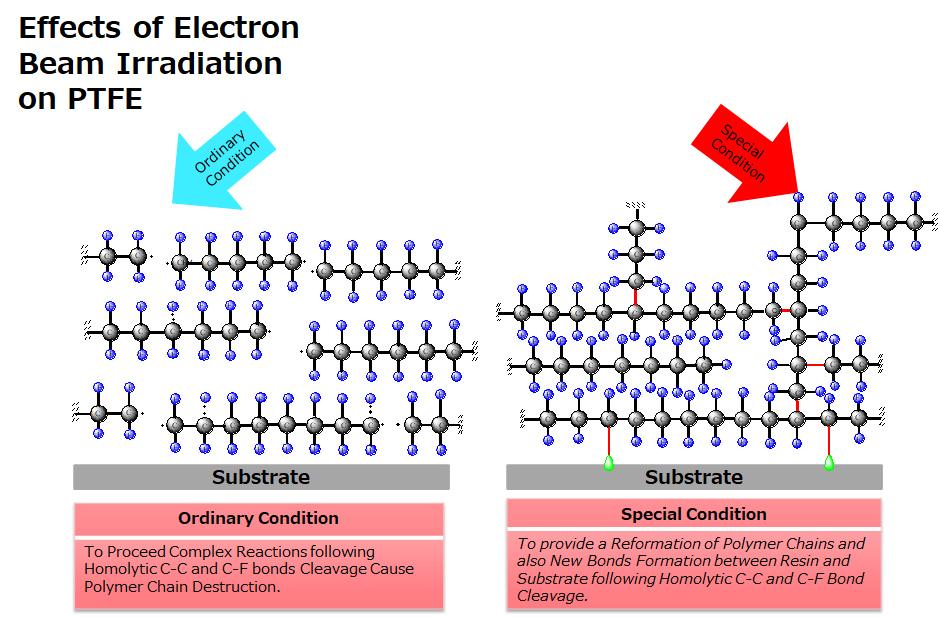

FEX™ is a functional fluororesin coating technology which takes advantage of the low coefficient of friction of conventional flurororesins while showing an exceptional improvement in wear resistance.

It is based on our state of the art electron beam cross- linking technology combined with our original fluororesin coating techniques.

Advantages

-

High Abrasion Resistance without Fillers

-

High Adherence to Substrates

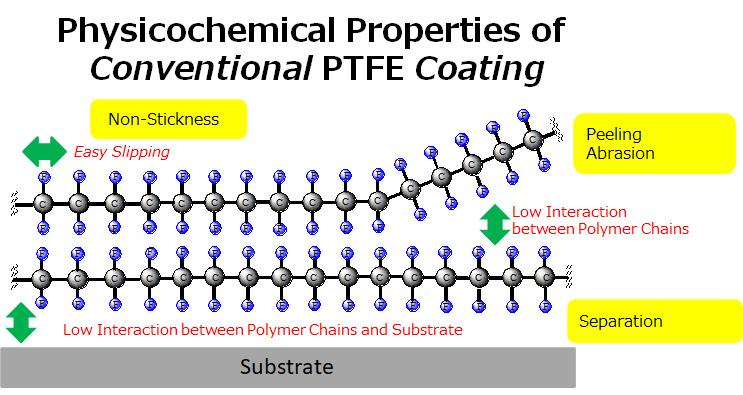

Principle

Applications of The FEX™ Coating

| Conventional PTFE Coating |

FEX®PTFE Coating |

|

|---|---|---|

| Abrasion Resistance | 1 | 1,120 |

| Adhesion to Substrate | Difficult | Adhesible |

| Dynamic Friction Coefficient | Minimum(0.06~0.1) | same |

| Thermo Stability | 260℃ | same |

| Chemical Stability | Stable | same |

| Flame Retardancy (Limiting Oxygen Index) |

Over 95% | same |

| Weatherability | Excellent | same |

| Permittivity(10³~10⁶Hz) D150 |

Minimum(2.1) | same |

| Dissipation Factor(10⁶Hz) D150 |

Minimum(2×10-³) | same |

| Pencil Hardness | HB | same |

Applications to split bushings

deep drawing bearing

Applications of The FEX™ Coating

Coating prior to Molding

FEX™ Coated metal plates are molded into optional shapes by press working.

Also, FEX Coated metal plates could be suplied.

Application to Slider Shafts

Coating on arbitrary shapes

FEX™ Coating is applicable to various shaped substrate.