Industrial Materials

22VISION Ideal state

We aim to be a global supplier of high performance and high functionality products that utilize the world’s top level materials technology.

Overview of Business

Copper wires are drawn with wire drawing dies. In our research and development work, we have taken the wiredrawing processes we have used for our copper wires and the powder alloys we use to develop our materials and applied them to other metals to create special steel wires. We have also applied the powder metallurgy technology we use to produce powder alloys and used it to develop sintered powder metal products.

Our cutting and grinding tools are made using the material technology we have developed based on our technology for making fine copper wires. We began with cemented carbide alloys and expanded our range to include other ultra-hard materials such as diamond and cubic boron nitride. Our tools are now used in all kinds of manufacturing around the world. Additionally, special steel wires that reinforce concrete structures and tires and sintered powder metal parts used primarily in automobiles are essential for the growth of society and industries. In response to the growing demand for lightweight automotive materials and the growth in the medical and aviation industries, the Sumitomo Electric Group will offer tangible forms of innovative solutions for customer and social challenges, drawing on our world-class materials development capabilities and production technologies.

VISION 2022 Mid-term Management Plan: Segment Strategy

FY2020 Results

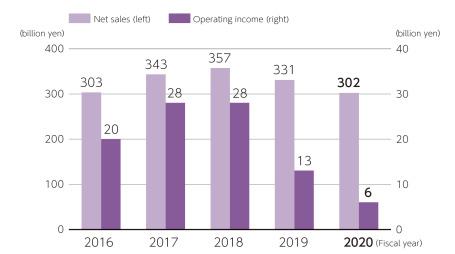

Demand for cemented carbide tools, diamond and CBN tools, sintered powder metal products, steel wire for springs, steel tire cords, and other products fell sharply, especially in the first half of the year, due to the impact of COVID-19, and sales fell 28,826 million yen, or 8.7% year-on-year, to 302,524 million yen. Due, in part, to deteriorating profitability resulting from a decline in plant utilization rates, operating income decreased by 6,765 million yen to 6,660 million yen.

Priority initiatives for FY2021

●For cemented carbide tools, we will strive to expand our market share by responding in a timely and accurate manner to recovery demand from the effects of the COVID-19 virus, as well as developing new tools for electric vehicle and aircraft components.

●For sintered powder metal products, we will strive to expand sales of electric vehicles and further strengthen the cost competitiveness of each manufacturing base globally with a view to future business development.

●As for prestressing steel wire and steel wire for springs, we will strive to improve profitability by strengthening our global manufacturing and sales structure as well as through new product development.

Examples of our initiatives to solve social issues

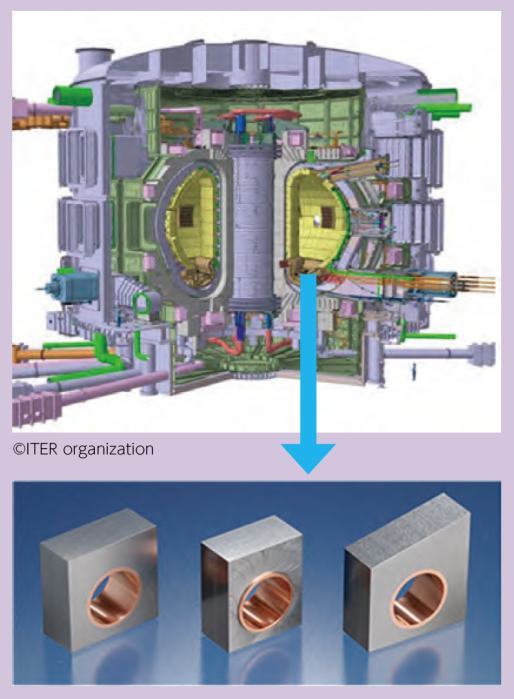

ITER (is one of the most ambitious energy projects in the world today)

One of our group companies, A.L.M.T. Corp. contributes to the development of the ITER which is a demonstration project for [nuclear fusion energy (expected to be a sustainable energy source that excels in terms of resources, environment and safety)] as a decarbonized energy, by supplying tungsten parts with superior thermal properties for the target of the diverter.